当前位置:网站首页>Practical example of propeller easydl: automatic scratch recognition of industrial parts

Practical example of propeller easydl: automatic scratch recognition of industrial parts

2022-07-07 12:58:00 【Paddlepaddle】

Baidu Flying propeller EasyDL Provide zero threshold for enterprise developers AI Development platform , One stop support for smart tagging 、 model training 、 Service deployment and other functions , Built in rich pre training model , Support for public clouds / Local server / Flexible deployment on the device side , It has been used in industry 、 retail 、 manufacture 、 Medical treatment and other fields .

Automatic scratch recognition of industrial parts

Through training object detection customization AI Model , To achieve for “ Scratches on industrial parts ” Intelligent recognition of , It is widely used in industrial quality inspection 、 Intelligent manufacturing and other fields .

Project description

Business background

A factory is mainly engaged in the production and processing of various workpieces , Because the factory production environment is complex , There are scratches in the production process of the workpiece 、 Bump 、 Possibility of making omissions , Defective goods should be treated as defective products , Do not enter the market .

Business difficulties

The precision of defect quality inspection is required to be high , Defects are usually subtle and difficult to find , The traditional manual quality inspection method is inefficient , Long time operation is prone to visual fatigue and false detection 、 Phenomenon of missing inspection . Low quality inspection efficiency will directly affect the factory's production capacity and delivery efficiency .

Solutions

To improve production capacity and quality inspection accuracy , The factory decided to intelligently empower the quality inspection production line , adopt AI Realize automatic identification of defects + Manual review method , Improve the efficiency of ex factory quality inspection . come to know Flying propeller EasyDL Provides zero threshold AI Development function , Model training can be completed quickly without knowing the basis of the algorithm , The factory passed EasyDL The object detection task type provided by the platform is quickly trained in the following steps , High precision scratch quality inspection of production workpiece is obtained AI Model and put it into practical business application , Based on this intelligent quality inspection scheme , The quality inspection manpower invested by the enterprise every year is reduced 60%, The efficiency and accuracy of quality inspection have been greatly improved .

Tips : For workpiece surface scratch recognition scene , Multiple scratch defects may appear in a single picture , The number of scratches needs to be identified , Therefore, the object detection model is selected .

Data preparation

Data collection and import

The factory selects historical defect data from the original production environment, about 300 Zhang , When preparing training data, we should pay attention to keeping consistent with the data generated by the actual production scene as far as possible , Like light 、 brightness 、 Shooting angle, etc , Only when the objective factors are consistent, the trained model will have higher applicability and effect in practical application . for example , The angle of the camera deployed in the actual quality inspection production line to the parts is overhead , that , When collecting data, you also need to collect the original pictures from the same angle . If the original data obtained by the enterprise has no annotation information , You can choose to import unmarked information in the platform and then press one key to import , for example , You can type the original image into a compressed package , The specific import path is as follows :

meanwhile EasyDL It also provides a variety of other data import methods , You can choose different import methods according to your usage habits , for example , You can upload the picture to the network address first ( for example , Baidu SkyDrive 、 Baidu BOS etc. ), Copy the corresponding address link to complete the quick import , It is suitable for cases with large data magnitude , Help you shorten the import time .

Data tagging

The original image needs to be marked , Before model training . The data marking process should be as close to the defect characteristics of scratches as possible , Make sure that all defects are contained in the rectangular box and that the rectangular box is not too large than the defect size , The following are examples of correct annotation and wrong annotation .

Tips : When your annotation workload is large , You can choose to turn on smart annotation , That is, you only need to mark 30% Pictures of the , The remaining 70% The picture of will automatically label you .

model training

After training data preparation , You can create it by clicking 【 Creating models 】 Enter the basic information and complete the model creation , Click on 【 Training models 】 Start training . A model can cover multiple versions , One training produces one version , You can customize the version management according to your business needs . Considering that industrial quality inspection scenarios usually pay more attention to prediction efficiency , The prediction efficiency of the model will directly affect the quality inspection efficiency , Therefore, it is recommended that you choose EasyEdge Local deployment - The server - Ultra high precision algorithm . The advantages of this scheme are : The local deployment method can effectively save the time required for the upload of prediction data and the distribution of prediction results , Greatly improve the prediction efficiency and then increase the production capacity , Ultra high precision algorithm can maximize the effect of the model , Here's the picture :

Model deployment

Local deployment requires local computing power to carry the model deployment and prediction process , To ensure the prediction performance of the model , The factory chose the one with sufficient computing power T4 Server as local computing power , Therefore, it is necessary to publish the model as a model suitable for the hardware SDK. meanwhile EasyDL The platform still supports many other hardware types , You can choose the corresponding operating system and chip type according to your actual business needs , Here's the picture :

After the model is released , Can be found in 【 Pure offline service 】 Found published models in SDK, Download and 【 Get the serial number 】 After activation, it can be deployed in the terminal application .

