当前位置:网站首页>High end electronic chips help upgrade traditional oil particle monitoring

High end electronic chips help upgrade traditional oil particle monitoring

2022-07-05 07:40:00 【particle counter 】

Abstract : This paper analyzes the influence of hydraulic oil performance and pollution on lubrication and wear failure of hydraulic equipment , This paper briefly introduces the oil monitoring technology - The basic principle and method of particle counter contamination test for equipment condition based maintenance , It also introduces the high-end electronic chips to help upgrade the traditional oil particle monitoring and the work practice of ZHONGTE metrology and testing institute in this regard .

key word : Hydraulic equipment , Oil monitoring , Troubleshooting , Condition based maintenance

l Preface

In hydraulic equipment , The wear of mechanical parts is one of the important reasons for their failure . The wear of hydraulic oil and mechanical parts is closely related , The deterioration and pollution of hydraulic oil will lead to the wear of hydraulic components . In order to find ways and measures to solve the friction and wear problems of hydraulic equipment parts , It is necessary to monitor, analyze and diagnose the lubrication and wear status of hydraulic equipment in operation , Mainly through the analysis of physical and chemical performance indexes of hydraulic oil for equipment and wear metal particles and pollution products in oil , Get the information about the lubrication and wear state of the friction pair of the equipment , Find the hidden trouble of lubrication and wear of hydraulic equipment in time , Guide the lubrication management and condition based maintenance of hydraulic equipment , To ensure the safe operation of hydraulic equipment .

2 Influence of hydraulic oil on hydraulic equipment failure

filter 、 Hydraulic pump 、 Hydraulic motor 、 Hydraulic cylinder 、 The performance failure of various hydraulic components such as control valves is related to their own design and manufacturing quality 、 Operation and maintenance 、 Relevant mechanical and electrical components, etc , It is also related to the performance deterioration and pollution of hydraulic oil , And the proportion of hydraulic equipment failure caused by this is very high . The failure of hydraulic equipment caused by hydraulic oil is invisible 、 Microscopic and gradual , Equipment use and maintenance personnel should correctly understand , And cause enough attention .

2.1 The influence of hydraulic oil performance on hydraulic equipment failure

Hydraulic oil in the hydraulic system in addition to the transmission of kinetic energy as a working medium , It also plays a role in the lubrication of various hydraulic components 、 antiwear 、 antirust 、 Anti corrosion and other functions . There are many physical and chemical performance quality indexes of hydraulic oil , surface 1 The influence of the change of some main performance indexes on the failure of hydraulic equipment is listed .

2.2 Influence of pollutants in hydraulic oil on hydraulic equipment failure

The pollutants in hydraulic oil mainly come from two aspects , One is from outside the hydraulic equipment , Oil products are in production 、 Dust entered during storage and transportation 、 Additives, precipitates, etc : Hydraulic components are in production 、 Casting sand entered during processing and assembly 、 Machining chips 、 Welding slag 、 Cotton yarn fiber, etc : Pollutants entering the surrounding environment during the use of hydraulic equipment , Like water 、 Dust etc. . The second is the wear products produced in the working process of hydraulic equipment , Such as metal wear particles 、 Sealing rubber wear particles, etc : Sludge pollutants generated by oxidation of hydraulic oil during use 、 Paint peeling off inside the equipment .

When these pollutants enter the hydraulic pump a The clearance of motor friction pair , It will aggravate the wear of the friction pair , Shorten the service life of pumps and motors , If it is serious, the friction pair will be stuck , Cause pump and motor failure , Even the whole pump and motor will be scrapped .

Pollutants will aggravate the wear of the piston and cylinder block in the hydraulic cylinder , Increase the leakage of hydraulic oil , Reduce the thrust of hydraulic cylinder : If it is serious, it will jam the piston and piston rod , Stop the hydraulic cylinder , Affect the work of the entire hydraulic system .

Pollutants will aggravate the wear of the moving friction pair of the hydraulic valve , Increase the fit clearance between the valve core and the valve sleeve , Reduce the performance of the hydraulic valve : In serious cases, the hydraulic valve will be stuck , Work failure : Especially for servo valves with high pollution requirements , Contamination will completely disable the servo valve .

Contaminated particles can clog the filter , Cause the pump to empty , Produce vibration and noise , Produce cavitation , Cause a variety of faults .

