当前位置:网站首页>[disassembly] a visual air fryer. By the way, analyze the internal circuit

[disassembly] a visual air fryer. By the way, analyze the internal circuit

2022-07-06 03:57:00 【Chip home】

With the rise of healthy eating , Declare that there is no need for oil , One click can be used to fry chicken nuggets 、 The air fryer, which can make French fries and bake, has become a small appliance favored by foodies . A friend bought a leen a few years ago (Liven) Second generation air fryer (LR-KZ880 type , Light wave heating tube ,10 Increase volume ), It is said that it is seldom used , Recent failures , Pressing the control panel key does not work . The maintenance personnel told me that the circuit board was broken , It costs hundreds of Yuan . Friends are not willing to send the store for repair , It's a pity to lose it , Please let me have a look , Can a dead horse be a living horse doctor , If the repair is difficult, throw it away .

Generally speaking, the oven uses the radiant heat emitted by electric heating elements to bake food , We can bake food according to different needs , The temperature of the electric oven can generally be 50-250℃ Range adjustment , Used to make roast chicken 、 Roasted Duck 、 Bake bread .

And the air fryer is essentially an oven , Just one more fan than the oven , The working principle is to use a fan to blow heat to food , Use the hot air generated by air circulation , Separate food fat , It can make the food taste closer to fried .

therefore , Simply put , The air fryer borrows the hot air function of the high-end oven , Let the oven make a more delicious kind .

A friend bought a leen a few years ago (Liven) Second generation air fryer (LR-KZ880 type , Light wave heating tube ,10 Increase volume ), It is said that it is seldom used , Recent failures , Pressing the control panel key does not work .

The maintenance personnel told me that the circuit board was broken , It costs hundreds of Yuan . Friends are not willing to send the store for repair , It's a pity to lose it , Please let me have a look , Can a dead horse be a living horse doctor , If the repair is difficult, throw it away .

One 、 appearance

It seems that the number of use is really not much , The color is very new :

After power on , There are indications , But press the buttons on the control panel , There was no response , It's kind of like “ Downtime ”:

The back of the machine , There is a power socket :

Nameplate marks :220V,1200W,10 Liter volume , model LR-KZ880, Light wave tube heat source .

Bottom , There are six silicone foot pads , Put it on the table to prevent sliding :

Pull up the flap handle , Open the transparent cover , It can be baked in food :

Take out the non stick pan with double-layer structure ( The outer layer is heat-resistant plastic , The inner layer is a Teflon coated metal basin , Also known as oil dripping bucket , Pick up the oil dripping from the baked food ):

On the column , There are shaft holes that drive the grill to rotate . On the base , There are testing pans ( Drip bucket ) Whether the microswitch is placed in place :

In the transparent cover ( Flip over ) Inner top , There is a heating system :

Two 、 Disassembly and structure

Hold the transparent cover ( When it is tight , It is recommended to use both hands ), Carefully rotate counterclockwise to remove :

Structure of heating system : Outside is a metal protective net cover , There are light wave heating pipes and fans inside .

Remove a fixing screw at the bottom of the metal protective net :

Remove the protective net :

Inside are annular light wave heating tubes and metal fan impellers . Because this fryer is a closed type , Lampblack has certain deposition on the inner wall and lamp tube :

This is a 1200W Light wave tube , In fact, it is a circular halogen lamp :

Between the leads of the light wave tube is a negative temperature coefficient resistance of metal armor ( Room temperature 27℃, resistance 93.8KΩ), As a temperature sensor :

Now that it's opened , Do hygiene together . First brush with strong kitchen oil cleaner :

Then wipe it with a rag :

Much cleaner :

Remove the three fixing screws of the metal cover of the heater , Remove the cover :

After removing the cover , There is an insulated space behind the aluminum plate of the heater :

Look at it this way , A coaxial fan impeller is installed in the heat insulation space , Blow the heat out , Avoid burning the flip handle , At the same time, it also plays the role of airflow and heat dissipation for the circuit board in the flip handle :

Remove the eight fixing screws on the flip handle :

Remove the round cover plate at the rotating shaft :

Then remove the fixing screws at both ends :

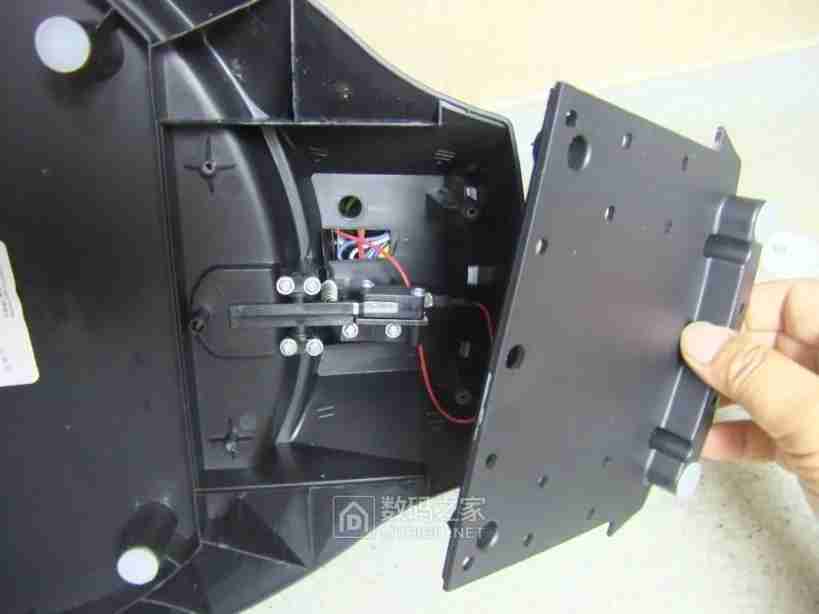

Remove all fixing screws , To separate the flap handle , See the internal circuit board :

