当前位置:网站首页>Four goals for the construction of intelligent safety risk management and control platform for hazardous chemical enterprises in Chemical Industry Park

Four goals for the construction of intelligent safety risk management and control platform for hazardous chemical enterprises in Chemical Industry Park

2022-07-07 07:03:00 【Maidao Technology】

2022 year 1 month 29 Japan , Issued by emergency management department 《 Guidelines for the construction of intelligent safety risk management and control platform in chemical industry parks ( On a trial basis )》 and 《 Guide for the construction of intelligent safety risk management and control platform for hazardous chemical enterprises ( On a trial basis )》, To guide chemical parks and hazardous chemical enterprises to build platforms 、 With the platform , Use advanced technical means such as information and figures to strengthen the ability of safety risk prevention and control , Promote chemical industry park 、 Enterprises carry out digital transformation of safety risk management and control of hazardous chemicals 、 Intelligent upgrade .

Construction objectives

One 、 Support the effective implementation of the dual prevention system

Through digital management means , Help management organizations at all levels effectively prevent and resolve major safety risks , The relevant requirements of the convenient and efficient supervision and dual prevention management mechanism can be strictly implemented and effectively implemented .

Two 、 Promote the informatization of enterprise safety basic management

Promote the digitalization of enterprise safety basic management 、 Accurate risk warning 、 Systematic risk management and control 、 Unmanned hazardous operation 、 Yun Weifu Help remote , In order to realize the digital transformation of safety risk management and control of hazardous chemical enterprises Energy upgrading injects new kinetic energy .

3、 ... and 、 Get through IOT perception to realize dynamic control

Through digital management means , Get through the perception data of the Internet of things , Realize dynamic evaluation and dynamic management and control according to intelligent algorithm , Precipitation risk factor big data , Further enhance the ability of coordinated joint defense .

Four 、 Improve the level of dynamic and accurate decision-making and command

Through digital management means , Build an intelligent control brain for enterprise risks and hidden dangers , Accurately analyze and manage the situation , Pinpoint management issues and responsibilities , Continuously improve the level of safety decision-making, command and management , Achieve full staff 、 Whole process 、 comprehensive 、 Round the clock management system .

Reference guide for chemical industry parks and major hazard enterprises , Comprehensively carry out platform construction , Combined with the reality , Construction related functions , Improve the ability of safety risk prevention and control . Encourage qualified chemical parks and hazardous chemical enterprises to complete the basic functions and contents of the platform required in the guide , Expand and build functional modules , Improve the application level .

The security risk intelligent management and control platform system needs to establish two ports , Enterprise side and government side . Enterprises should follow the requirements of data exchange specifications , Organize development and construction ( Develop or transform ) Double prevention mechanism information system ( Enterprise end ), In development and transformation , It is necessary to accurately push the investigation tasks according to the construction requirements 、 Hidden danger data is uploaded in real time 、 Basic functions such as timely early warning of abnormal conditions , Realize the online digitization of offline risk early warning information and hidden danger troubleshooting data , Ensure standardized data exchange .

Basic management

Management organization form for multi-level enterprises , Achieve system unification 、 Decentralization, decentralization 、 All personnel are safe 、 Mobile collaboration ;

The system has opened up the supervision of the superior - Group supervision - Control of subsidiaries - The factory workshop implements the four-level management system , And dangerous chemical enterprises and industrial and trade enterprises 、 Production and operation operations and reconstruction and expansion construction are classified uniformly . The personnel of each unit are based on their management level 、 Job categories 、 Different responsibilities and authorities , Enter different functional modules , Convenient handling of daily work , mobile 、 Networking 、 Promotion of information technology 、 Standardization , Breakthrough time 、 Restrictions on location , Realize online business 、 Work convenience .

A chart of risk distribution

Based on industrial Internet and Internet of things technology , Engaged in real-time monitoring after traceability 、 Dynamic warning 、 Global joint control transformation .