3 Oil monitoring and fault diagnosis of hydraulic equipment

3.1 The basic principle and method of oil monitoring technology

Oil monitoring technology is based on the analysis of physical and chemical performance indexes of lubricating oil for equipment and wear metal particles and pollution products in oil , Get the information about the lubrication and wear state of the friction pair of the equipment , A technique for diagnosing the lubrication state and wear failure of equipment . In hydraulic equipment ,, Through the comprehensive analysis of the lubrication and wear state information of the friction pairs of these equipment , And refer to the operating conditions of the equipment 、 Equipment friction pair materials 、 Maintenance records of equipment on site , It can effectively realize its wear fault diagnosis , Point out where the equipment fault occurs 、 Determine the type of fault 、 Explain the cause of the failure 、 Predict the time when the fault occurs , Therefore, oil monitoring technology has become an important technical means of fault diagnosis of hydraulic system of mechanical equipment at home and abroad .

Oil monitoring technology is composed of a variety of oil analysis methods , Mainly physical and chemical analysis 、 Spectral analysis 、 Ferrographic analysis 、 Infrared analysis and pollution analysis . surface 2 The main methods of oil technology monitoring are listed 、 Principle and purpose . These analysis methods have their own advantages , It is necessary to select a reasonable analysis method for specific monitoring objects . In the daily oil monitoring work, we should according to the characteristics and operating conditions of the hydraulic equipment of our respective enterprises , Determine reasonable oil monitoring items 、 Sampling points 、 Sampling method and sampling period . In addition, the key of oil diagnosis is the analysis results obtained according to various analysis methods , Comprehensively diagnose the lubrication and wear faults of the equipment , According to the table 1 The influence of the physical and chemical properties of hydraulic oil on the failure of hydraulic equipment is introduced , Put forward reasonable maintenance suggestions according to the situation .

Focus on pollution analysis

Oil monitoring - Particle counter

Monitoring principle : When the particles in the liquid pass through a narrow detection area , Incident light perpendicular to the flow direction of the liquid , Blocked by insoluble particles , Thus, the output signal of the sensor changes , This signal change is proportional to the cross-sectional area of particles , The light blocking method is based on this principle to check the insoluble particles in the injection . High end electronic chips help upgrade the traditional oil particle monitoring sensor to the seventh generation dual laser narrow light detector .

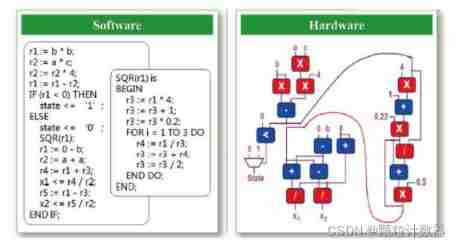

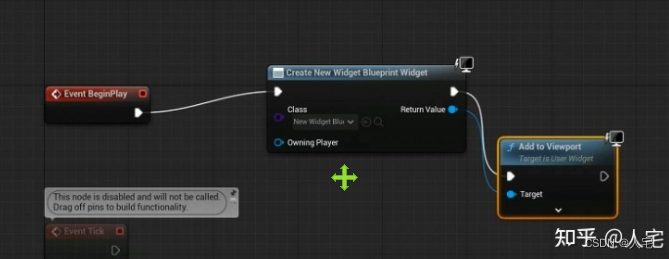

In such an architecture , Software can be infinite , For example, write a circular statement , It can go on and on , But no matter how much hardware is, there are boundaries , This requires the software to be moved to the hardware in blocks and executed in sequence . In the process of moving like this , The hardware architecture on the right is actually changing , We call it that architecture and function can be dynamically changed in real time according to software requirements .

Instrument performance :

Portable particle counter can measure the particle size of oil 、 Monitoring and analysis of cleanliness and pollutants ; Hydraulic equipment and its daily maintenance ; Wear test of hydraulic components ; Test of insoluble particles in pure solution and ultra pure water . Particle counter , Oil particle size analyzer , Oil pollutant analyzer , Hydraulic oil contaminant detector , Oil analysis , Oil monitoring , Particle size analysis of lubricating oil ! Oil particle size tester 、 Hydraulic oil contaminant detector , Laser hydraulic oil particle size detector Oil contamination detector Oil pollution detector .