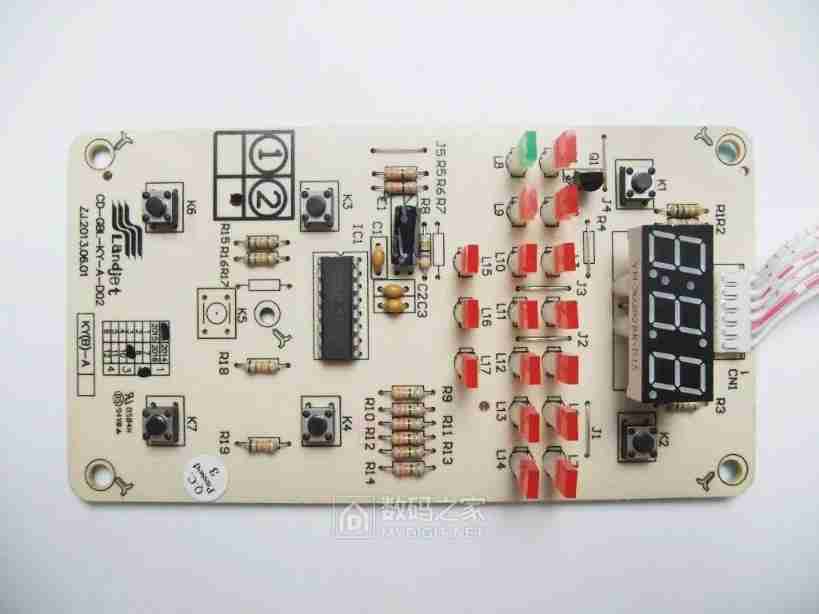

The control circuit board installed on the upper cover of the flip handle :

Fan motor and main circuit board installed in flip handle :

Microswitch at the rotating shaft ( When opening and closing the flip handle , Contacts open or close ):

Remove the cover plate at the back of the column

The internal claw pole permanent magnet synchronous motor is the driving force for the rotation of the grill :

There is a photoelectric switch on the shaft of the motor , Its signal is used to control the continuous rotation or single-sided rotation of the grill :

Remove the base cover 4 A set screw :

See a microswitch inside :

This microswitch is used to detect non stick pans ( Drip bucket ) For placement :

3、 ... and 、 Circuit elements

The fan motor adopts single-phase shaded pole motor ,220V、4W、 speed 2200r/min

Next to the fan motor , There is a temperature fuse fixed on the iron plate , When the circuit has temperature control failure , Play the role of finally cutting off the circuit . This temperature insurance position is narrow , Not easy to replace , The temperature value is unknown :

Remove the fixing screws of the main circuit board , Remove the main circuit board :

