当前位置:网站首页>【STM32】实战3.1—用STM32与TB6600驱动器驱动42步进电机(一)

【STM32】实战3.1—用STM32与TB6600驱动器驱动42步进电机(一)

2022-07-07 08:41:00 【咕咕与瓜】

目录

0 参考资料出处

参考博客:

1、利用STM32F103精确控制步进电机_jl_mlh的博客-CSDN博客_stm32控制步进电机;

2、图文介绍步进电机的满步、半步、微步驱动原理-深圳东么川伺服控制有限公司;

3、【STM32】stm32驱动TB6600控制42/57步进电机的案例(TIM中断和PWM实验)_创客协会的阿蛋°的博客-CSDN博客_stm32驱动42步进电机程序;

4、STM32之TIM定时器驱动42步进电机-驱动器型号TB6600_为丽力的博客-CSDN博客_stm32驱动42步进电机;

参考论文:

1、侯艳霞. 混合式步进电机工作原理及其PLC控制;

1 实验预期效果

完成步进电机的正转(不通过串口控制、非可移动供电)。

2 硬件学习

2.1 TB6600驱动器

某宝店家提供资料如下:

2.1.1 通过拨码开关设定细分与电流

2.1.2 共阴共阳接线法

共阴:

驱动器 —— stm32

DIR- 与 PUL- —— GND

DIR+ —— 方向引脚

PUL+ —— 脉冲引脚共阳:

驱动器 —— stm32

DIR+ 与 PUL+ —— +5V

DIR- —— 方向引脚

PUL- —— 脉冲引脚

2.2 开关电源(AC转DC变压器)& 电源线

2.3 42步进电机

2.3.1 基本知识

由商家提供资料可知:42步进电机的相数为2(A、B两相,每相并联支路数为2,每条支路串联2个线圈)、步距角为1.8°(满步时)、转子齿数为50。

每拍只有一相绕组通电,四拍构成一个循环。上图中,定子的B相通电,磁极2的5个齿与转子齿对齿(如下图4),由分析可知,磁极6也同转子齿对齿,而磁极4和8是齿对槽(如下图2)。旁边的A相绕组的磁极3的5个齿和转子齿有1/4齿距的错位(如下图3),即1.8°(360°/50/4)。

当B相断电A相通电时,磁极3产生N极性,吸合离它最近的S极转子齿,使得转子沿顺时针方向转过1.8°,实现磁极3和转子齿对齿,此时磁极4和转子齿有1/4齿距的错位。

依次类推若继续按四拍的顺序通电,转子就按顺时针方向一步一步地转动,每通电一次(即每来一个脉冲)转子转过1.8°,即称步距角为1.8°,转子转过一圈需要360°/1.8° =200个脉冲。与表相符。

【参数及公式可参阅文章:利用STM32F103精确控制步进电机_jl_mlh的博客-CSDN博客】

① 拍数(N=km)——每一次循环所包含的通电状态数(电机转过一个齿距角所需脉冲数);

单拍制(k=1)——拍数 = 相数;双拍制(k=2)——拍数 = 相数的两倍;② 相数(m)——即电机内部的线圈组数。如果使用细分驱动器,则相数将变得没有意义,只需在驱动器上改变细分数,就可以改变步距角;

③ 转子齿数(Zr);

④ 步距角(θs)——步进机通过一个电脉冲转子转过的角度;

⑤ 转速(n)

2.3.2 转速细分控制

电机的转速与脉冲频率成正比,电机转过的角度与脉冲数成正比。所以控制脉冲数和脉冲频率就可以精确调速。

f:脉冲频率;θs:步距角;X:细分值;n:转速(rad/s)。

若已知步距角=1.8°,细分值=32,想要达到1rad/s的转速(每秒转一圈),则脉冲频率=1*32*360/1.8=6400,即6400个脉冲为一转,与所给表相符合。