Detailed instructions

Portable particle counter can measure the particle size of oil 、 Monitoring and analysis of cleanliness and pollutants ; Hydraulic equipment and its daily maintenance ; Wear test of hydraulic components ; Test of insoluble particles in pure solution and ultra pure water . Particle size counter , Oil particle size analyzer , Oil pollutant analyzer , Hydraulic oil contaminant detector , Oil analysis , Oil monitoring , Particle size analysis of lubricating oil ! Oil particle size tester 、 Hydraulic oil contaminant detector -PLD-0203 Laser hydraulic oil particle size detector Oil contamination detector Oil pollution detector .

Advantages of portable particle counter

Jane about - Plody quotes advocating environmental protection 、 Reduce energy consumption 、 Outstanding design style . End beautiful - Plody's economic and practical technical products in China .

fine Dian - Plody's masterpiece of the seventh generation particle detection technology .

Online advantages

Oil filter 、 Cleaning machine 、 Steam turbine unit 、 transformer 、 Electric drive system 、 Lubrication system 、 Test bench, etc , Any unattended site , It's still running equipment , Continuous monitoring and timely data are needed , All are PLD Classic applications of online particle analysis systems , And it is an important part of the production line . An integrated structure ,RS232 And analog signal output , Satisfy DCS And the requirements of field instrument display . On-line 、 real time 、 Continuous sampling 、 Alarm prompt , Be able to grasp and analyze the dynamic pollution diagnosis and wear trend of the hydraulic system in real time . LCD display , Membrane key operation , The result is ISO4406 or NAS1638 Wait for the standard display . Economical, practical and low cost , Small, light and easy to install , Strong anti-interference 、 High temperature and high pressure resistance 、 The shell is strong 、 It can be used in harsh environment .

Offline advantage

Meet the defects of laboratory desktop non removable test , Whether you are mobile measurement or laboratory measurement , Will provide you with a perfect test plan , Make your test more convenient . Solve the production process problem of continuous tracking and monitoring , Whether you are real-time measurement or filter tracking monitoring , Will provide you with a perfect test plan , Make your test faster .

The perfect combination of offline sampling cabin , It can realize the detection of all kinds of oil with large and small viscosity , Optimized detection scheme and evaluation , It can meet the standard test evaluation and custom design detection . Application software platform , Load the mainstream detection methods and evaluation standards at home and abroad , Realize the seamless connection of international standardized testing .

Product introduction

This instrument can measure the particle size of oil 、 Monitoring and analysis of cleanliness and pollutants ; Hydraulic equipment and its daily maintenance ; Wear test of hydraulic components ; Test of insoluble particles in pure solution and ultra pure water . This instrument adopts British plody Technology —“ Photoresist measurement particles ", And adopt the classic method of oil industry NAS1638 and ISO4406, And according to the requirements of users , Built in users need a variety of Standards . Classic seventh generation application software platform , cleaning 、 testing 、 Calibration and calibration of each module can realize convenient setting and operation , Built in threshold 、 Particle size curve and pulse resistance , You can set the particle size value of any channel . Microcomputer color display , Built in operating system and micro printer , It can be tested and printed directly without external computers and printers . With standard serial RS232 mouth , The test results can be stored by an external computer , Convenient data classification 、 retrieval .

May press GB/T18854-2002(ISO11171-1999、JJG066-95) And other standards 、 calibration . Particle size measurement and testing stations can be provided for a fee according to customer requirements “ China Aviation Industry particle size measurement and testing station " Validation report . Provide calibration substances (GBW), Assist customers in the calibration and measurement work once a year . Provide industry “OIL17 Service star " Contracted services ,365 Tianwuyou use . The key recommended products of pler new century Laboratory !

边栏推荐

- [untitled]

- 剑指 Offer 56 数组中数字出现的次数(异或)

- 611. Number of effective triangles

- I can't stand the common annotations of idea anymore

- Idea push project to code cloud

- Using C language to realize IIC driver in STM32 development

- What is Bezier curve? How to draw third-order Bezier curve with canvas?