Relying on the national risk monitoring and early warning system for safe production of hazardous chemicals , Function improvement , Build a map of risk distribution of hazardous chemicals based on major hazard sources , Monitor the integrity of enterprise risk early warning data , Authenticity of monitoring data , Ensure system stability , Realize the high-risk process device of the enterprise 、 Storage tank farm 、 Real time monitoring and risk early warning of plant leakage monitoring and other data

Intelligent algorithm

Big data and intelligent algorithm based on risk prevention and control , Realize from static trace to dynamic prediction 、 Precise decision-making changes

Major hazard sources of hazardous chemicals based on the enterprise 、 Hazardous chemical processes under key supervision 、 Dangerous chemicals 、 Dynamic monitoring information 、 Risk warning information 、 Safety commitment information 、 Risk classification prevention and control information 、 Hidden danger troubleshooting and treatment information 、 Identification resolution information 、 Transportation information 、 Pipeline risk control information, etc , Run big data AI algorithms , Cluster enterprises or major hazard sources , According to the clustering results of enterprises, the classification system of factory healthy operation is established , Identify the enterprise safety grid and major hazard sources . Urge enterprises to take measures 、 Reduce risk , Accident prevention .

Standardization 、 Promotion of information technology

Based on big data mining and digital archives technology , Realize from repeated reporting to reducing burden and increasing efficiency 、 Digital archives transformation

Automatic mining and analysis technology based on big data , Realize the accurate analysis and positioning of safety production management problems , Visual hierarchical management supporting management decision-making ; Based on Digital Archives Technology , Realize on-site management and process flow and process archives 、 Manage the synchronization and automatic generation of reports , It can not only provide convenience for on-site management , It can also reduce the workload for front-line managers , Truly realize the empowerment and burden reduction through informatization .

supervision

Relying on big data and exponential algorithm , From blind analysis to accurate portrait 、 Index evaluation 、 Differentiated management transformation

Based on safety production big data and exponential algorithm technology , Realize the exponential analysis of the operation effect and situation of safety production management based on personnel and enterprises 、 Visual positioning , Support the scientific decision-making of safety production management , Support leaders at all levels to differentiate their subordinates and enterprises , Carry out differentiated supervision and control , Avoid blind and secondary decision-making difficulties caused by improper application of big data .

边栏推荐

- 一条慢SQL拖死整个系统

- Multithreading and high concurrency (9) -- other synchronization components of AQS (semaphore, reentrantreadwritelock, exchanger)

- Please ask a question, flick Oracle CDC, read a table without update operation, and repeatedly read the full amount of data every ten seconds

- LC 面试题 02.07. 链表相交 & LC142. 环形链表II

- MySql用户权限

- MYSQL----导入导出&视图&索引&执行计划

- MySQL的主从复制原理

- 服装门店如何盈利?

- Bus message bus

- 请问 flinksql对接cdc时 如何实现计算某个字段update前后的差异 ?

猜你喜欢

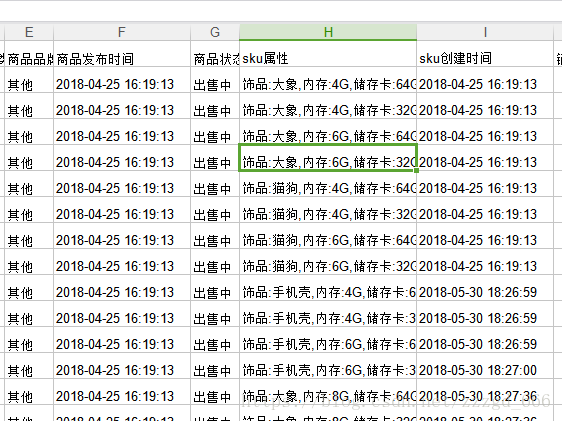

POI export to excel: set font, color, row height adaptation, column width adaptation, lock cells, merge cells