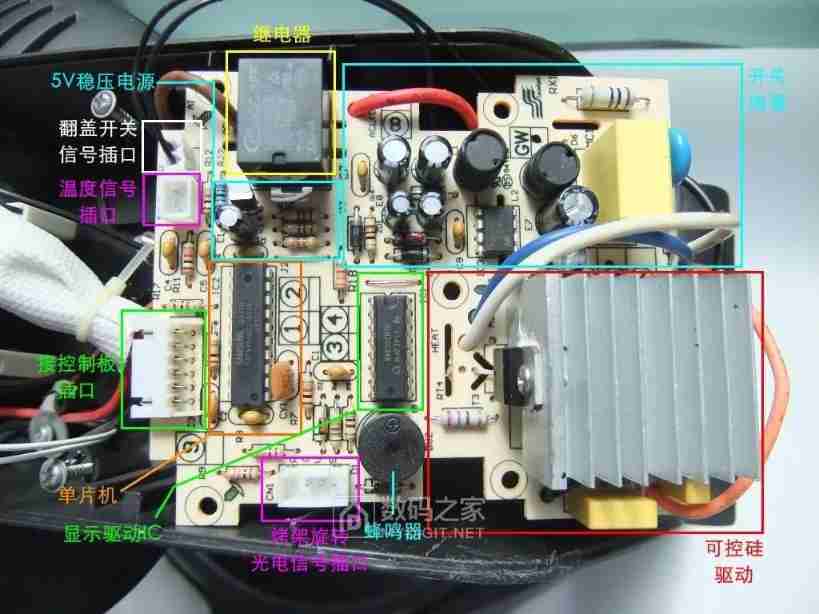

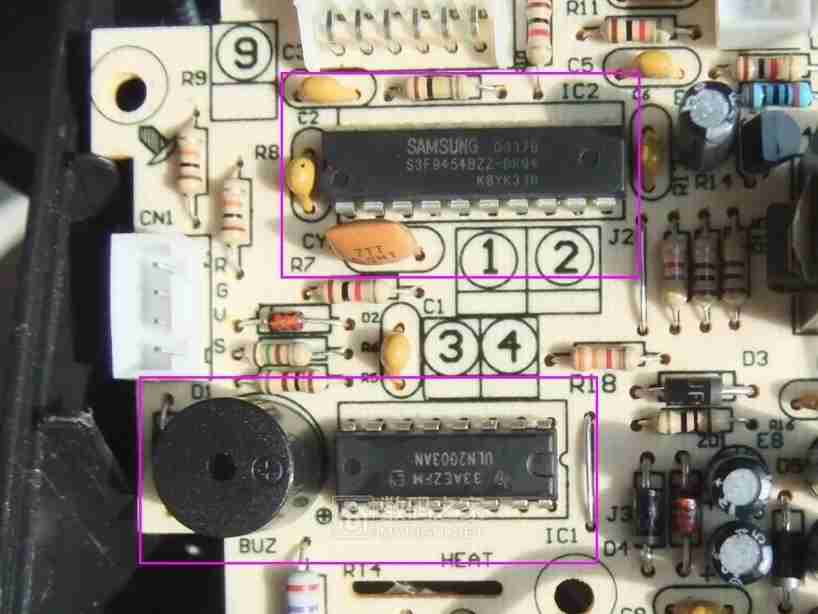

Distribution of component function areas on the main circuit board :

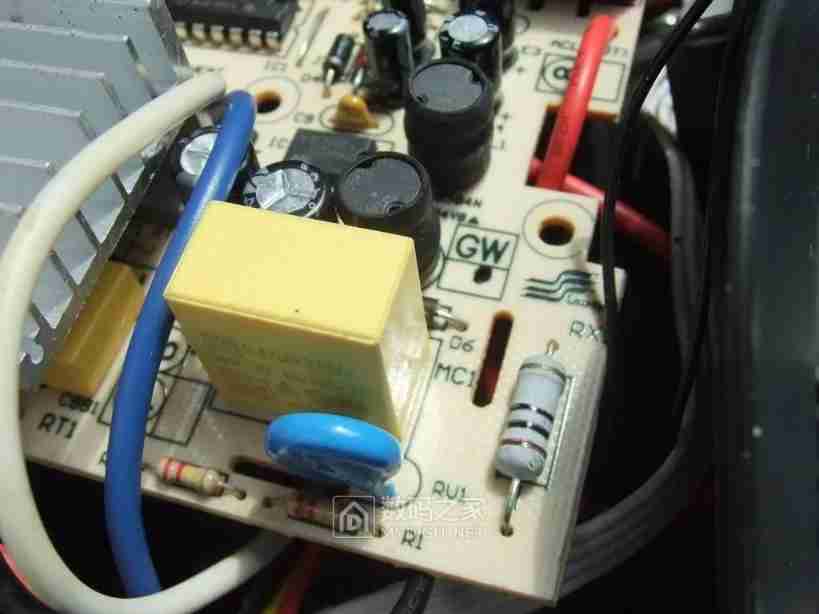

On the circuit board ,RX1 yes 10Ω 2W Safety resistor , Blue disc RV1 It's a varistor , yellow MC1 It's a safety capacitor :

