当前位置:网站首页>Six axes of calibration service

Six axes of calibration service

2020-11-09 16:11:00 【Test those things】

This issue is from Keysight, There is no change in the original text !

----------------------------------------------

Abstract

Choosing a calibration service provider seems to be a very simple matter , It seems that calibration is just calibration , As long as the supplier has a normal business license (ISO9000 registration 、ISO17025 Qualification, etc ) So no matter what kind of service or supplier you choose , The services provided should be similar . But that's not the case , Due to the lack of regulation of calibration services , As a result, the service provided and the calibration results are uneven .

introduction

To help illustrate the difference , Instruct purchasers who are not familiar with the technology to understand the importance of all aspects of calibration services , We split the calibration service into six different axes , Each axis affects the practicality of calibration or the direct or indirect cost of choosing calibration services . Each axis is discussed in depth in this paper , They are :

1. The scope of the test ( How many parameters to test ? How many test points need to be tested for each parameter ?)

2. Information provided ( What data is provided ? Is it the data before adjustment or after adjustment ?)

3. Measurement uncertainty ( How accurate is the test ?)

4. cycle ( How often do you need to calibrate ? Can you change this time interval ?)

5. Speed ( How long can you tolerate not using the instrument ?)

6. Supporting services ( What are the supporting solutions and services ? What items are included in these services ?)

axis 1. Test range

Obviously , The more comprehensive the instrument is tested , The more confident the instrument performs the measurement . Generally speaking , The manufacturer recommends which parameters should be tested and the number of test points that should be checked for each parameter . However , It is not uncommon for low-cost suppliers to ignore many of these tests . Since there is generally no technical agency in our industry to specify the scope of testing required to perform legal calibration , Therefore, the above practice does not violate any regulations or guidelines .

There are three main reasons for ignoring some of these tests :

1. The supplier does not have the equipment to perform the test

2. The test is too complicated , Execution time is too long , Or require specialized skills

3. The negotiated price does not allow all tests to be performed

Usually this means that calibration services cannot adequately test important parts of the instrument , As a result, , Users may be unaware of , Measurements performed with these devices may be wrong .

When testing products with these devices , There can be two harmful situations :

1. Qualified products may be judged as unqualified during the test , Lead to costly rework , Improve the rework department NFF( No fault found ) Probability ( This is a key indicator in the production cycle ).

2. Unqualified products may be judged as qualified during the test , This leads to an increase in the number of warranty returns , The cost of repair has increased , At the same time, it damages the company's image and reputation .

example

A company sent a scalar analyzer probe to a famous company for calibration . The company's calibration process is at the low end of the range 、 Middle end and high end three point frequency test equipment . The test report shows that , The performance of the equipment is in accordance with the specifications , And issued a calibration certificate . But the customer had strange measurements when using the device , So it sent the device to Shide Technology , Calibrate again .

The program of SciTech is to use sweep frequency to test the whole range of the equipment . This test clearly shows , The probe has problems at frequencies not tested by the first supplier . If you use sweep calibration from the beginning , Customers will save a lot of time and money .

A metaphor can better explain all this : On a sailing ship , The watchman looked out through the mast , He first looked through a telescope at Zhengdong , And then I took a look at due north , Look at the west again , Finally, the report says “ I didn't see the ship ”.

exception

It must be pointed out , If you control it properly , Reducing testing is not necessarily a bad thing . For devices used in specific applications , If only part of the well-defined functions of the instrument are used , Reducing testing is certainly acceptable , And it could offer a big advantage , Because it can focus calibration on these specific functions or ranges . Especially if compared to full calibration , More comprehensive testing of these areas .

however , This method may not be suitable for multi-purpose or general purpose equipment .

axis 2. Information provided

Information provided by the calibration supplier relating to the tests performed during the calibration process , It's the basis for users to make many decisions , So get the information you need 、 At the same time, it is very important to ensure the accuracy of the information .

Users want calibration suppliers to provide comprehensive data , Show the performance of the device at each test point . these

The information indicates the scope of the test , Can be used to perform an objective comparison between suppliers .

