当前位置:网站首页>Schnuka: visual positioning system working principle of visual positioning system

Schnuka: visual positioning system working principle of visual positioning system

2022-07-06 03:26:00 【Schnuka machine vision】

Robot vision and positioning are widely used in the field of industrial guidance . For industrial robots working on automated production lines , The most completed operations are ” Grab — place “ action , In order to do this , It is necessary to obtain the positioning information of the operated object , First, the robot must know the position of the object before it is operated , The second is to know the target position after the object is operated , To ensure that the robot can complete the task accurately .

In most industrial robot applications , Robots only operate according to fixed procedures , The initial position and end position of the object are predetermined , For high quality work , The production line is required to be relatively fixed , High positioning accuracy , As a result, production flexibility is reduced , The cost increases greatly , At this time, the flexibility of the production line and product quality are contradictory .

In the project of manipulator application , The core is the visual guidance and positioning system , It mainly includes dynamic and general positioning 、 Precise positioning and assembly 、 Precise position adjustment and other technologies , With the development of economy and the improvement of people's living standards , The logistics industry has made great progress, and there is an urgent demand for automation application .

Schnuka (SCHNOKA) Founded on 2010 year , Successively in Shanghai , Suzhou and Wuhan have set up branches . National high tech enterprise , Committed to building a high-tech company with the strongest brain control for intelligent production lines and smart factories . The company revolves around perception & Identify core technologies to build intelligent equipment , Based on robot vision algorithm and single robot workstation 、 Multi robot group integration 、 Industry customized application . Build product systems , For intelligent production line 、 Smart logistics and other scenarios realize software defined intelligence .

SCHNOKA ( Schnuka ) stay 3D Machine vision algorithm 、 Robot flexible control 、 Hand eye collaborative fusion 、 Production line level robot collaboration 、 Plant level intelligent planning and scheduling are applied by leading technologies and industries , In the automotive industry, intelligent sorting production line 、 Large size and high precision three-dimensional measurement 、 He has rich project experience in intelligent sorting of large scene logistics handling robots .

SCHNOKA( Schnuka ) A number of core products of the automotive industry benchmarking production line 、 Lithium new energy lighthouse factory 、 Smart factory of construction machinery 、 Smart logistics and other fields are applied in multiple scenarios . Has cooperated with Baiya international 、 Sound health care 、 Middon group 、 Vida paper 、 faw-vw 、 Shanghai Volkswagen 、 Volvo cars 、 Chery Jaguar Land Rover 、 Geely 、 Changan automobile 、 SAIC GM Wuling 、 Great Wall honeycomb new energy 、 Sany heavy industry 、 AVIC Shenfei 、 China Tunnel Group 、 Siemens high voltage switch 、 China medium car 、ABB( China ) And other well-known enterprises at home and abroad have established good partnership , Won wide praise from head customers .

边栏推荐

- Python implementation of maddpg - (1) openai maddpg environment configuration

- SAP ALV颜色代码对应颜色(整理)

- 暑期刷题-Day3

- MADDPG的pythorch实现——(1)OpenAI MADDPG环境配置

- 【SLAM】lidar-camera外参标定(港大MarsLab)无需二维码标定板

- pytorch加载数据

- Advanced learning of MySQL -- Fundamentals -- isolation level of transactions

- Lua uses require to load the shared library successfully, but the return is Boolean (always true)

- svg拖动点裁剪图片js特效

- 【Rust 笔记】18-宏

猜你喜欢

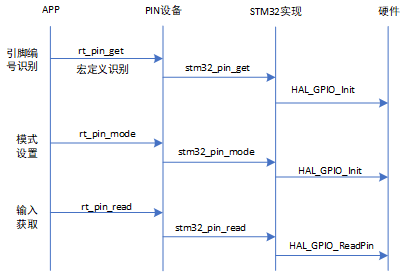

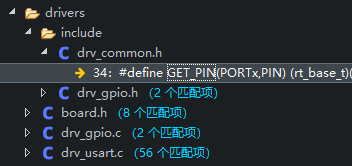

2.2 STM32 GPIO operation

Map sorts according to the key value (ascending plus descending)

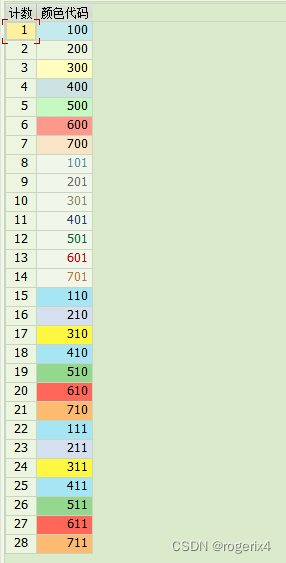

SAP ALV颜色代码对应颜色(整理)