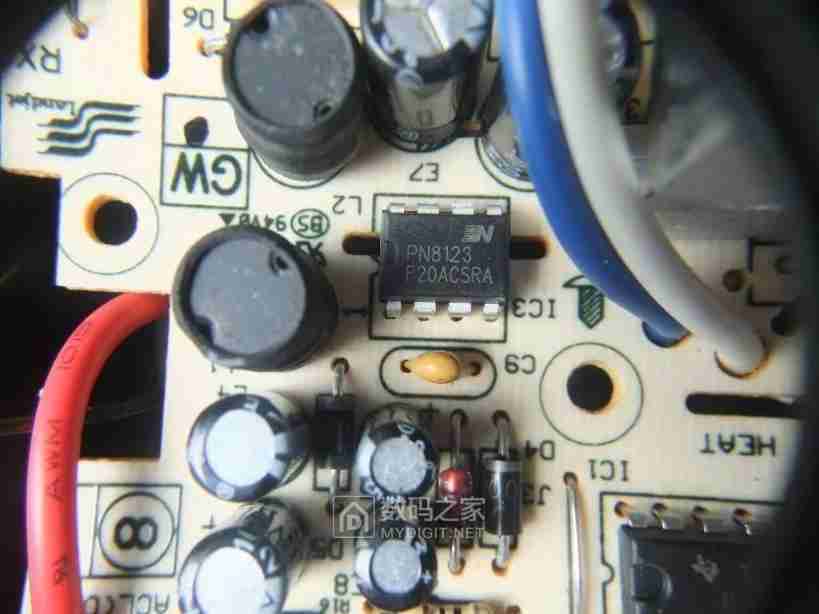

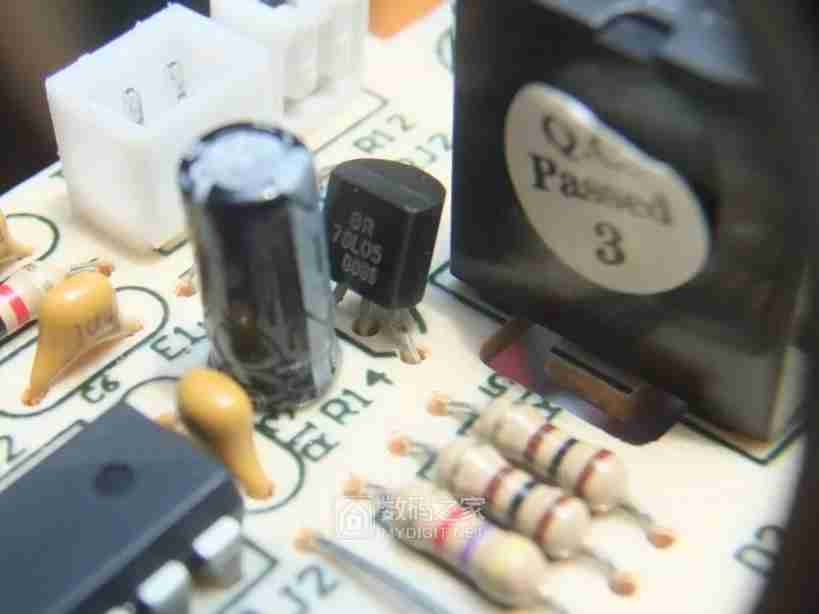

IC3 It is a non isolated power management chip commonly used in small household appliances PN8123:

IC4 yes 78L05, Three terminal linear regulator , Provide 5V regulated power supply :

IC2 It is a commonly used single chip microcomputer for household appliances , model S3F9454BZZ-DK94, Lower Yellow component CY1 It's tripod 8MHz Ceramic filters ;IC1 It is a high current drive array integrated circuit ULN2003AN, It is mostly used for single chip microcomputer 、 Smart meters 、PLC、 Digital output card and other control circuits , The output can reach 500mA/50V, It can directly drive loads such as relays , Next to the black cylinder BUZ It's a buzzer .

12V DC relay , model JQC-3FF, Contact load 10A 277VAC, Open the flip handle 、 Closed time , Be responsible for cutting off or connecting the light wave heating tube 、 Fan 、 Power supply of grill rotating motor :

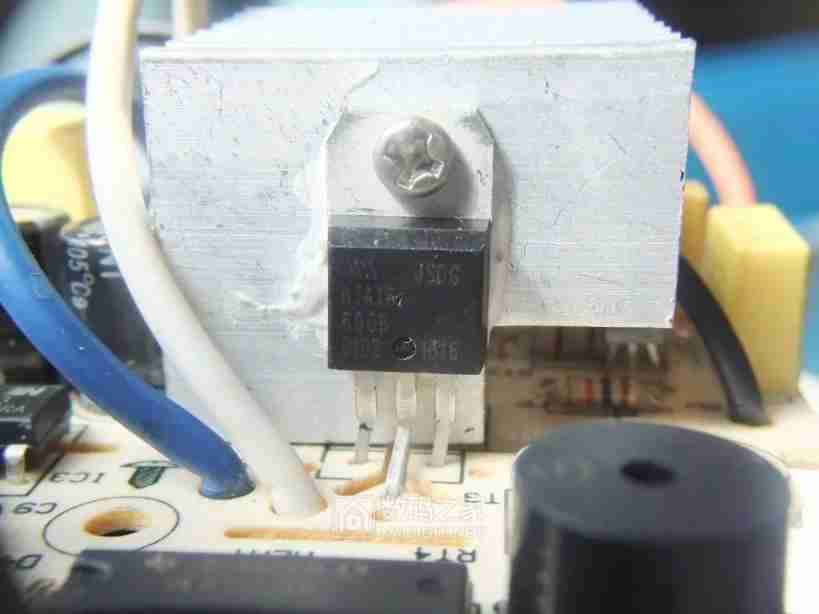

Below is for 1200W The light wave heating tube provides the driven bidirectional thyristor , model BTA16-600B(16A/600V). Due to the high working current , High calorific value , Aluminum radiator has a large volume :