The enterprise will AI The model is applied to the actual scene, hoping to realize the automatic sorting of defective workpieces , In the quality inspection production line, each workpiece is photographed by a professional camera , The captured pictures are transferred to the prediction server for quality inspection , When defects are detected in the current workpiece picture , The defective workpiece is grabbed by the mechanical arm and stored in a specific area for manual review .

Effect optimization

After model training , adopt EasyDL The overall effect of the model can be viewed in the automatically produced evaluation report , In this factory scenario, the defect characteristics are relatively consistent and the scenario is fixed , The overall effect is better . If the effect is not good, you can check the error examples of different labels to locate the reasons for the poor performance under this label . for example , By looking at the error examples , Pictures with wrong predictions are usually taken during periods of insufficient light , For optimization suggestions, we need to supplement the data in the case of insufficient lighting Improve model effect , Here's the picture :

common problem

problem 1:EasyDL Images provide a variety of training tasks , Why choose the object detection task type in this scenario ?

at present EasyDL Images provide image classification 、 Object detection 、 There are three types of tasks in image segmentation : Image classification is applicable to scenes with a single subject or state in the picture ; Object detection is applicable to scenes with multiple subjects and the need to identify the location of the subjects ; Image segmentation can locate multiple subjects and needs to be located at the pixel level of the subject . For the scratch inspection scenario , Multiple defects may appear in a single picture , Defects do not need to be located at the pixel level , Therefore, it is more appropriate to select object detection .

problem 2: How to collect industrial quality inspection scene data ?

The data is AI Prerequisites for model training , The training data in the industrial quality inspection scene usually comes from the historical stock data of the image acquisition equipment on the industrial production line , therefore , If image acquisition equipment has not been built on the production line, priority should be given to the construction of image acquisition equipment , Based on the collected image data AI model training .

problem 3: How to solve the problem of too few defect samples ? EasyDL The platform provides data enhancement strategies , in the light of EasyDL The platform provides data imbalance strategies , The existing defect pictures can be expanded by data enhancement strategy , And then maximize the utilization of limited data , Complete the configuration on your model training page .

边栏推荐

- 【无标题】

- Aosikang biological sprint scientific innovation board of Hillhouse Investment: annual revenue of 450million yuan, lost cooperation with kangxinuo

- Connect to blog method, overload, recursion

- Day-17 connection set

- Day21 multithreading

- [difficult and miscellaneous]pip running suddenly appears modulenotfounderror: no module named 'pip‘

- Layer pop-up layer closing problem

- Cmu15445 (fall 2019) project 2 - hash table details

- 货物摆放问题

- Sample chapter of "uncover the secrets of asp.net core 6 framework" [200 pages /5 chapters]

