当前位置:网站首页>How to set up wireless PPI communication between Weiluntong touch screen and S7-200smart?

How to set up wireless PPI communication between Weiluntong touch screen and S7-200smart?

2022-08-02 12:01:00 【mydatai】

In the factory, a touch screen usually needs to establish communication with multiple PLCs, and the positions of each device are different.If wiring, it needs to be constructed in multiple places, which is more troublesome. In this case, it is more convenient to establish communication between the touch screen and the PLC by wireless.Because using the wireless PPI protocol has a fast response speed and does not require programming, only configuration is required, so it is more advantageous to use the PPI protocol network.However, the realization of wireless PPI communication requires a special wireless data terminal, and the matching of the setting parameters should also be considered during configuration.

This program takes Weiluntong touch screen as an example to introduce the realization process of wireless PPI communication between Weiluntong touch screen and two S7-200Smart PLCs.In this scheme, Siemens PLC dedicated wireless communication terminal DTD434M is used as the hardware device for realizing wireless communication.

I. Overview of the program

Through the European and American PLC dedicated wireless communication terminal DTD434M, the wireless PPI network can be realized stably and conveniently, without changing the network parameters or the original program, directly replacing the wired Rs485 communication.

Wireless Network Diagram ▼

Second, test equipment and parameters

● Touch screen: TK6071IQ × 1 set

● 200SMART model: CPU SR20 × 2 sets

● Wireless communication terminal: European and American PLC dedicated wireless communication terminal-DTD434MC × 3 pieces

● Data cable: Siemens PLC dedicated 485 cable × 1

● Touch screen data cable: Rs485 data cable for touch screen × 1 pc

● Master-slave relationship: 1 master 2 slaves

● Communication interface: Rs485 interface (two-wire system)

● Communication parameters: 9600, 8, E, 1

● Power supply: 9-24VDC

● Transmission distance: 100 meters, 500 meters, 1KM, 3KM, 20KM

Three, European and American PLC dedicated wireless communication terminal function detailed explanation

The wireless data communication terminal DTD434M has built-in RS232/RS485 dual interface, which can directly replace traditional wired solutions such as RS232/RS485 without programming.It can form a wireless measurement and control network with Siemens PLC, configuration software, man-machine interface, touch screen, measurement and control terminal and other industrial control products.

■ DTD434M main features:

◆ Directly replace the wired RS485 solution to realize wireless networking communication;

◆Full digital wireless encryption to ensure data security and reliability;

◆ DC 9~24V wide power supply voltage, the average working current is less than 50mA;

◆ Communication interface: RS232/RS485;

◆ Support standard serial protocol: Modbus RTU protocol, PPI protocol.

Four. Wiring method

1. Wiring between touch screen and Dataai wireless equipment

The first step: Connect the red wire of the Rs485 data cable dedicated to the touch screen to the A port of the DTD434MC; connect the black wire of the Rs485 data cable dedicated to the touch screen to the B port of the DTD434MC

Step 2: The last digit (K8-8) DIP switch in the wireless communication terminal setting switch is up

The third step: connect the antenna to the wireless communication terminal

Step 4: After all wiring is completed, supply power to the touch screen and wireless communication terminal

2.Connection between PLC and Dataai wireless equipment

5. Weiluntong touch screen realizes PPI master station

Open "Weiluntong touch screen 1 master 2 slave PPI routine.emtp"

1. System parameter settings

2. Touch Screen Screen Production

3. I point setting of No. 1 slave station

4. Q point setting of No. 1 slave station

5. I point setting of No. 2 slave station

6. Q point setting of slave station No. 2

7. Physical wiring diagram

Six, Siemens PLC realizes PPI slave station

1. PLC parameter setting

2. Set PLC address

Set the address of one PLC to 1 and the other to 2

Select "Parameter - Module Parameters - 485 Serial Port"

3. CPU Mode

Choose: RUN, download the program to the PLC

4. Physical wiring diagram

Seven, wireless communication test

1. Touch screen output signal

Use the button on the touch screen to signal the Q point of the No. 1 slave station to see if the Q point corresponding to the 200SMART is lit. If it is lit, it means that the communication is normal.

2. PLC input signal

Through the external signal to the No. 1 slave station I point, check whether the corresponding point on the touch screen is lit. If it is lit, it means that the communication is normal.