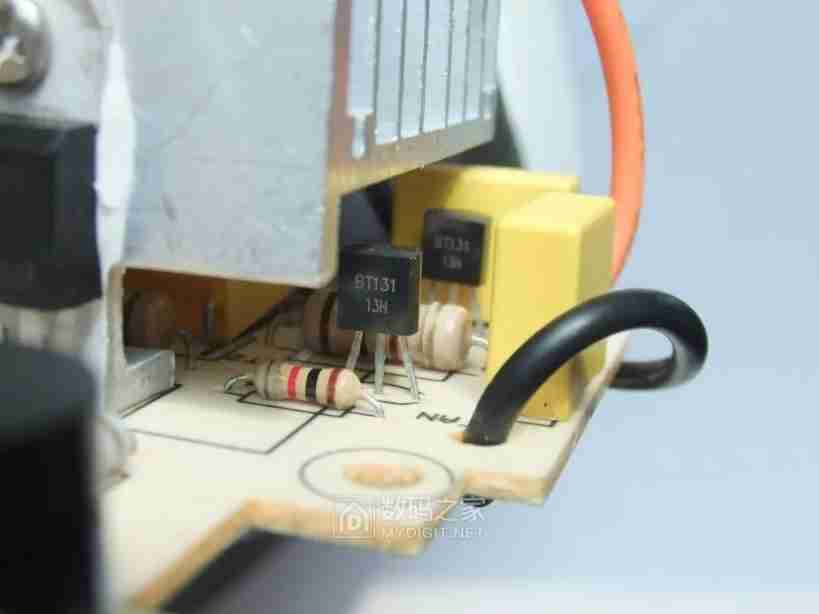

Next to the radiator , There are two small power bidirectional thyristors , model BT31(1A/600V ), They are fans 、 Drive of grill rotating motor :

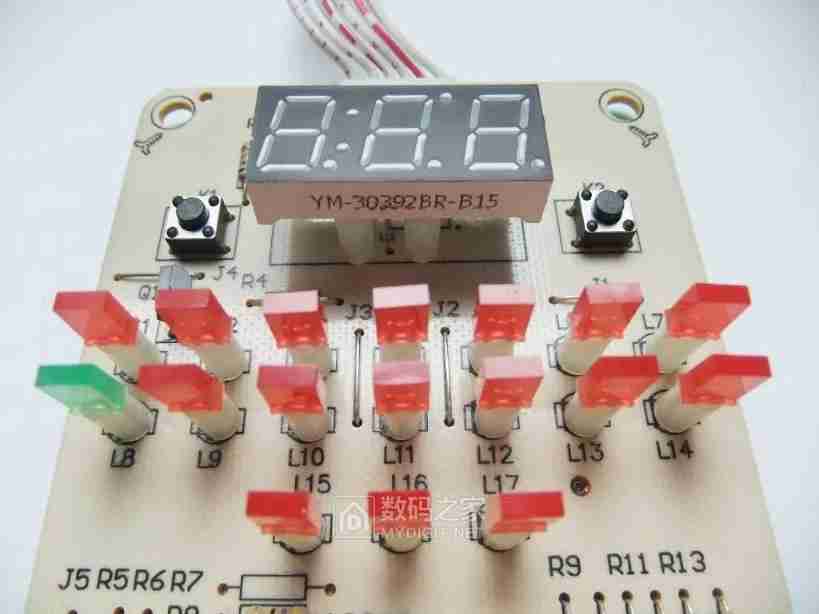

The control circuit board removed from the handle :

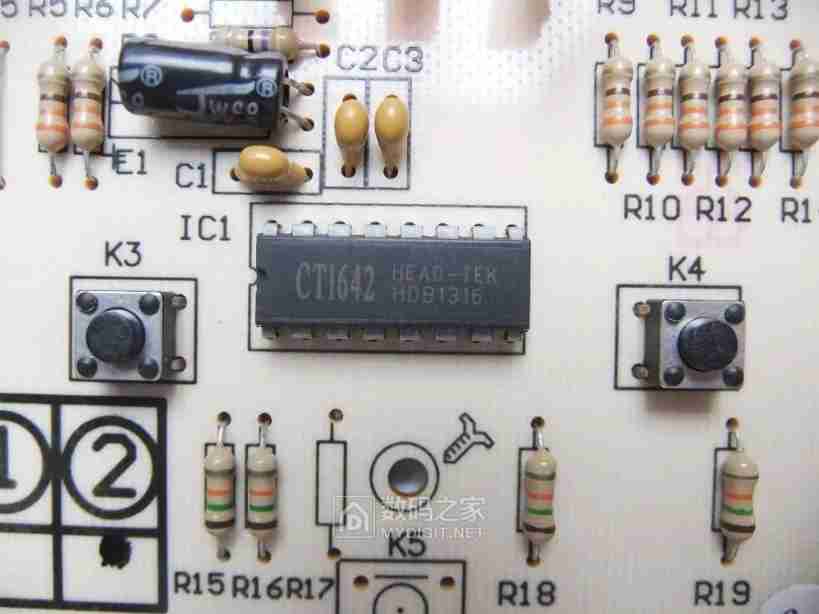

On the circuit board IC1 yes LED Nixie tube drive control integrated circuit , model CT1642:

There are three on the circuit board LED(L1、L9、L12) suffer Q1(9014) drive , rest LED suffer CT1642 drive :