数据资产管理与数据安全国内外最新趋势

JDBC database connection pool usage problem

企业如何进行数据治理?分享数据治理4个方面的经验总结

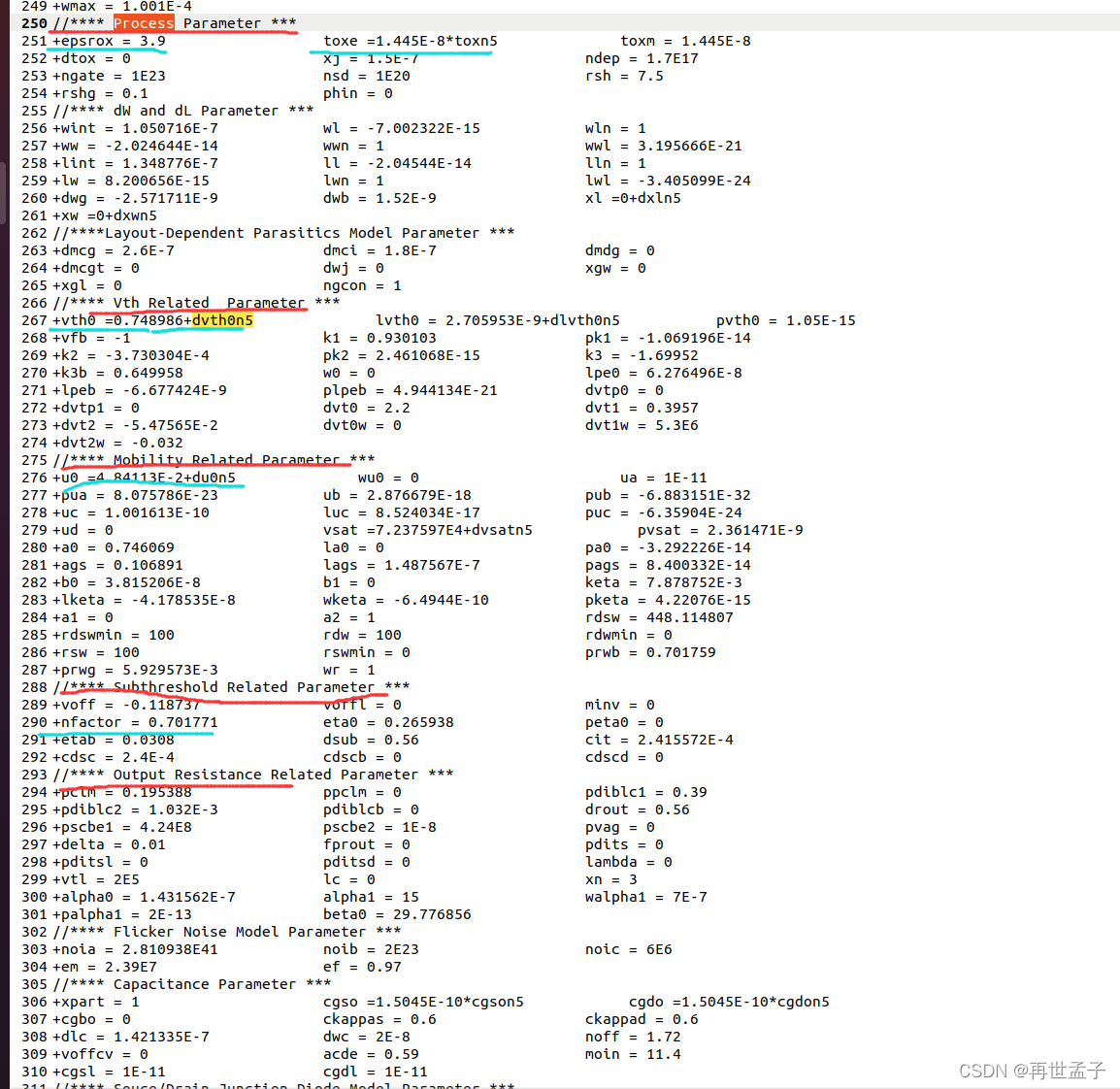

MOS管参数μCox得到的一种方法

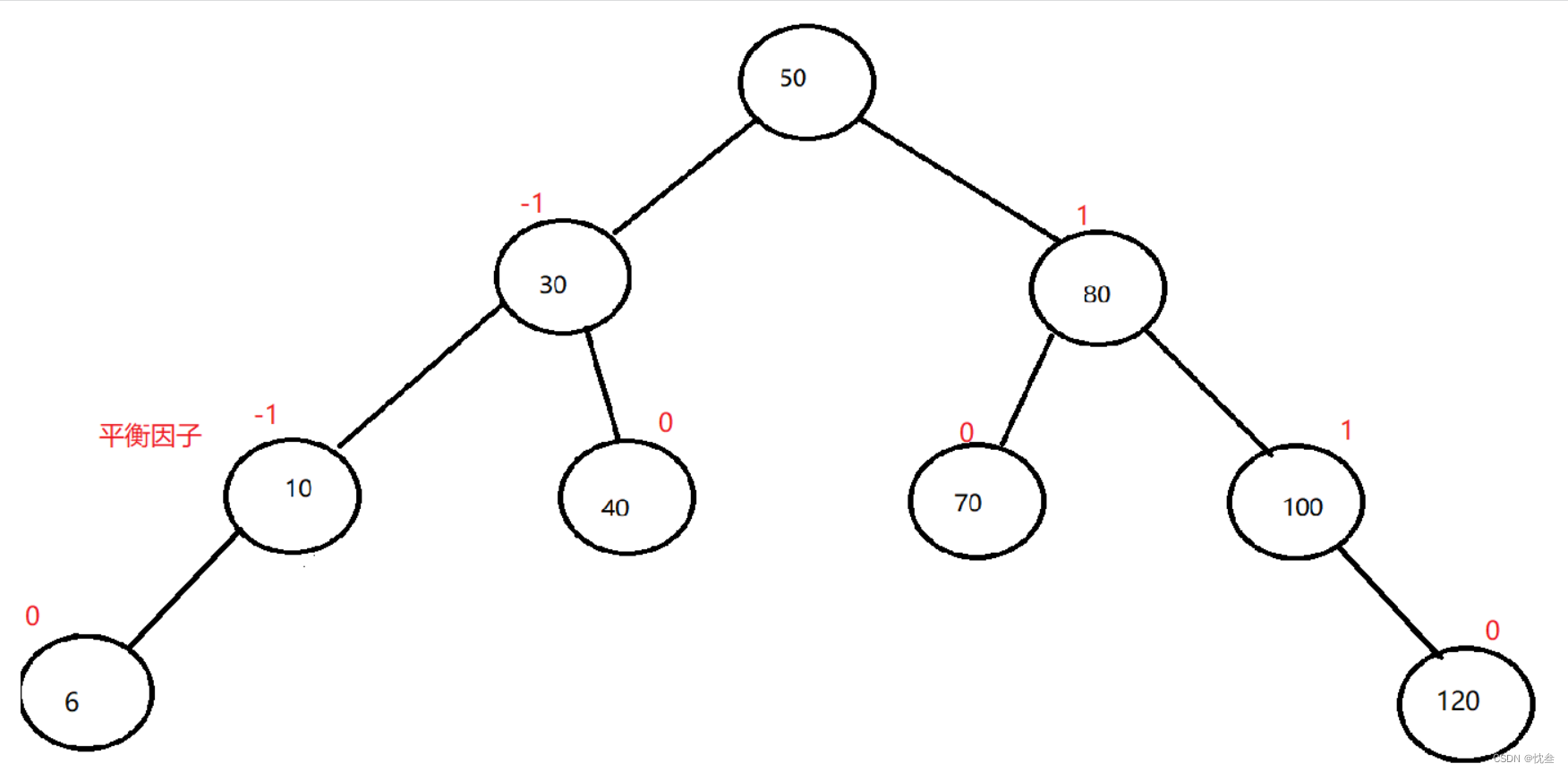

AVL树的实现

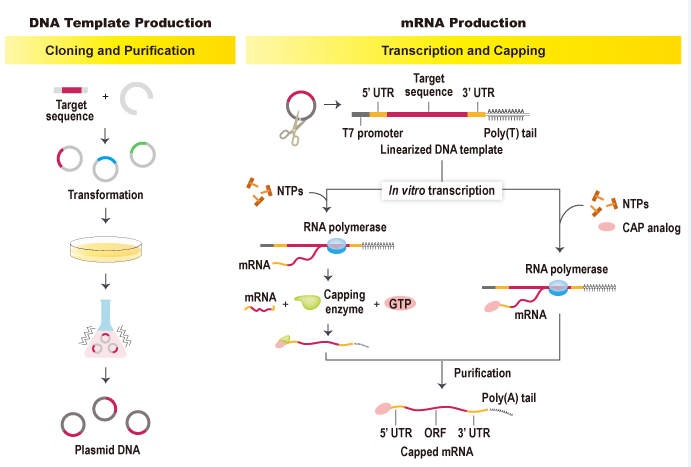

Abnova 体外转录 mRNA工作流程和加帽方法介绍

Graduation design game mall

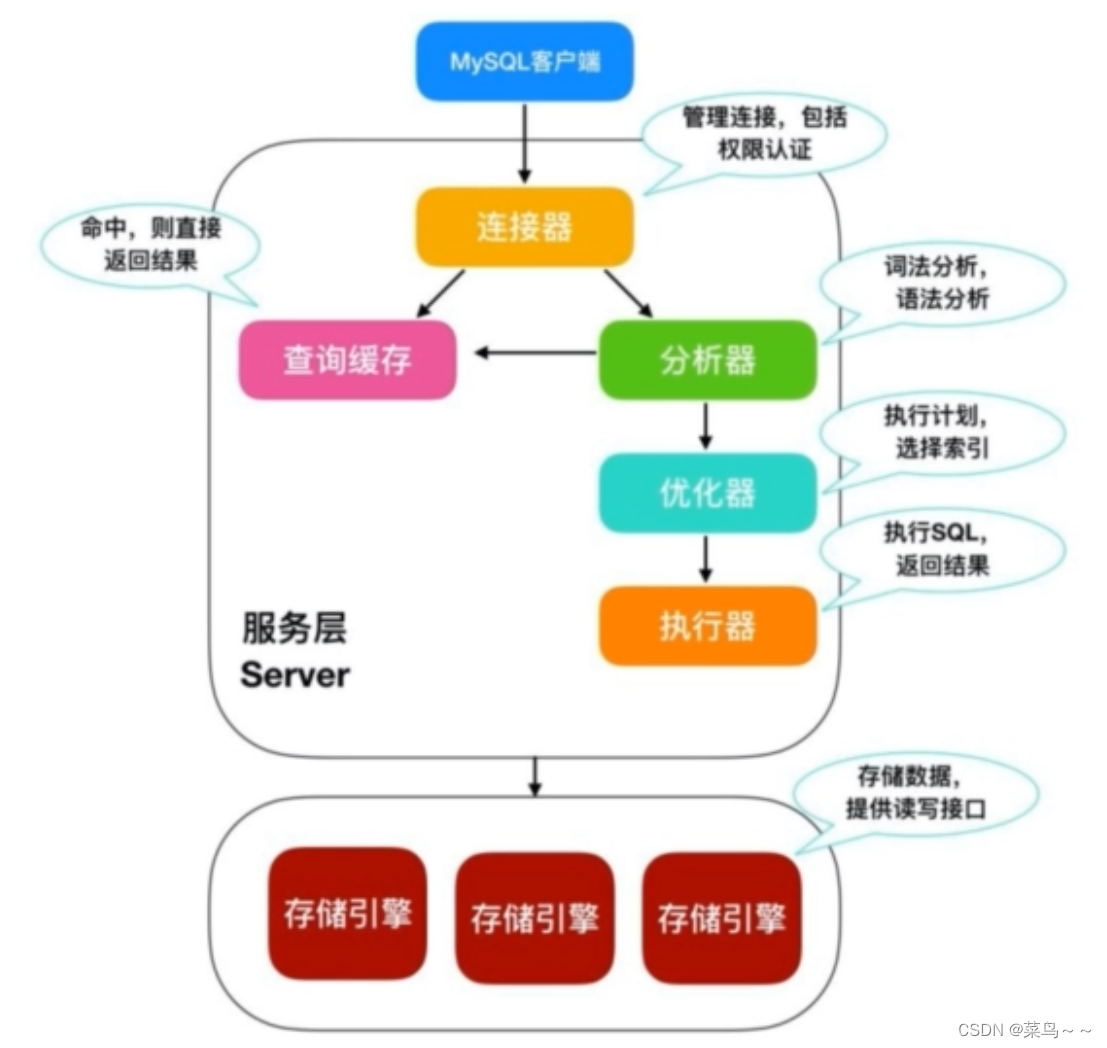

Complete process of MySQL SQL

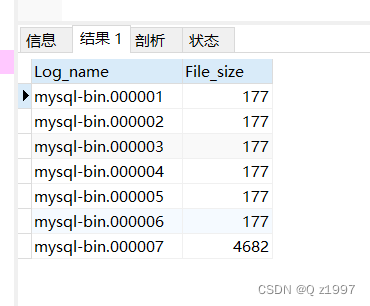

MySQL view bin log and recover data

随机推荐

Master-slave replication principle of MySQL

Graduation design game mall

CompletableFuture使用详解

【mysqld】Can't create/write to file

Take you to brush (niuke.com) C language hundred questions (the first day)

7天零基础能考证HCIA吗?华为认证系统学习路线分享

工具类:对象转map 驼峰转下划线 下划线转驼峰

DHCP路由器工作原理

反射(二)

联合索引ABC的几种索引利用情况

SVN version management in use replacement release and connection reset

FPGA课程:JESD204B的应用场景(干货分享)

The startup of MySQL installed in RPM mode of Linux system failed

How to install swoole under window

leetcode 509. Fibonacci Number(斐波那契数字)

Jetpack Compose 远不止是一个UI框架这么简单~

Answer to the first stage of the assignment of "information security management and evaluation" of the higher vocational group of the 2018 Jiangsu Vocational College skills competition

Stack and queue-p79-9

linux系统rpm方式安装的mysql启动失败

Navicat importing 15g data reports an error [2013 - lost connection to MySQL server during query] [1153: got a packet bigger]