But the value of information is more important . When the calibration supplier found that the performance of the instrument fell outside the specified allowable error range (OOT—— Out of tolerance / Out of tolerance ) when , This means that the user may have used the device to perform some unqualified measurements . To analyze whether this will impair the effectiveness of these completed tests , You have to know which parameters the instrument falls outside the allowable error range , And how far out of range . Then you can decide if corrective action is needed , Such as retesting or recalling your product . Without this information , You may not know that the test has made errors , Or maybe the calibration report simply states that the device is out of tolerance , But there was no support

data , Then you won't be able to make informed decisions .

The really useful data is when the calibration supplier receives the equipment , A complete set of performance test information collected by performing measurements on the equipment . During this test , Any adjustment to the device will destroy the integrity of the test in the subsequent program . The second set of data collected after adjustment will confirm that the instrument is within the allowable error range after adjustment , To provide confidence that the device will be used to perform tests in the future .

Another key message is “ Measurement uncertainty ”. Its simplest form is a statement , State that the equipment used to test the user's instrument is at least as accurate as the calibrated instrument 4 times .(4 Generally considered to be the lowest test accuracy ratio for calibration services , namely TAR).

The calibration supplier will provide more detailed uncertainty information through the summary table , The parameters and associated uncertainties are listed . Parameter values can be relative values ( Such as ± 0.5%), It can also be the absolute value of the unit of measurement ( Such as ± 0.2 mV).

Next to the measurement data is the most detailed uncertainty information , Ideally , The measured values shall be provided in the same item 、 Technical index range and uncertainty information .

axis 3. Measurement uncertainty

The measurement uncertainty can indicate the quality of calibration service testing , That is to calibrate the accuracy of the measurements performed by the supplier . This axis is invisible , Unless the measurement uncertainty is known , But it can have a significant impact on whether calibration is really useful .

The uncertainty clearly indicates whether the supplier has the technical qualification to perform the measurement . The uncertainty can be evaluated by the supplier itself , It can also be assessed by a certification body . Recognized uncertainty is more important , Because it is independently evaluated by a recognized certification body , Such as the United Kingdom UKAS、 Japan JCSS、 Germany DKD、 China CNAS And the U.S. A2LA wait .

You can examine the best measurement uncertainty data from an accredited Calibration Laboratory , Because the information is public , It is usually available through the website of a certification body . Through this information , You can know the technical level of the laboratory , And compare the ability of laboratories to perform certain measurements . This allows you to conclude that some laboratories may not have the real qualifications to perform certain calibrations .

In terms of certification , Some laboratories may only be certified on certain tests , But accepted equipment calibration beyond the scope of certification , This is not uncommon . They may only get one measurement certification , But they're going to show the certificate , Claiming that they are a certified Laboratory , And in fact, they don't have the ability to calibrate most instruments .

Illustrate with examples

By assessing the UK calibration supplier's certification arrangements or scope on two comparable basis measurements , You can see very interesting results .

The measurement we chose was 10 MHz The frequency and 1 V DC. This information comes from the UK certification service (UKAS) Website .

stay 10 MHz Under the circumstances , The uncertainty range of certification is very large . The best range of uncertainty is 10-12, The worst way to reach 3 x 10-6. So when measuring 10 MHz when , The most accurate results may also have uncertainties ± 0.00001 Hz, In the worst case, the uncertainty may even reach ± 30 Hz. Due to the technical specifications of most crystal oscillators ± 30 Hz Be narrow , So obviously , The company's calibration of crystal oscillators or instruments with certain frequency measurement accuracy is meaningless .

stay 1 V DC Under the circumstances , The range of uncertainty is relatively narrow , But it's still very obvious , The best is 4 x 10-7, The worst is 2 x 10-5. The resolution of many digital multimeters is 6½ position . in other words , It should be able to measure 1 V DC Is shown as 1.000000 V( That is, accurate to 1 Microvolt ).4 x 10-7 The uncertainty will be realized 0.4 Microvolt accuracy , This is accurate enough for the measurement task .2 x 10-5 Uncertainty can only be achieved 20 Microvolt measurement accuracy . In this case , The last one on the multimeter is completely untrustworthy .

It should be noted that , released “ Best measurement qualification ” It is not equivalent to the actual uncertainty specified for the calibration of a product . By comparing some typical certificates / Report examples , It allows us to understand the essence of the problem from another perspective .

axis 4. Calibration cycle

The calibration cycle is how often the instrument is calibrated . In general, the manufacturer recommends the calibration cycle for each instrument , It's usually a year or two . This is based on the average drift rate of various components . In the development process , What designers are most concerned about is the design with the least drift , But drift is a factor that cannot be completely eliminated , That's why calibration services are essential .