Four 、 Circuit working principle and circuit diagram

1、 Circuit principle

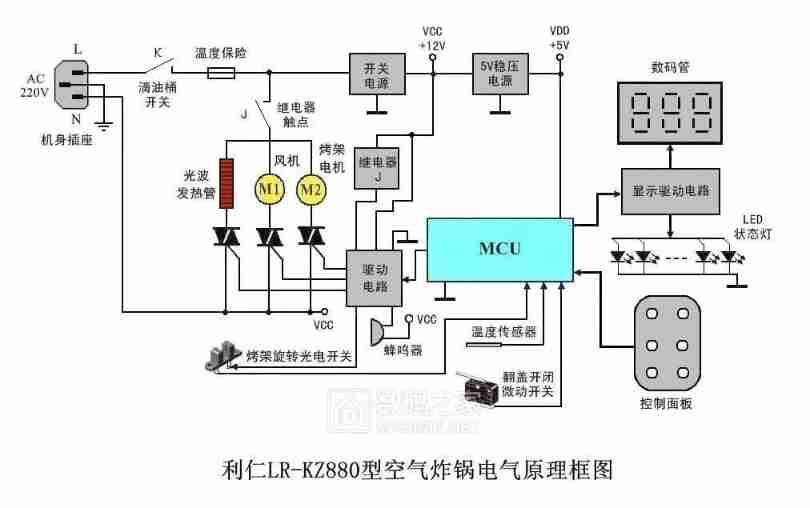

According to the circuit board , Draw the circuit principle block diagram of the air fryer as follows :

How the circuit works :

Plug in the power supply , Only when dripping oil bucket ( Pan ) The position is normal , Its microswitch K Connect ,12V Switching power supply and 5V Regulated power supply can work , Power on the control system . Program self-test , When temperature 、 The position of the flip handle is normal , The buzzer emits a long “ drop ” A sound , Turn on the relay J, The nixie tube shows “000”, Get ready to start the machine . then , Set the baking program on the control panel , Press down “ start-up ” Key , The machine starts to work . During baking , When the temperature reaches the set value , The single chip microcomputer will send the command to stop the heating of the light wave tube ; When the temperature is lower than the set value , The single chip microcomputer sends out the heating command of the light wave tube , Continue alternating , Until the end of time . In the middle of baking , To open the flip , Brush the baked food with oil , You can directly lift the flip handle , The microswitch at the handle rotating shaft is disconnected , After the SCM gets the disconnection signal , Send the command to disconnect the relay , Light wave heating tube 、 Fan 、 The grill rotating motor will stop running immediately , When the flap is restored , Resume the original procedure and continue baking . In circuit , Nixie tube display time , Red LED Display the set baking mode , green LED It's a work indicator . The temperature insurance is used when the machine has a fault exceeding the maximum temperature limit or a serious short circuit fault , Cut off the power supply of the whole machine , To be sent for repair and troubleshooting 、 The normal operation can be resumed only after the temperature insurance is replaced .

2、 Circuit diagram

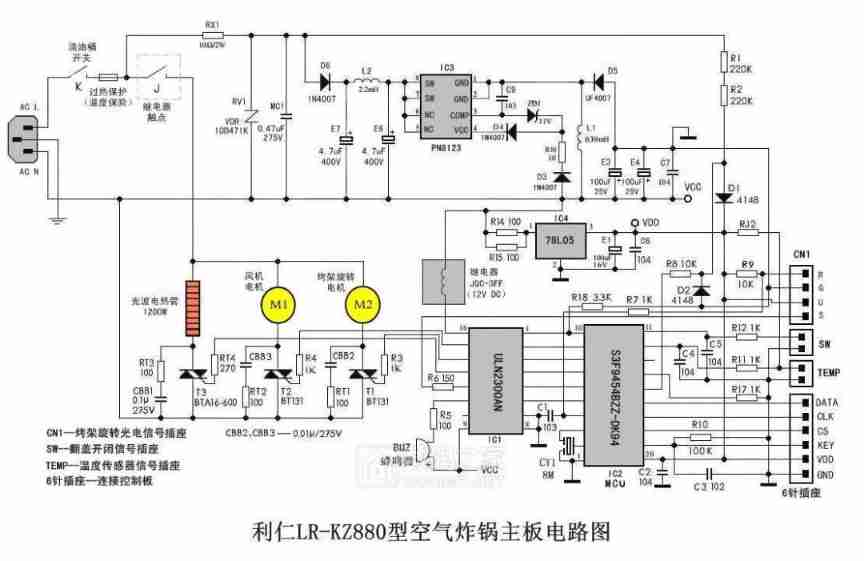

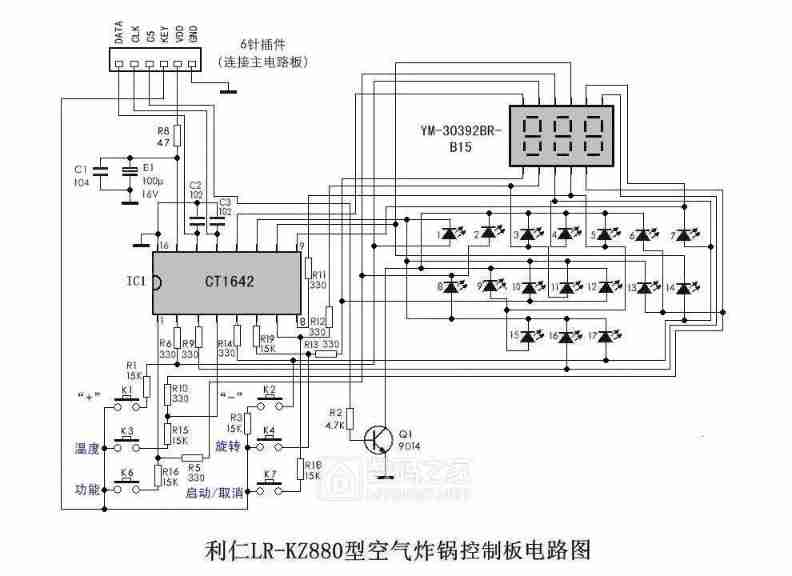

Compare with the real object , Draw the circuit diagram as follows . Respectively, the circuit diagram of the main circuit board 、 Control board circuit diagram . The parameters of each element are marked on the circuit diagram . There may be imperfections , For your reference during maintenance .