2.3.3 满步、半步、微步驱动原理

【该部分摘自文章:图文介绍步进电机的满步、半步、微步驱动原理】

满步驱动(单拍满步驱动和双拍满步驱动 ):

半步驱动:

半步驱动的好处是提高分辨率,但是缺点是扭矩只有满步驱动的70%,当然,也可以通过优化线圈中电流大小,来提高半步驱动扭矩。

微步驱动:

图上英文为:With maximum power in phase A, phase B is at zero. The rotor will line up with phase A. As current to phase A decreases, it increases to phase B. The rotor will take small steps towards phase B until phase B is at its maximum and phase A is at zero. The process then continues around the other phases.

翻译过来大致意思就是:A线圈开始有最大电流,B线圈电流为0,转子指向A线圈。如果A线圈电流慢慢减小,B线圈电流慢慢增大,转子就会慢慢的转向B线圈。

宏观来看,A、B线圈的电流变化都接近于三角函数曲线。电流每一步变化的大小,则决定了微步运动的大小。虽然步数越多,运动越平滑,但是扭矩也会相应的减小。

电流每一步的变化的大小,决定了微步运动的大小,右上图为1/4,1/8,1/16微步电流变化示意图。

微步运动举例:在图1中,A线圈通满电流,图2中A线圈通最大电流的0.92倍,而B线圈通最大电流的0.38倍,实现22.5°旋转。同理,图3中,A和B线圈同时通最大电流的0.71倍,可以实现45°旋转。

步数越多,可以获得越平滑的运动,噪声也越小,不容易失步(丢步),但是代价就是扭矩大大减小。

3 软件配置与硬件接线

3.1 STM32CubeMX的配置

【基础配置见【STM32】1—零基础硬件软件配置 & 完成LED的闪烁_ココの奇妙な冒険的博客-CSDN博客_stm32配置软件】

原理图:

3.1.1 配置定时器TIM2

其输出引脚为PA0。

3.1.2 配置引脚PA1

因希望其正转,则将电平拉高:

3.2 驱动器的接线方式

采用共阴接法:

3.3 细分与电流调节

相关见2.1.1

4 代码编写

【代码参考博客STM32之TIM定时器驱动42步进电机-驱动器型号TB6600_stm32驱动42步进电机】

在自动生成代码的基础上需在main.c中增加:

定义变量:

int count;开启PWM中断并拉高引脚(后者可省去):

HAL_TIM_PWM_Start_IT(&htim2,TIM_CHANNEL_1);

HAL_GPIO_WritePin(DIR_GPIO_Port, DIR_Pin, GPIO_PIN_SET); 计数1000次后停转:

void HAL_TIM_PWM_PulseFinishedCallback(TIM_HandleTypeDef *htim)

{

if(htim == &htim2)

{

if(count <1000)

{

count++;

}

else

{

HAL_TIM_PWM_Stop_IT(&htim2, TIM_CHANNEL_1);

count = 0;

}

}

}

总代码如下:

main.c:

/* USER CODE BEGIN Header */

/**

******************************************************************************

* @file : main.c

* @brief : Main program body

******************************************************************************

* @attention

*

* Copyright (c) 2022 STMicroelectronics.

* All rights reserved.

*

* This software is licensed under terms that can be found in the LICENSE file

* in the root directory of this software component.

* If no LICENSE file comes with this software, it is provided AS-IS.

*

******************************************************************************

*/

/* USER CODE END Header */

/* Includes ------------------------------------------------------------------*/

#include "main.h"

#include "tim.h"

#include "gpio.h"

/* Private includes ----------------------------------------------------------*/

/* USER CODE BEGIN Includes */

int count;

/* USER CODE END Includes */

/* Private typedef -----------------------------------------------------------*/

/* USER CODE BEGIN PTD */

/* USER CODE END PTD */

/* Private define ------------------------------------------------------------*/

/* USER CODE BEGIN PD */

/* USER CODE END PD */

/* Private macro -------------------------------------------------------------*/

/* USER CODE BEGIN PM */

/* USER CODE END PM */

/* Private variables ---------------------------------------------------------*/

/* USER CODE BEGIN PV */

/* USER CODE END PV */

/* Private function prototypes -----------------------------------------------*/

void SystemClock_Config(void);

/* USER CODE BEGIN PFP */

/* USER CODE END PFP */

/* Private user code ---------------------------------------------------------*/

/* USER CODE BEGIN 0 */

/* USER CODE END 0 */

/**

* @brief The application entry point.