- Let me teach you how to develop a graphic editor

- A series of problems in offline installation of automated test environment (ride)

- Shadowless cloud desktop - online computer

猜你喜欢

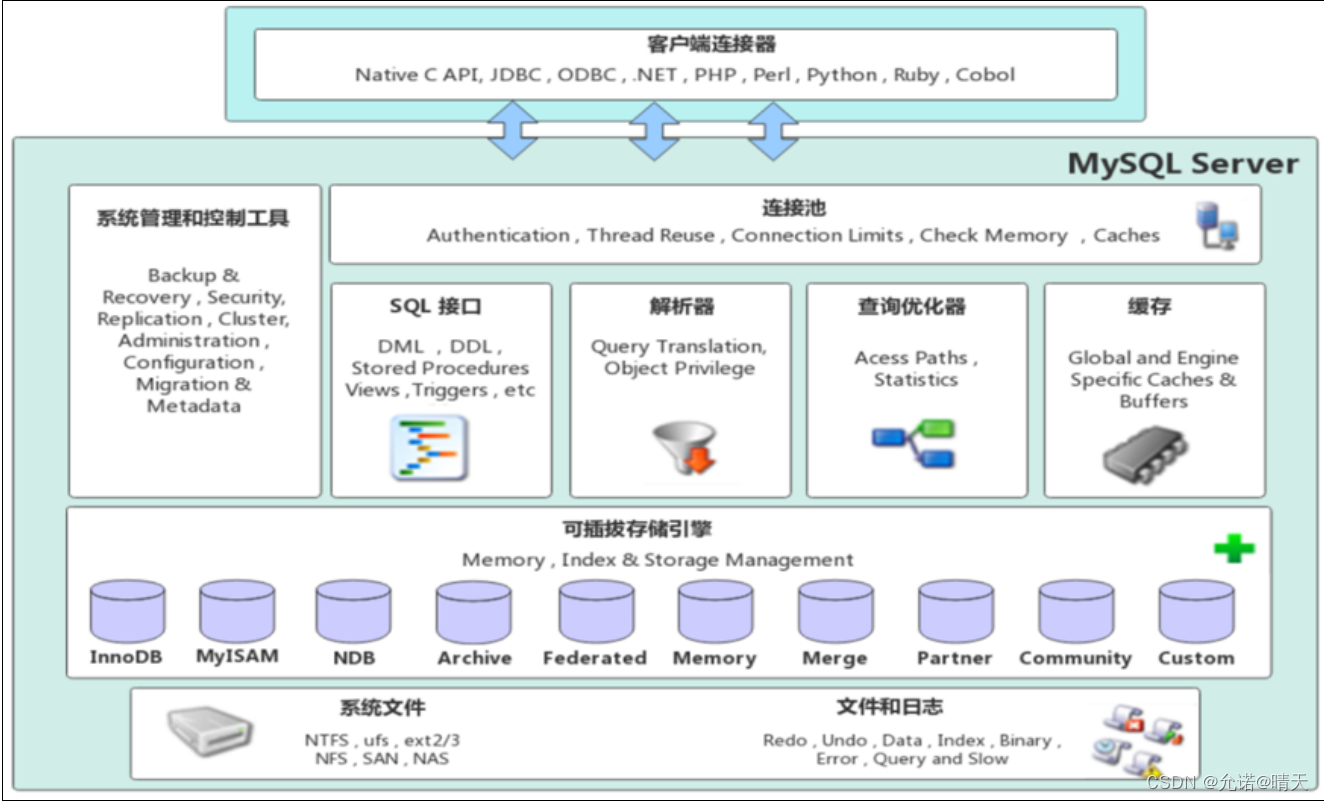

MySql——存储引擎

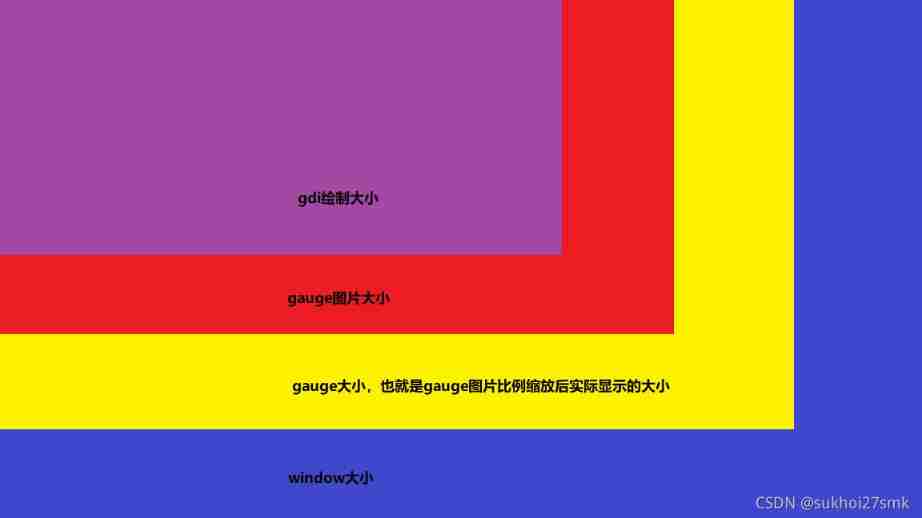

P3D gauge size problem

Ugnx12.0 initialization crash, initialization error (-15)

Oracle triggers and packages

Line test -- data analysis -- FB -- teacher Gao Zhao

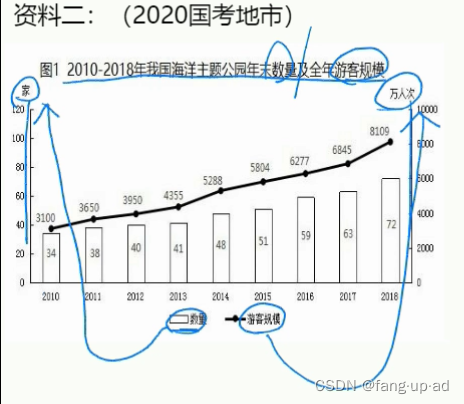

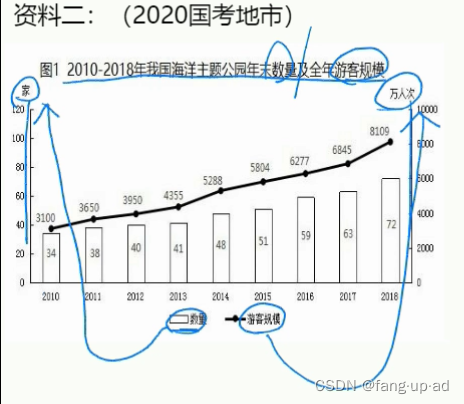

行测--资料分析--fb--高照老师

Ue5 hot update - remote server automatic download and version detection (simplehotupdate)

Thunderbird tutorial \ easy to use mail client

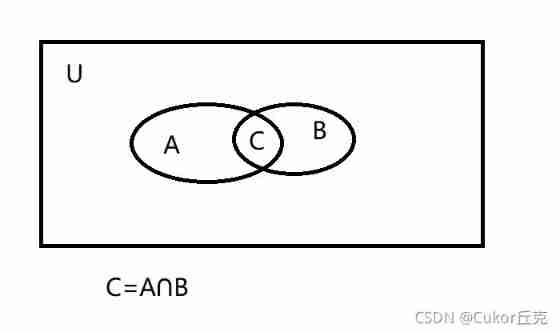