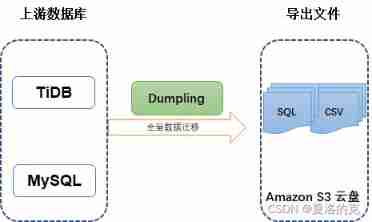

Tidb ecological tools (backup, migration, import / export) collation

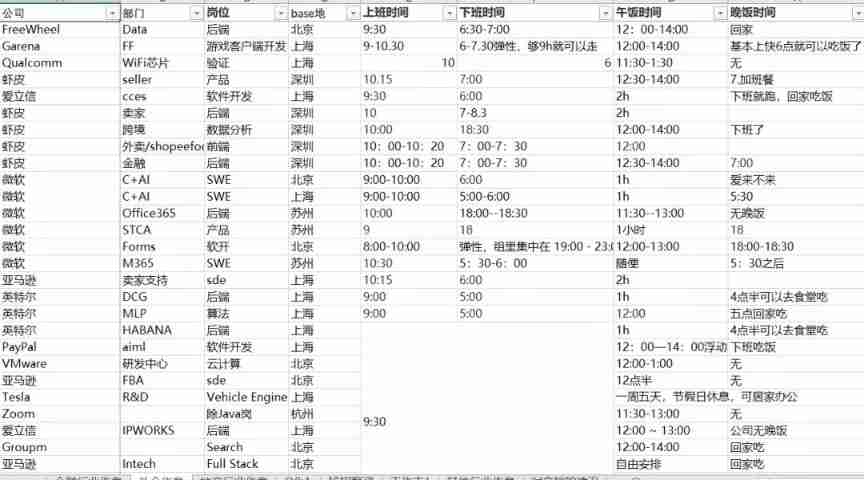

Crazy, thousands of netizens are exploding the company's salary

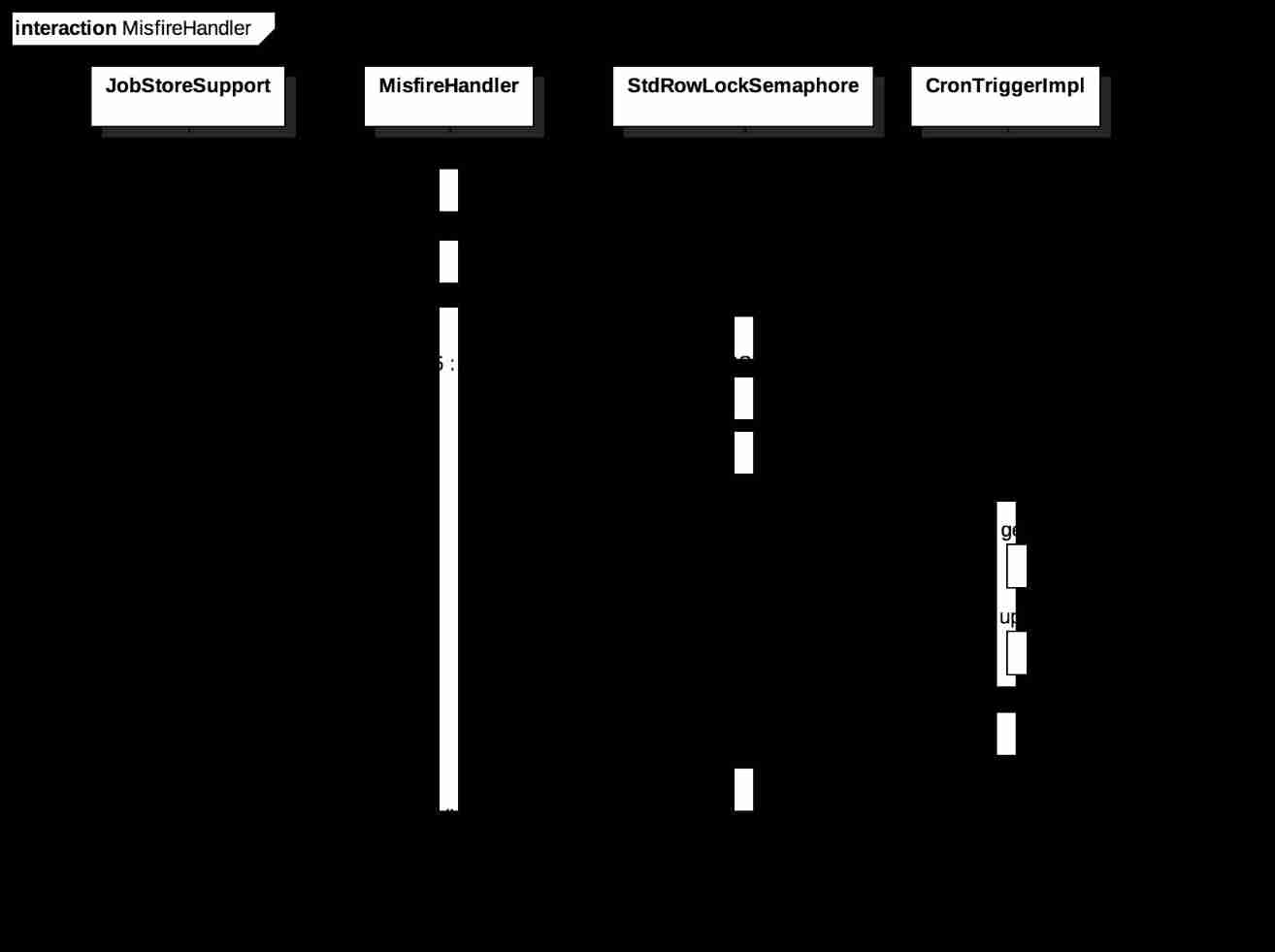

Quartz misfire missed and compensated execution

Pointer written test questions ~ approaching Dachang

2.1 rtthread pin设备详解

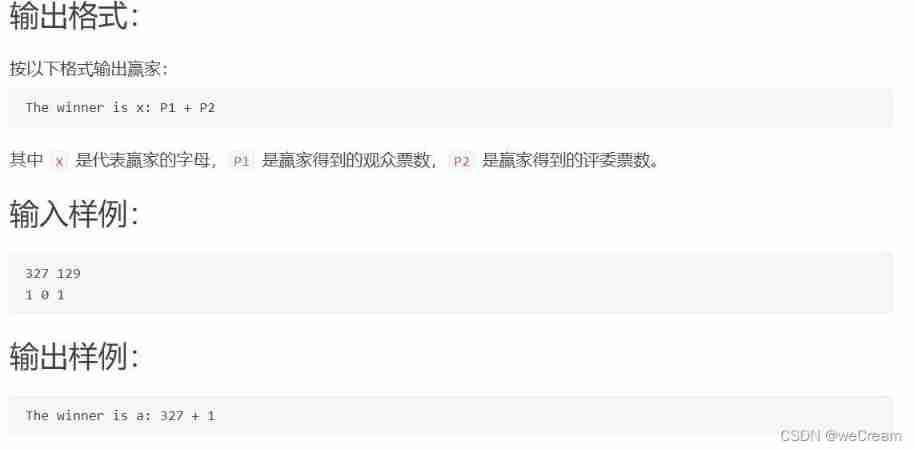

Who is the winner of PTA

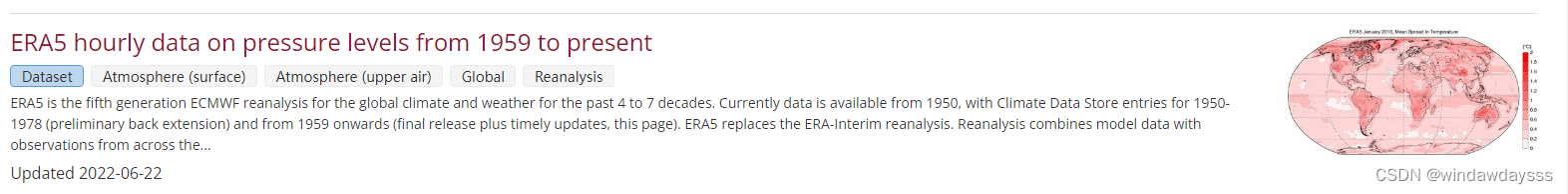

Era5 reanalysis data download strategy

随机推荐

Performance analysis of user login TPS low and CPU full

Mysql database operation

2.2 STM32 GPIO operation

Redis SDS principle

BUAA喜鹊筑巢

2022工作中遇到的问题四

11. Container with the most water

Remote Sensing Image Super-resolution and Object Detection: Benchmark and State of the Art

2.2 fonctionnement stm32 GPIO

Item 10: Prefer scoped enums to unscoped enums.

Esbuild & SWC: a new generation of construction tools

给新人工程师组员的建议

Tomb. Weekly update of Finance (February 7 - February 13)

Audio-AudioRecord Binder通信机制

Shell pass parameters

The solution of permission denied (750 permissions should be used with caution)

Record the process of reverse task manager

js凡客banner轮播图js特效

出现Permission denied的解决办法(750权限谨慎使用)

Introduction to DeNO