* @retval int

*/

int main(void)

{

/* USER CODE BEGIN 1 */

/* USER CODE END 1 */

/* MCU Configuration--------------------------------------------------------*/

/* Reset of all peripherals, Initializes the Flash interface and the Systick. */

HAL_Init();

/* USER CODE BEGIN Init */

/* USER CODE END Init */

/* Configure the system clock */

SystemClock_Config();

/* USER CODE BEGIN SysInit */

/* USER CODE END SysInit */

/* Initialize all configured peripherals */

MX_GPIO_Init();

MX_TIM2_Init();

/* USER CODE BEGIN 2 */

HAL_TIM_PWM_Start_IT(&htim2,TIM_CHANNEL_1);

HAL_GPIO_WritePin(DIR_GPIO_Port, DIR_Pin, GPIO_PIN_SET);

/* USER CODE END 2 */

/* Infinite loop */

/* USER CODE BEGIN WHILE */

while (1)

{

/* USER CODE END WHILE */

/* USER CODE BEGIN 3 */

}

/* USER CODE END 3 */

}

/**

* @brief System Clock Configuration

* @retval None

*/

void SystemClock_Config(void)

{

RCC_OscInitTypeDef RCC_OscInitStruct = {0};

RCC_ClkInitTypeDef RCC_ClkInitStruct = {0};

/** Configure the main internal regulator output voltage

*/

__HAL_RCC_PWR_CLK_ENABLE();

__HAL_PWR_VOLTAGESCALING_CONFIG(PWR_REGULATOR_VOLTAGE_SCALE1);

/** Initializes the RCC Oscillators according to the specified parameters

* in the RCC_OscInitTypeDef structure.

*/

RCC_OscInitStruct.OscillatorType = RCC_OSCILLATORTYPE_HSI;

RCC_OscInitStruct.HSIState = RCC_HSI_ON;

RCC_OscInitStruct.HSICalibrationValue = RCC_HSICALIBRATION_DEFAULT;

RCC_OscInitStruct.PLL.PLLState = RCC_PLL_ON;

RCC_OscInitStruct.PLL.PLLSource = RCC_PLLSOURCE_HSI;

RCC_OscInitStruct.PLL.PLLM = 8;

RCC_OscInitStruct.PLL.PLLN = 168;

RCC_OscInitStruct.PLL.PLLP = RCC_PLLP_DIV2;

RCC_OscInitStruct.PLL.PLLQ = 4;

if (HAL_RCC_OscConfig(&RCC_OscInitStruct) != HAL_OK)

{

Error_Handler();

}

/** Initializes the CPU, AHB and APB buses clocks

*/

RCC_ClkInitStruct.ClockType = RCC_CLOCKTYPE_HCLK|RCC_CLOCKTYPE_SYSCLK

|RCC_CLOCKTYPE_PCLK1|RCC_CLOCKTYPE_PCLK2;

RCC_ClkInitStruct.SYSCLKSource = RCC_SYSCLKSOURCE_PLLCLK;

RCC_ClkInitStruct.AHBCLKDivider = RCC_SYSCLK_DIV1;

RCC_ClkInitStruct.APB1CLKDivider = RCC_HCLK_DIV4;

RCC_ClkInitStruct.APB2CLKDivider = RCC_HCLK_DIV2;

if (HAL_RCC_ClockConfig(&RCC_ClkInitStruct, FLASH_LATENCY_5) != HAL_OK)

{

Error_Handler();

}

}

/* USER CODE BEGIN 4 */

void HAL_TIM_PWM_PulseFinishedCallback(TIM_HandleTypeDef *htim)

{

if(htim == &htim2)

{

if(count <1000)

{

count++;

}

else

{

HAL_TIM_PWM_Stop_IT(&htim2, TIM_CHANNEL_1);

count = 0;

}

}

}

/* USER CODE END 4 */

/**

* @brief This function is executed in case of error occurrence.

