当前位置:网站首页>Schnuka: what is visual positioning system and how to position it

Schnuka: what is visual positioning system and how to position it

2022-07-06 03:26:00 【Schnuka machine vision】

About schnuka

Schnuka (SCHNOKA) Founded on 2010 year , Successively in Shanghai , Suzhou and Wuhan have set up branches . National high tech enterprise , Committed to building a high-tech company with the strongest brain control for intelligent production lines and smart factories . The company revolves around perception & Identify core technologies to build intelligent equipment , Based on robot vision algorithm and single robot workstation 、 Multi robot group integration 、 Industry customized application . Build product systems , For intelligent production line 、 Smart logistics and other scenarios realize software defined intelligence .

SCHNOKA ( Schnuka ) stay 3D Machine vision algorithm 、 Robot flexible control 、 Hand eye collaborative fusion 、 Production line level robot collaboration 、 Plant level intelligent planning and scheduling are applied by leading technologies and industries , In the automotive industry, intelligent sorting production line 、 Large size and high precision three-dimensional measurement 、 He has rich project experience in intelligent sorting of large scene logistics handling robots .

SCHNOKA( Schnuka ) A number of core products of the automotive industry benchmarking production line 、 Lithium new energy lighthouse factory 、 Smart factory of construction machinery 、 Smart logistics and other fields are applied in multiple scenarios . Has cooperated with Baiya international 、 Sound health care 、 Middon group 、 Vida paper 、 faw-vw 、 Shanghai Volkswagen 、 Volvo cars 、 Chery Jaguar Land Rover 、 Geely 、 Changan automobile 、 SAIC GM Wuling 、 Great Wall honeycomb new energy 、 Sany heavy industry 、 AVIC Shenfei 、 China Tunnel Group 、 Siemens high voltage switch 、 China medium car 、ABB( China ) And other well-known enterprises at home and abroad have established good partnership , Won wide praise from head customers .

What is visual positioning system

With the development of science and technology , Visual positioning technology has become the main technology for industrial robots to obtain environmental information , It can realize the improvement of some independent judgment ability in industrial production , Greatly improve the quality and efficiency of work . So , What is the composition of the visual positioning system ? Which parts does it consist of ?

The components of vision system mainly include two aspects , One is the hardware component , One is software development . Let's first look at the hardware components .

1、 Hardware components

The hardware component of vision system mainly includes light source 、 The lens 、 The camera and the interface between the camera and the computer . The functions of these hardware are also as follows : The light source is to enable the basic features of the detected object to be recognized ; The lens is to present a clear image of an object , The camera is mainly used to convert image information into familiar information , The interface between the camera and the computer is to store some video or digital information obtained above , Conduct research . The interface in the visual positioning system usually adopts the acquisition card or USB2.0.

2、 Software development part

The software development part of visual positioning system mainly consists of image acquisition 、 Camera calibration and acquisition of the coordinates of the sending target point are three parts .

(1) Image acquisition

(2) Camera calibration

(3) Get and send the coordinates of the target point

How to locate the visual system

With the vigorous development of industrial automation , Many manufacturers in the production process , There will always be some defects , rejects , Some parts don't match , Some deformed products, etc , Product fit deviation, etc . Sometimes, when the required accuracy cannot be achieved manually , Positioning of machine vision system / aim / Counterpoint . In the process of the following example , Use the positioning of the visual system / aim / Counterpoint , Successfully completed the high-precision manufacturing process .

1. Position the glass printed circuit board

2. Measure the offset of labels and bar codes

3. identify IC The direction of chips, etc

4. Detect the offset of food container cover

5. Control the position of working equipment ( Robot vision ) etc.

边栏推荐

- Derivation of anti Park transform and anti Clarke transform formulas for motor control

- Leetcode problem solving -- 98 Validate binary search tree

- 真机无法访问虚拟机的靶场,真机无法ping通虚拟机

- 出现Permission denied的解决办法(750权限谨慎使用)

- 1003 emergency (25 points), "DIJ deformation"

- These are not very good

- 蓝色样式商城网站页脚代码

- [slam] orb-slam3 parsing - track () (3)

- three. JS page background animation liquid JS special effect

- Brush questions in summer -day3

猜你喜欢

Pointer for in-depth analysis (problem solution)

11. Container with the most water

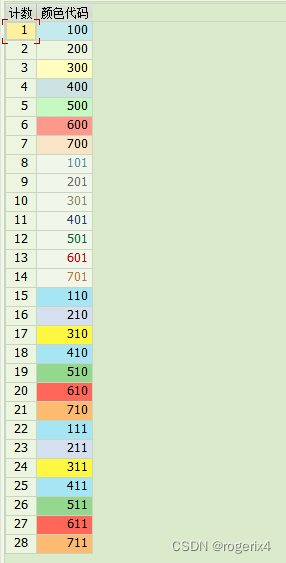

SAP ALV color code corresponding color (finishing)