猜你喜欢

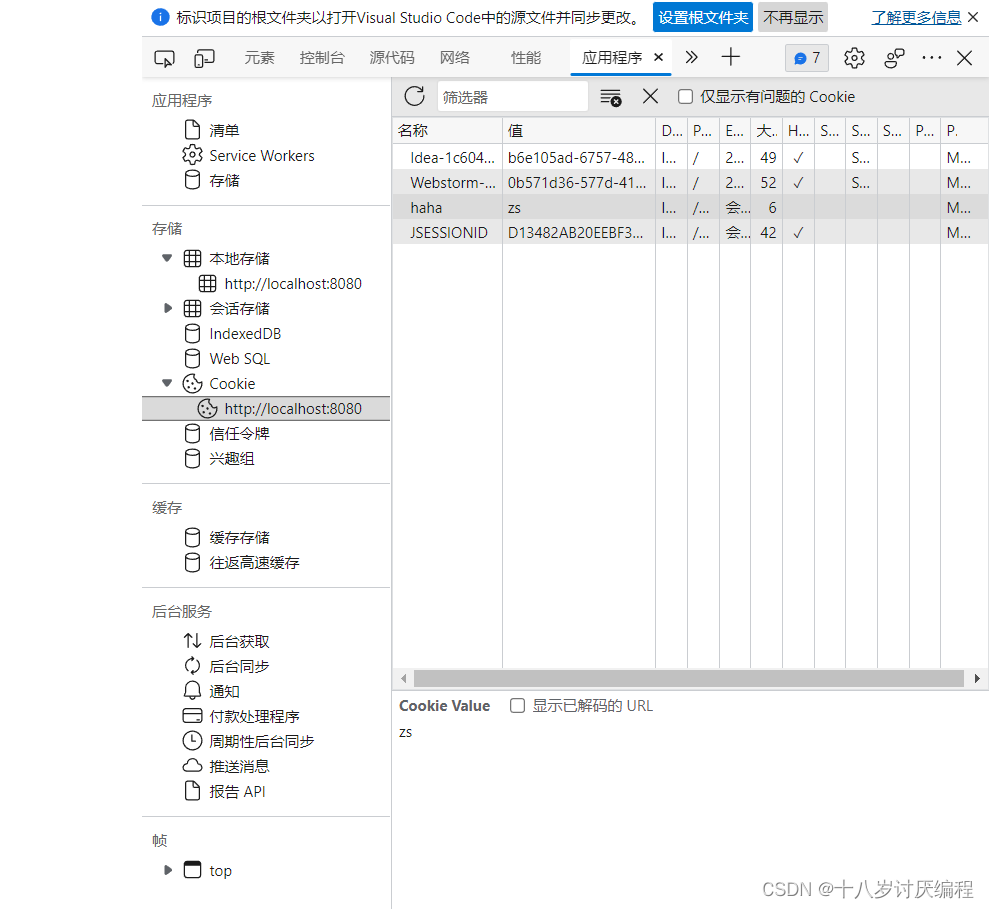

Cookie

Lingyunguang of Dachen and Xiaomi investment is listed: the market value is 15.3 billion, and the machine is implanted into the eyes and brain

2022 polymerization process test question simulation test question bank and online simulation test

ACL 2022 | small sample ner of sequence annotation: dual tower Bert model integrating tag semantics

Master formula. (used to calculate the time complexity of recursion.)

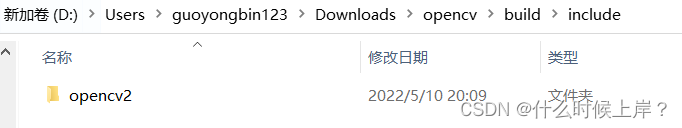

Visual stdio 2017 about the environment configuration of opencv4.1

![[statistical learning method] learning notes - logistic regression and maximum entropy model](/img/f7/857d053cc2cee81c24919aafab3c6e.png)

[statistical learning method] learning notes - logistic regression and maximum entropy model

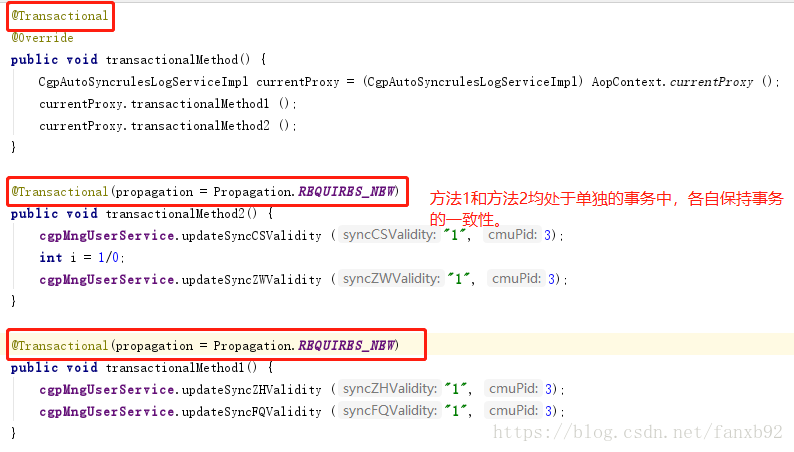

How to apply @transactional transaction annotation to perfection?

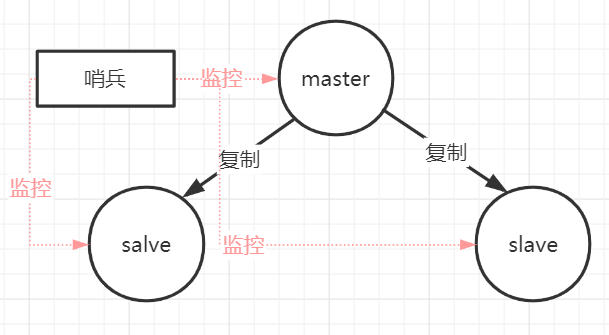

Talk about four cluster schemes of redis cache, and their advantages and disadvantages

2022 examination questions and online simulation examination for safety production management personnel of hazardous chemical production units

随机推荐

Sample chapter of "uncover the secrets of asp.net core 6 framework" [200 pages /5 chapters]

Day-24 UDP, regular expression

【从 0 开始学微服务】【02】从单体应用走向服务化

企业级自定义表单引擎解决方案(十二)--体验代码目录结构

在字符串中查找id值MySQL

Cmu15445 (fall 2019) project 2 - hash table details

2022a special equipment related management (boiler, pressure vessel and pressure pipeline) simulated examination question bank simulated examination platform operation

Connect to blog method, overload, recursion

Master公式。(用于计算递归的时间复杂度。)

About IPSec

How to reset Google browser? Google Chrome restore default settings?

Four functions of opencv

NPM instal reports agent or network problems

Common knowledge of one-dimensional array and two-dimensional array

[learn wechat from 0] [00] Course Overview

Charles: four ways to modify the input parameters or return results of the interface

[pytorch practice] use pytorch to realize image style migration based on neural network

The URL modes supported by ThinkPHP include four common modes, pathinfo, rewrite and compatibility modes

Leetcode skimming: binary tree 20 (search in binary search tree)

mysql怎么创建,删除,查看索引?