Set theory of Discrete Mathematics (I)

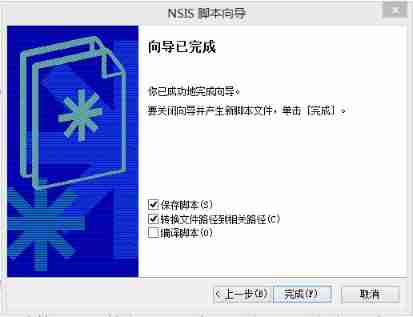

II Simple NSIS installation package

随机推荐

Set theory of Discrete Mathematics (I)

Pagoda create multiple sites with one server

TCP and UDP

Cookie operation

Differences between pycharm and idle and process -- join() in vs Code

611. 有效三角形的个数

使用go语言读取txt文件写入excel中

Miracast技术详解(一):Wi-Fi Display

assert_ Usage of param function

Calibre garbled

大学生活的自我总结-大一

Exit of pyGame, idle and pycharm

Esmini longspeedaction modification

deepin 20 kivy unable to get a window, abort

公安专业知识--哔哩桐老师

arcgis_ spatialjoin

Build your own random wallpaper API for free

P3D gauge size problem

数字孪生实际应用案例-风机篇

What is Bezier curve? How to draw third-order Bezier curve with canvas?