In order to analyze whether it is possible to calibrate without following the manufacturer's recommended period , You need to know two things :

1. Calibration history of an instrument

2. The use of instruments

The first point is to refer directly to the information provided by the calibration service discussed earlier ( axis 2). A widely accepted algorithm is , If you calibrate it three times in a row , The technical specifications of the instrument are all qualified , Then the calibration period can be relaxed appropriately . Empathy , If you calibrate twice in a row , We need to adjust the instrument , Then the calibration cycle should be shortened . And so on .

The second point is about risk . If the measurement performed by the instrument is critical , Then the calibration cycle must be shortened , To reduce the risk of poor measurement results . If the measurement results are not good or bad , Then the calibration period can be extended appropriately .

When both risk and calibration history are important , An efficient cycle management solution can be adopted , This minimizes the risk of deterioration of key measurement results , Control costs at the same time .

axis 5. Speed

On time at school , Generally, the instrument needs to be transported away from the user's place of use , Send it to another place for calibration, which usually takes a week or more to stop using the instrument . in other words , The user either stops what the instrument is doing , Or in a critical transactional environment , Buy or rent a spare instrument .

Knowing that the instrument will be moved for two weeks , It means you can plan ahead , Arrange for the use of spare or rental instruments . But if the two weeks promised by the supplier become three weeks or more , The cost will be greatly increased , You will lose control . therefore , Users would like calibration suppliers to promise a very short delivery turnaround time , It must also be able to deliver on promises reliably .

If the company can provide on-site calibration service , You can shorten the turnaround time to a few hours , In fact, it's just the time it takes to calibrate . This service may be expensive , But compared with the cost savings of purchasing and leasing spare instruments , The added cost is not much .

I want to remind you that . Field calibration seems to be an ideal solution , However, it is still necessary to ensure that the calibration supplier's technical level can meet your needs . Companies that provide on-site calibration services usually offer only a fraction of the tests , It may also bring a lot of measurement uncertainty . Only when they arrive at your place , You will find that , They carry limited testing equipment , The ability to test is even more inadequate .

Whether it's in the service center or at the customer site , We can provide high quality calibration service of the same standard .

axis 6. Supporting services

When it comes to calibration costs , The price of basic services is usually the main consideration . But if you choose supporting services , It can reduce the hidden cost , For example, to submit an order 、 Pay the invoice and other related costs , Or reduce the service price by signing a service agreement .

Is Germany technology to provide a wide range of supporting services , We hope to help you reduce the direct and indirect costs of purchasing calibration services . Many services can spread the service charge evenly over a year , Avoid peaks and lows in your spending .

There are other factors to consider in this regard . Shipping costs and routine repair services should be considered . If these items are included in the supporting services , Then you'll save a lot of money . conversely , The extra cost will surprise you .

example

A company calibrated AVO Meter ( Universal Analog Multimeter ) The quotation is every time 15 dollar . After a while , The customer found out , His AVO The instrument calibration fee has always been 40 dollar .

The customer didn't know until he asked , stay AVO The battery needs to be replaced during instrument calibration . According to the rules of this supplier , Replacing the battery is equivalent to a repair service , Additional charge per visit 25 dollar .

In this case , Although the amount of expenses per occurrence is very small , but 12 Months add up to , The total amount will be very considerable .

Conclusion

In the center of the six axes , Each axis affects the cost and quality of calibration services . I hope this article can help you make informed decisions , Not exactly on the seventh axis ―― The price will decide .

It's the same as shopping , You get what you pay for . Understand the content of calibration service and its significance to your company , Can make your decision more scientific , Little detours .

disclaimer :

The official account is purely personal account , Only for the purpose of technology sharing and exchange .

The information in this issue comes from Keysight, If you intrude, please delete the message immediately , thank you !

This article is from WeChat official account. - Test those things (Jackiy_455750304).

If there is any infringement , Please contact the [email protected] Delete .

Participation of this paper “OSC Source creation plan ”, You are welcome to join us , share .