* @retval None

*/

void Error_Handler(void)

{

/* USER CODE BEGIN Error_Handler_Debug */

/* User can add his own implementation to report the HAL error return state */

__disable_irq();

while (1)

{

}

/* USER CODE END Error_Handler_Debug */

}

#ifdef USE_FULL_ASSERT

/**

* @brief Reports the name of the source file and the source line number

* where the assert_param error has occurred.

* @param file: pointer to the source file name

* @param line: assert_param error line source number

* @retval None

*/

void assert_failed(uint8_t *file, uint32_t line)

{

/* USER CODE BEGIN 6 */

/* User can add his own implementation to report the file name and line number,

ex: printf("Wrong parameters value: file %s on line %d\r\n", file, line) */

/* USER CODE END 6 */

}

#endif /* USE_FULL_ASSERT */

gpio.c:

/* USER CODE BEGIN Header */

/**

******************************************************************************

* @file gpio.c

* @brief This file provides code for the configuration

* of all used GPIO pins.

******************************************************************************

* @attention

*

* Copyright (c) 2022 STMicroelectronics.

* All rights reserved.

*

* This software is licensed under terms that can be found in the LICENSE file

* in the root directory of this software component.

* If no LICENSE file comes with this software, it is provided AS-IS.

*

******************************************************************************

*/

/* USER CODE END Header */

/* Includes ------------------------------------------------------------------*/

#include "gpio.h"

/* USER CODE BEGIN 0 */

/* USER CODE END 0 */

/*----------------------------------------------------------------------------*/

/* Configure GPIO */

/*----------------------------------------------------------------------------*/

/* USER CODE BEGIN 1 */

/* USER CODE END 1 */

/** Configure pins as

* Analog

* Input

* Output

* EVENT_OUT

* EXTI

*/

void MX_GPIO_Init(void)

{

GPIO_InitTypeDef GPIO_InitStruct = {0};

/* GPIO Ports Clock Enable */

__HAL_RCC_GPIOC_CLK_ENABLE();

__HAL_RCC_GPIOH_CLK_ENABLE();

__HAL_RCC_GPIOA_CLK_ENABLE();

/*Configure GPIO pin Output Level */

HAL_GPIO_WritePin(DIR_GPIO_Port, DIR_Pin, GPIO_PIN_SET);

/*Configure GPIO pin : PtPin */

GPIO_InitStruct.Pin = DIR_Pin;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_PP;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_LOW;

HAL_GPIO_Init(DIR_GPIO_Port, &GPIO_InitStruct);

}

/* USER CODE BEGIN 2 */

/* USER CODE END 2 */

tim.c:

/* USER CODE BEGIN Header */

/**

******************************************************************************

* @file tim.c

* @brief This file provides code for the configuration

* of the TIM instances.

******************************************************************************

* @attention

*

* Copyright (c) 2022 STMicroelectronics.

* All rights reserved.

*

* This software is licensed under terms that can be found in the LICENSE file

* in the root directory of this software component.

* If no LICENSE file comes with this software, it is provided AS-IS.