⑴ The circuit diagram of the circuit board is as follows :

⑵ The circuit diagram of the control board is as follows :

5、 ... and 、 Eliminate the problem that the control panel is not responding

1、 Failure cause analysis and inspection

The functions of panel keys are shown in the figure below :

Analyze with the circuit diagram . Under normal circumstances , The machine is powered on , Pass self-test , Only press first “ function ” key , After selecting the baking program , Then press the “ start-up ” key , The machine can start to work . Panel keys are not responding , First check “ function ” Is there a problem with the key !

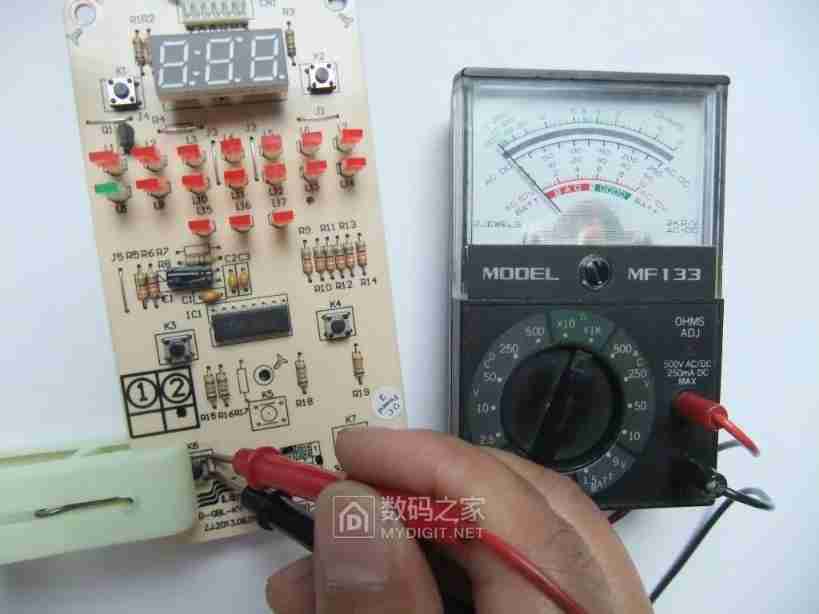

On the control circuit board ,“ function ” The fretting number of the key is K6. Use a multimeter to detect , Press down , no , There is a problem ! There is no problem with other inching :

2、 Repair faulty components

Drop anhydrous alcohol into K6 Fretting gap , Press the key repeatedly ( The circuit board must also be erected , Let the liquid inside the fretting flow downward ), The purpose is to clean the contact surface inside the fretting :

After the alcohol volatilizes , Then use the table to detect , Press down , Through the ! For the sake of security , Deal with the rest of the fretting .

Restore the machine installation , Power on the machine , Panel keys respond , The fault phenomenon is eliminated :

The baking mode is set , Press down “ start-up ” Key , The machine works normally . however , The light is strong , It looks a little dazzling :

6、 ... and 、 Conclusion

1、 The essence of the air fryer is an electric oven with internal hot air circulation . Force out the oil inside the food by heating and baking ( Some food must be painted separately ), Form a state of being scorched outside and tender inside , Need to fully master machine characteristics and food processing skills , To make delicious food . Practice makes perfect , Just practice more . For light wave tube heating , Although intuitive , I think light loss and light pollution are also existing problems .

2、 Micro button failure is a common problem of this kind of small household appliances . The main reason is that domestic manufacturers face fierce competition in the market , To control production costs , Do not hesitate to lower the standard of quality control , The result is that the product is not durable . During maintenance , Can go straight to key electronic components , Replace after testing .

( This article comes from digital home , author :goodanytime , The copyright belongs to the author ,)

边栏推荐

- [American competition] mathematical terms

- Basic concepts of LTE user experience

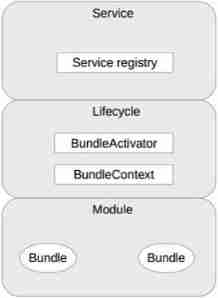

- Microkernel structure understanding

- 简易博客系统

- MySQL 中的数据类型介绍

- Cf464e the classic problem [shortest path, chairman tree]

- math_ Derivative function derivation of limit & differential & derivative & derivative / logarithmic function (derivative definition limit method) / derivative formula derivation of exponential functi

- Error 1045 (28000): access denied for user 'root' @ 'localhost' (using password: no/yes