边栏推荐

猜你喜欢

力扣35-搜索插入位置——二分查找

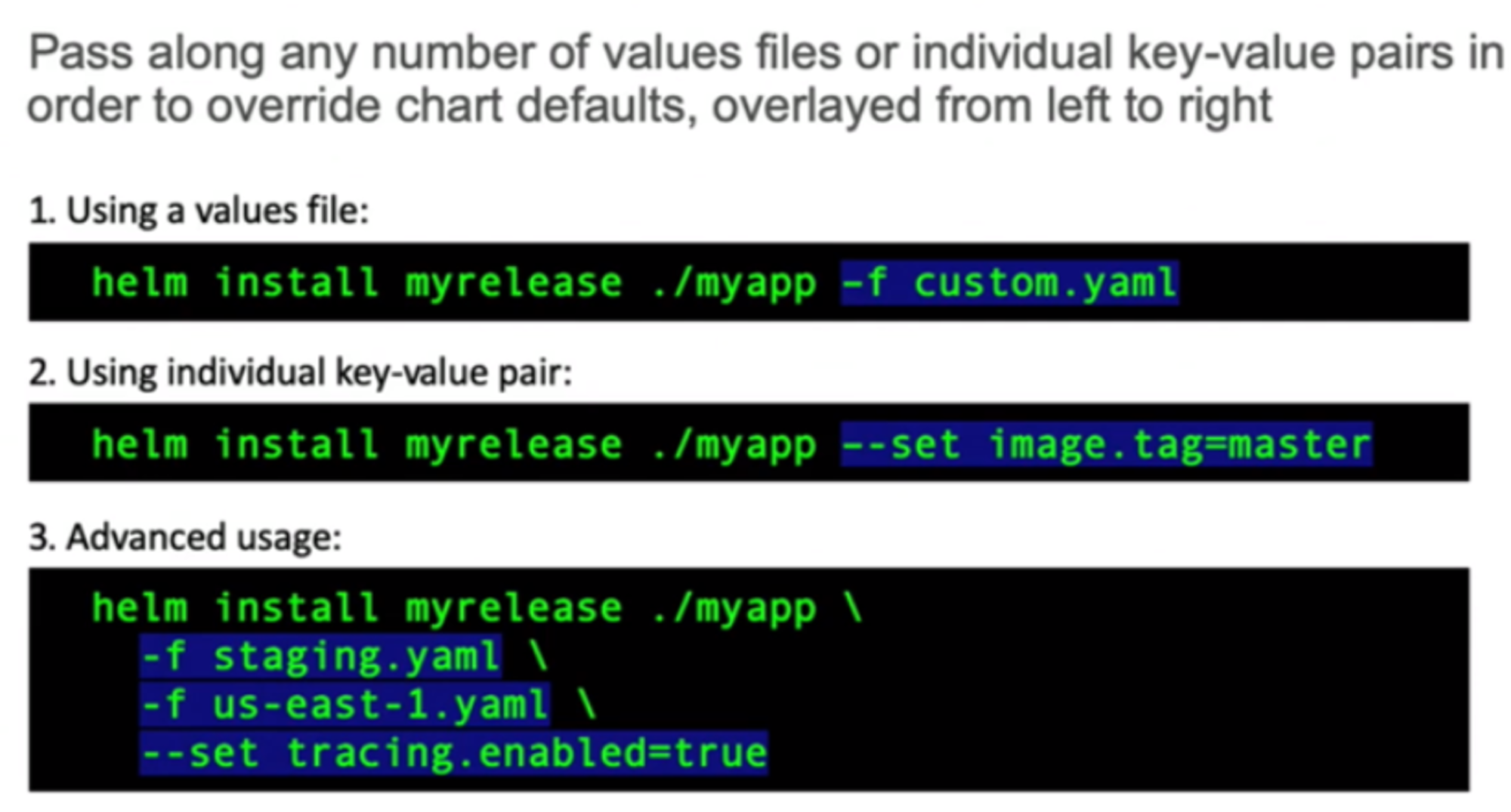

云原生(三十) | Kubernetes篇之应用商店-Helm介绍

![[kali-information collection] (1.8) ARP reconnaissance tool _Netdiscover](/img/04/f477cd8726d147b892f6050d46c312.png)