*

******************************************************************************

*/

/* USER CODE END Header */

/* Includes ------------------------------------------------------------------*/

#include "tim.h"

/* USER CODE BEGIN 0 */

/* USER CODE END 0 */

TIM_HandleTypeDef htim2;

/* TIM2 init function */

void MX_TIM2_Init(void)

{

/* USER CODE BEGIN TIM2_Init 0 */

/* USER CODE END TIM2_Init 0 */

TIM_ClockConfigTypeDef sClockSourceConfig = {0};

TIM_MasterConfigTypeDef sMasterConfig = {0};

TIM_OC_InitTypeDef sConfigOC = {0};

/* USER CODE BEGIN TIM2_Init 1 */

/* USER CODE END TIM2_Init 1 */

htim2.Instance = TIM2;

htim2.Init.Prescaler = 83;

htim2.Init.CounterMode = TIM_COUNTERMODE_UP;

htim2.Init.Period = 999;

htim2.Init.ClockDivision = TIM_CLOCKDIVISION_DIV1;

htim2.Init.AutoReloadPreload = TIM_AUTORELOAD_PRELOAD_ENABLE;

if (HAL_TIM_Base_Init(&htim2) != HAL_OK)

{

Error_Handler();

}

sClockSourceConfig.ClockSource = TIM_CLOCKSOURCE_INTERNAL;

if (HAL_TIM_ConfigClockSource(&htim2, &sClockSourceConfig) != HAL_OK)

{

Error_Handler();

}

if (HAL_TIM_PWM_Init(&htim2) != HAL_OK)

{

Error_Handler();

}

sMasterConfig.MasterOutputTrigger = TIM_TRGO_RESET;

sMasterConfig.MasterSlaveMode = TIM_MASTERSLAVEMODE_DISABLE;

if (HAL_TIMEx_MasterConfigSynchronization(&htim2, &sMasterConfig) != HAL_OK)

{

Error_Handler();

}

sConfigOC.OCMode = TIM_OCMODE_PWM1;

sConfigOC.Pulse = 500;

sConfigOC.OCPolarity = TIM_OCPOLARITY_HIGH;

sConfigOC.OCFastMode = TIM_OCFAST_DISABLE;

if (HAL_TIM_PWM_ConfigChannel(&htim2, &sConfigOC, TIM_CHANNEL_1) != HAL_OK)

{

Error_Handler();

}

/* USER CODE BEGIN TIM2_Init 2 */

/* USER CODE END TIM2_Init 2 */

HAL_TIM_MspPostInit(&htim2);

}

void HAL_TIM_Base_MspInit(TIM_HandleTypeDef* tim_baseHandle)

{

if(tim_baseHandle->Instance==TIM2)

{

/* USER CODE BEGIN TIM2_MspInit 0 */

/* USER CODE END TIM2_MspInit 0 */

/* TIM2 clock enable */

__HAL_RCC_TIM2_CLK_ENABLE();

/* TIM2 interrupt Init */

HAL_NVIC_SetPriority(TIM2_IRQn, 0, 0);

HAL_NVIC_EnableIRQ(TIM2_IRQn);

/* USER CODE BEGIN TIM2_MspInit 1 */

/* USER CODE END TIM2_MspInit 1 */

}

}

void HAL_TIM_MspPostInit(TIM_HandleTypeDef* timHandle)

{

GPIO_InitTypeDef GPIO_InitStruct = {0};

if(timHandle->Instance==TIM2)

{

/* USER CODE BEGIN TIM2_MspPostInit 0 */

/* USER CODE END TIM2_MspPostInit 0 */

__HAL_RCC_GPIOA_CLK_ENABLE();

/**TIM2 GPIO Configuration

PA0-WKUP ------> TIM2_CH1

*/

GPIO_InitStruct.Pin = GPIO_PIN_0;

GPIO_InitStruct.Mode = GPIO_MODE_AF_PP;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_LOW;

GPIO_InitStruct.Alternate = GPIO_AF1_TIM2;

HAL_GPIO_Init(GPIOA, &GPIO_InitStruct);

/* USER CODE BEGIN TIM2_MspPostInit 1 */

/* USER CODE END TIM2_MspPostInit 1 */

}

}

void HAL_TIM_Base_MspDeInit(TIM_HandleTypeDef* tim_baseHandle)