- Mathematical modeling regression analysis relationship between variables

- 简述C语言中的符号和链接库

猜你喜欢

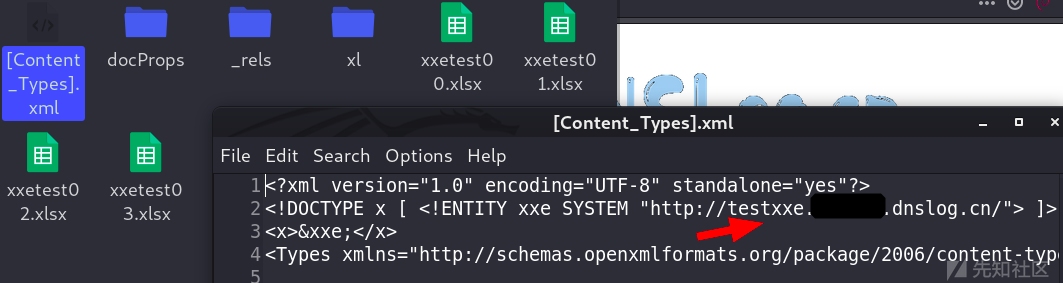

记一次excel XXE漏洞

WPF effect Article 191 box selection listbox

Microkernel structure understanding

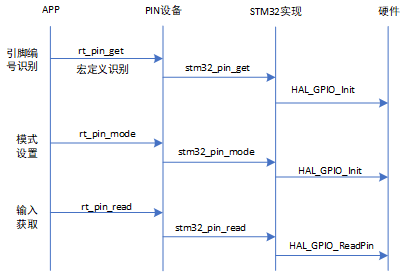

2.2 STM32 GPIO operation

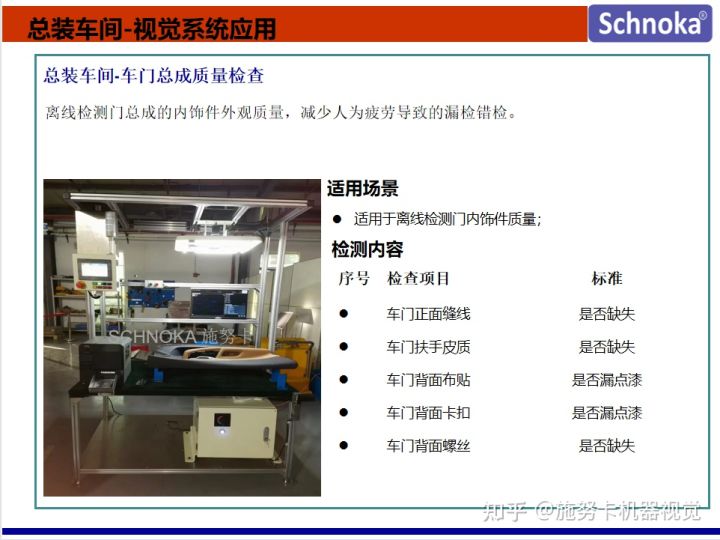

Schnuka: 3D vision detection application industry machine vision 3D detection

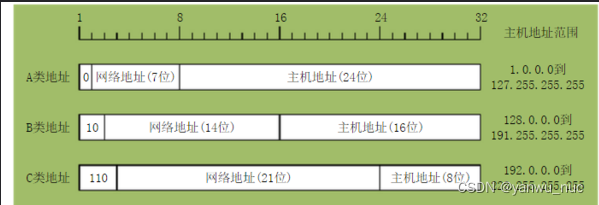

Ipv4中的A 、B、C类网络及子网掩码

Stc8h development (XII): I2C drive AT24C08, at24c32 series EEPROM storage

Blue style mall website footer code

2.13 weekly report

![[analysis of variance] single factor analysis and multi factor analysis](/img/92/5337d0ef6e487d1af2f56cb3a3268a.jpg)

[analysis of variance] single factor analysis and multi factor analysis

随机推荐

Flask learning and project practice 9: WTF form verification

Thread sleep, thread sleep application scenarios

DM8 backup set deletion

BUAA magpie nesting

《2022年中国银行业RPA供应商实力矩阵分析》研究报告正式启动

51nod 1130 n factorial length V2 (Stirling approximation)

3.2 detailed explanation of rtthread serial port device (V2)

P7735-[noi2021] heavy and heavy edges [tree chain dissection, line segment tree]

Overview of super-resolution reconstruction of remote sensing images

/usr/bin/gzip: 1: ELF: not found/usr/bin/gzip: 3: : not found/usr/bin/gzip: 4: Syntax error:

Security xxE vulnerability recurrence (XXe Lab)

[practice] mathematics in lottery

80% of the diseases are caused by bad living habits. There are eight common bad habits, which are both physical and mental

Schnuka: visual positioning system working principle of visual positioning system

Quick sort function in C language -- qsort

[FPGA tutorial case 12] design and implementation of complex multiplier based on vivado core

[practical exercise] face location model based on skin color

有条件地 [JsonIgnore]

Ybtoj coloring plan [tree chain dissection, segment tree, tarjan]

Tips for using dm8huge table