版权声明

本文为[Test those things]所创,转载请带上原文链接,感谢

边栏推荐

- MES system is different from traditional management in industry application

- cad教程 cad2016安装教程

- Cad2016 download autocad2016 download installation detailed tutorial CAD Download

- [share] interface tests how to transfer files in post request

- Set two ways of background image, and solve the mobile phone background image highly adaptive problem

- Explain three different authentication protocols in detail

- 会展云技术解读 | 面对突发事故,APP 如何做好崩溃分析与性能监控?

- js字符与ASCII码互转的方法

- Echart sets the spacing between columns

- 高质量的缺陷分析:让自己少写 bug

猜你喜欢

如何使用Camtasia制作动态动画场景?

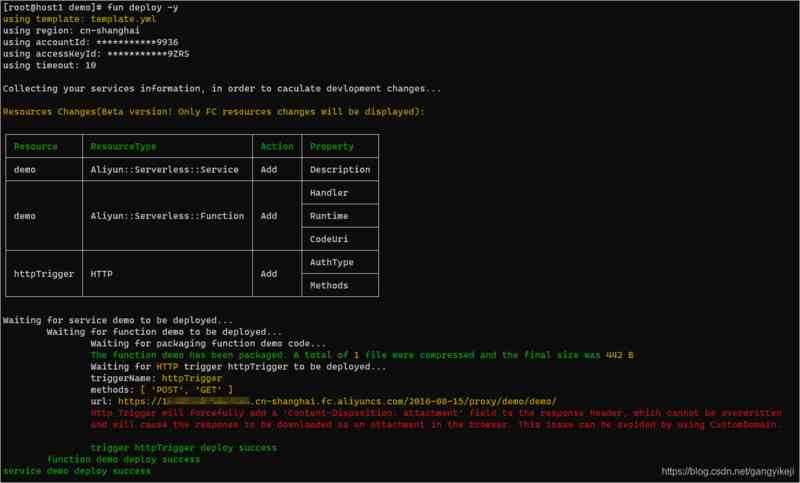

Function calculation advanced IP query tool development

融云完成数亿人民币 D 轮融资,将持续打造全球云通信能力

Cad2016 software installation tutorial

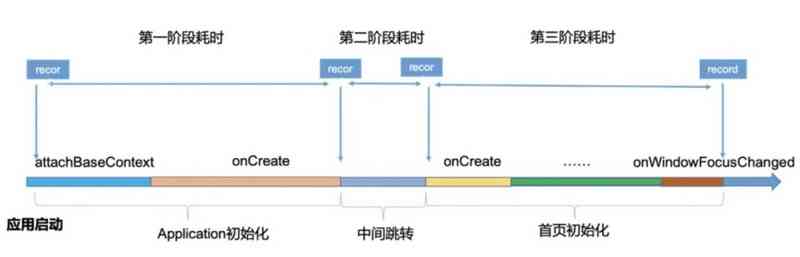

会展云技术解读 | 面对突发事故,APP 如何做好崩溃分析与性能监控?

你的钱为什么会被转走,这篇文章告诉你答案

嘉宾专访|2020 PostgreSQL亚洲大会阿里云数据库专场:王健

深入探索 Android Gradle 插件的缓存配置

Toolkit Pro助力界面开发:缩短项目开发周期,快速实现具有现代功能区样式的GUI

知识图谱描边1.1——从NER上手

随机推荐

Colleague notes - small program entry point

Detailed explanation of ipfsapp development method of biaofen IPFs mining machine app software development software

Application of pull wire displacement sensor in slope cracks

jackson、fastjson、kryo、protostuff等序列化工具性能对比

浮点数之间的等值判断

Program simulation perceptron algorithm (gradient descent method sklearn.linear_ Perception method in model)

设置背景图片的两种方式,并解决手机端背景图片高度自适应问题

5 minutes get I use GitHub's five-year summary of these complaints!

CAD2016下载AutoCAD2016下载安装详细教程CAD下载

「代码整洁之道-程序员的职业素养」读书笔记

Implement printf function by yourself

Application and practice of native map and web fusion technology

你以为学编程很简单吗,其实它很难!你以为学编程很难吗,其实它很简单!

The internal network penetration of raspberry is built and maintained. No server is required for intranet penetration

. net report builder stimulsoft Reports.Net Release the latest version of v2020.5!

函数计算进阶-IP查询工具开发

如何使用Camtasia制作动态动画场景?

AE(After Effects)的简单使用——记一次模板套用的过程

知识图谱描边1.1——从NER上手

Restart the heap_ uaf_ hacknote