{

if(tim_baseHandle->Instance==TIM2)

{

/* USER CODE BEGIN TIM2_MspDeInit 0 */

/* USER CODE END TIM2_MspDeInit 0 */

/* Peripheral clock disable */

__HAL_RCC_TIM2_CLK_DISABLE();

/* TIM2 interrupt Deinit */

HAL_NVIC_DisableIRQ(TIM2_IRQn);

/* USER CODE BEGIN TIM2_MspDeInit 1 */

/* USER CODE END TIM2_MspDeInit 1 */

}

}

/* USER CODE BEGIN 1 */

/* USER CODE END 1 */

5 最终效果

42步进电机的转动

6 附录

6.1 TB6600驱动器

某宝店家提供资料如下:

6.1.1 驱动器功能

6.1.2 接线

6.1.3 常见故障及对策

6.2 42步进电机尺寸图与内部结构

边栏推荐

- 1323:【例6.5】活动选择

- Summary of router development knowledge

- 一些线上学术报告网站与机器学习视频

- 打算参加安全方面工作,信息安全工程师怎么样,软考考试需要怎么准备?

- 深入分析ERC-4907协议的主要内容,思考此协议对NFT市场流动性意义!

- 1323: [example 6.5] activity selection

- P2788 math 1 - addition and subtraction

- 【作业】2022.7.6 写一个自己的cal函数

- JS implementation chain call

- Leetcode-560: subarray with sum K

猜你喜欢

P2788 数学1(math1)- 加减算式

深入分析ERC-4907协议的主要内容,思考此协议对NFT市场流动性意义!