[kali-information collection] (1.8) ARP reconnaissance tool _Netdiscover

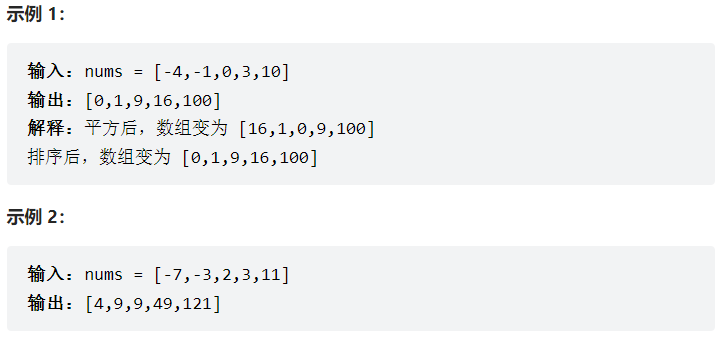

力扣977-有序数组的平方——暴力法&双指针法

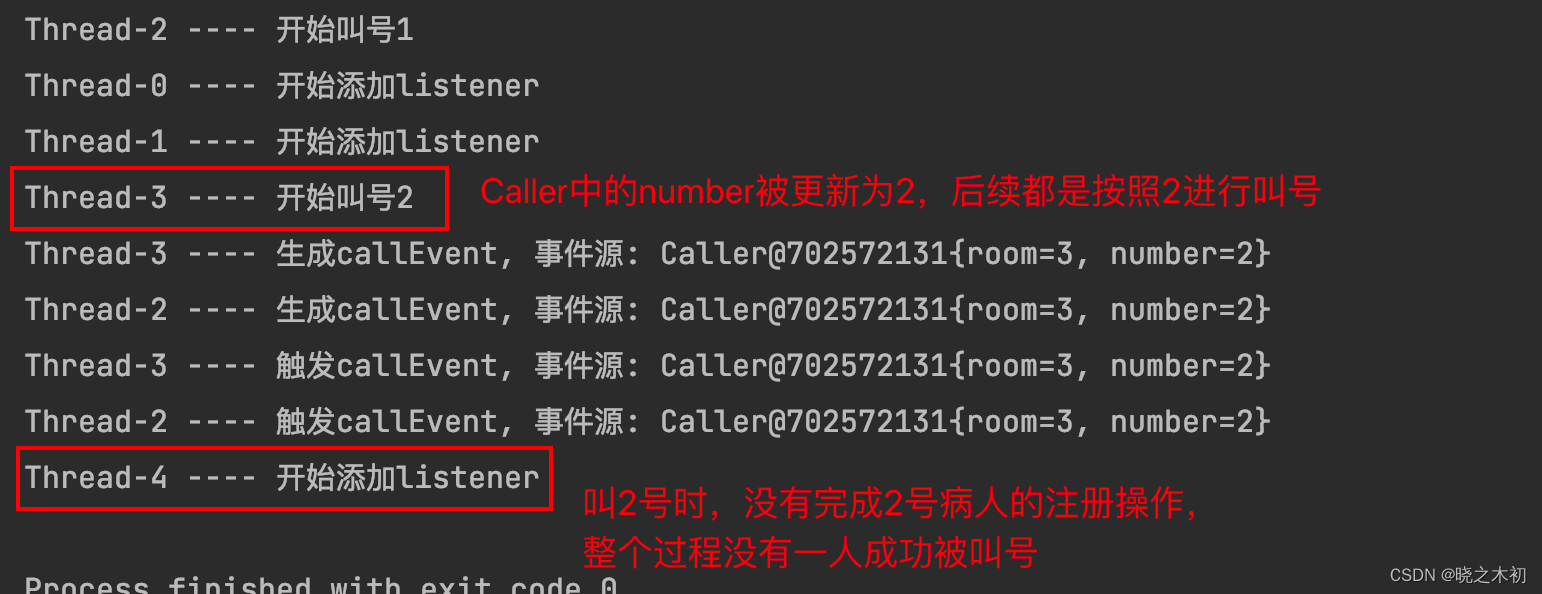

观察者(observer)模式(二) —— 实现线程安全的监听器

【kali-信息收集】(1.9)Metasploit+搜索引擎工具Shodan

5G网络切片技术

Create an application operation process using the kubesphere GUI

FinClip | 来了, 2022 年 7 月更新大盘点

NVIDIA NeMo Metrics 轻量性能采集系统

随机推荐

Likou 209 - String with the Minimum Length - Sliding Window Method

看我如何用多线程,帮助运营小姐姐解决数据校对系统变慢!

太厉害了,终于有人能把TCP/IP 协议讲的明明白白了

使用kubesphere图形界面创建一个devops的CI/CD流程

SuperSlide系列之轮播图

JSP中如何正确的填写include指令中的file路径呢?

pyqt5连接MYSQL数据库问题

基于threejs的商品VR展示平台的设计与实现思路

The use of QListView

Failure Analysis | A SELECT statement crashes MySQL, what happened?

记录代码

打破千篇一律,DIY属于自己独一无二的商城

如何在 UE4 中制作一扇自动开启的大门

Leek 151 - Reverse words in a string

【kali-信息收集】(1.9)Metasploit+搜索引擎工具Shodan

Free Chinese-English Translation Software - Automatic Batch Chinese-English Translation Software Recommended Daquan

三种实现分布式锁的方式

Crack detection technology based on deep learning

npm WARN config global `--global`, `--local` are deprecated. Use `--location解决方案

基于深度学习的裂缝检测技术