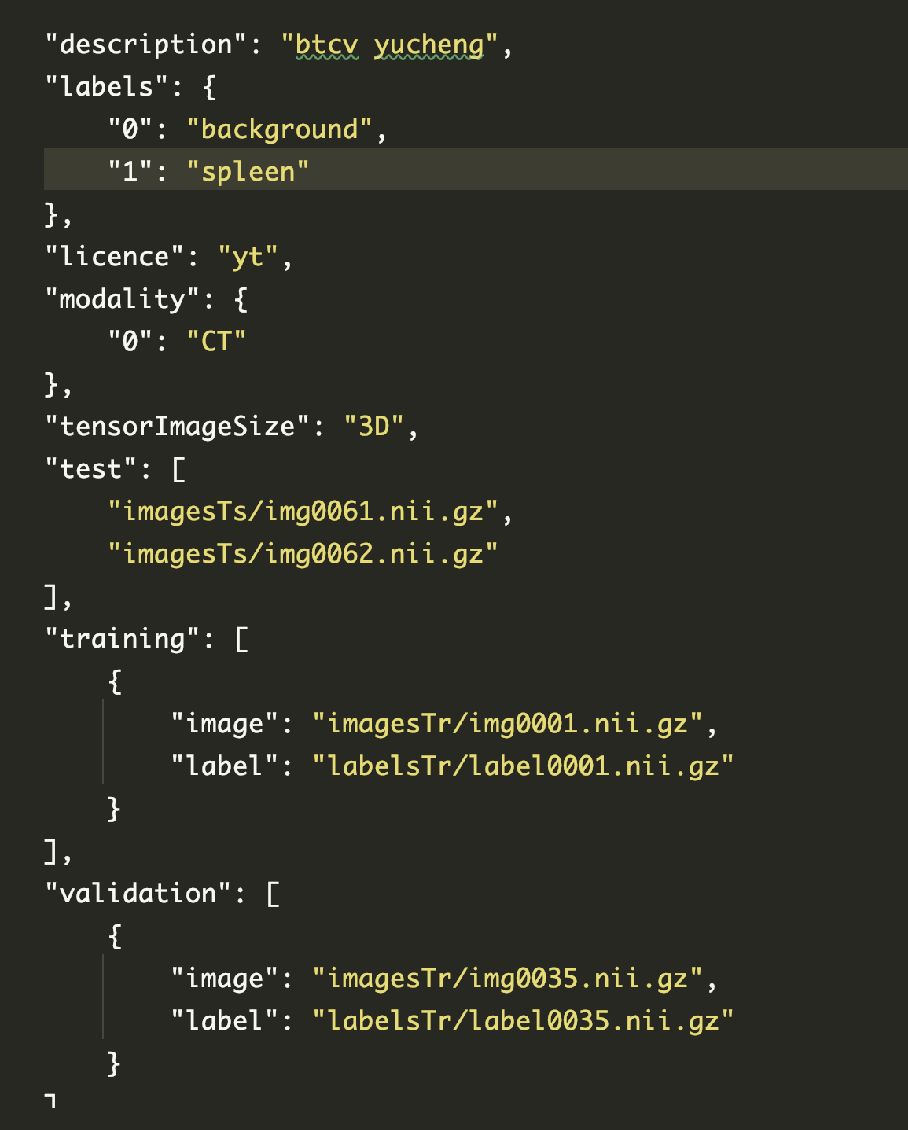

使用 load_decathlon_datalist (MONAI)快速加载JSON数据

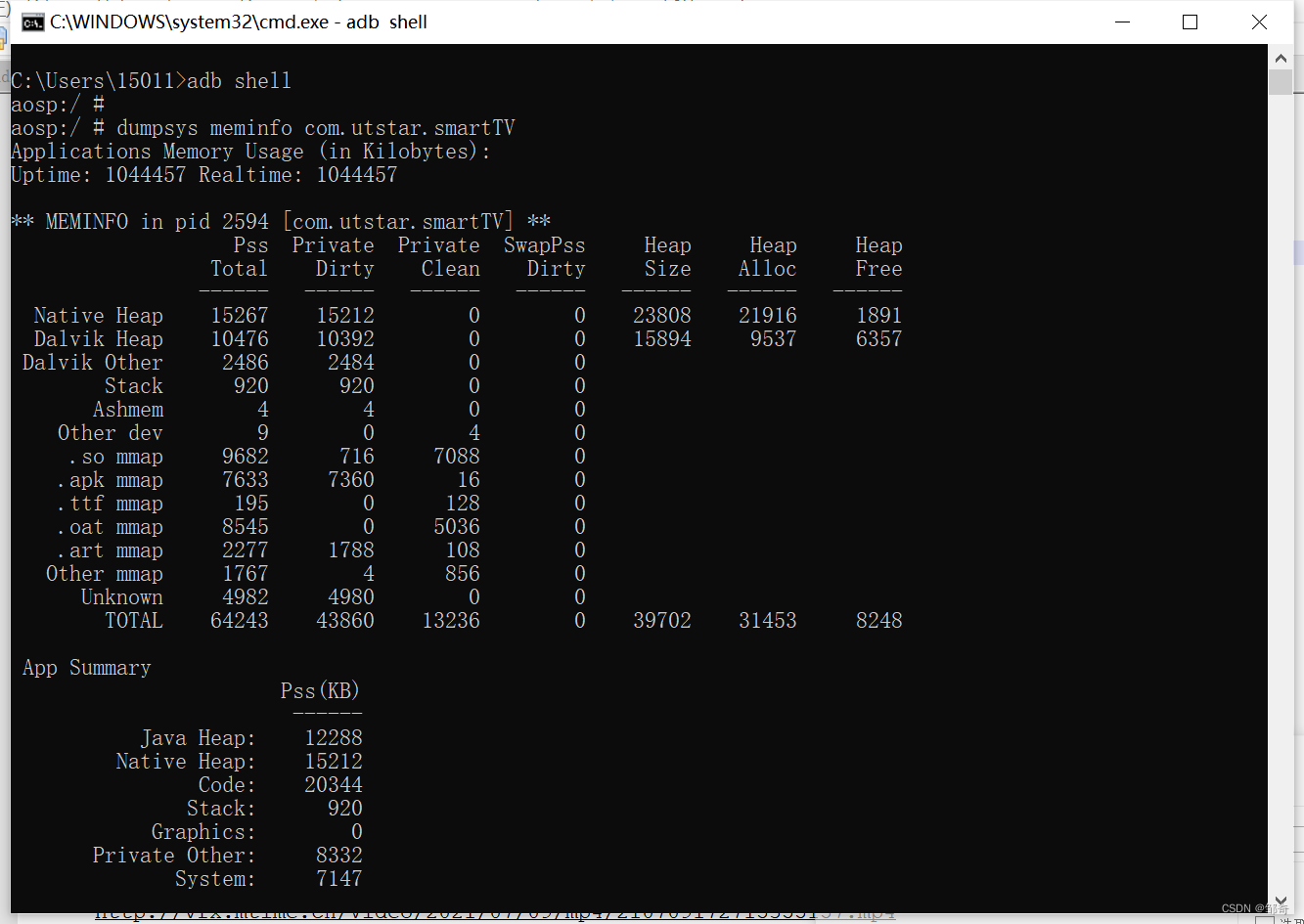

Adb 实用命令(网络包、日志、调优相关)

1321:【例6.3】删数问题(Noip1994)

How much review time does it usually take to take the intermediate soft exam?

Application of OpenGL gllightfv function and related knowledge of light source

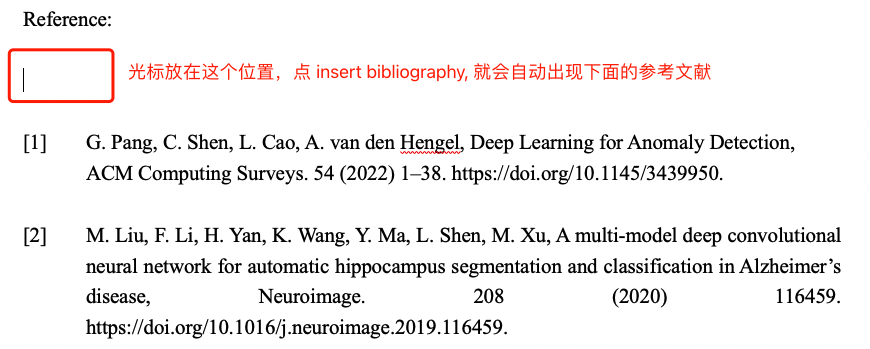

Mendeley -- a free document management tool that automatically inserts references into papers

I plan to take part in security work. How about information security engineers and how to prepare for the soft exam?

OpenGL glLightfv 函数的应用以及光源的相关知识

随机推荐

555电路详解

Typescript interface inheritance

路由器开发知识汇总

Some superficial understanding of word2vec

【推荐系统 01】Rechub

Network engineer test questions and answers in May of the first half of 2022

Mendeley--免费的文献管理工具,给论文自动插入参考文献

Using tansformer to segment three-dimensional abdominal multiple organs -- actual battle of unetr

Unable to open kernel device '\.\vmcidev\vmx': operation completed successfully. Reboot after installing vmware workstation? Module "devicepoweron" failed to start. Failed to start the virtual machine

php \n 换行无法输出

打算参加安全方面工作,信息安全工程师怎么样,软考考试需要怎么准备?

Deeply analyze the main contents of erc-4907 agreement and think about the significance of this agreement to NFT market liquidity!

软考一般什么时候出成绩呢?在线蹬?

MySQL insert data create trigger fill UUID field value

What is an intermediate network engineer? What is the main test and what is the use?

The width of table is 4PX larger than that of tbody

P2788 math 1 - addition and subtraction

枪出惊龙,众“锁”周之

Is the gold content of intermediate e-commerce division in the soft exam high?

ADB utility commands (network package, log, tuning related)