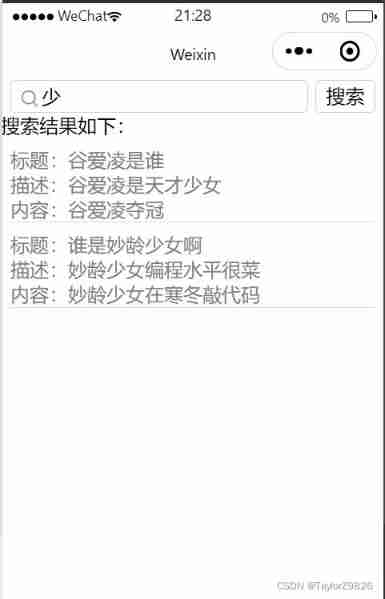

Getting started with applet cloud development - getting user search content

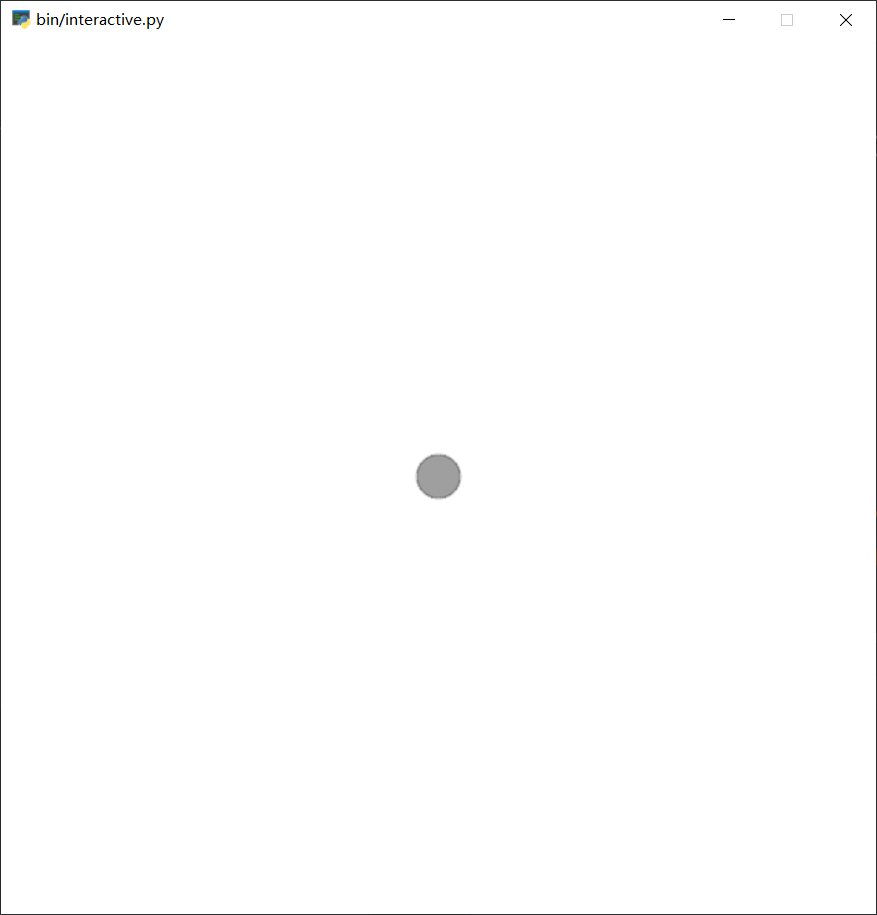

Python implementation of maddpg - (1) openai maddpg environment configuration

蓝色样式商城网站页脚代码

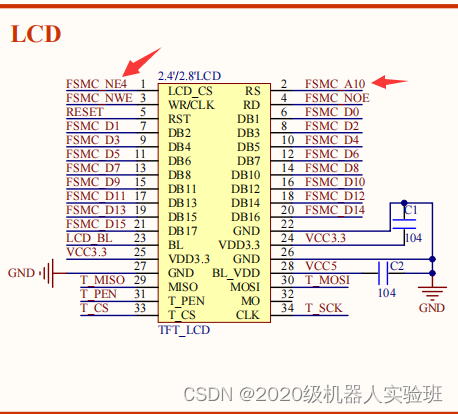

Cubemx 移植正点原子LCD显示例程

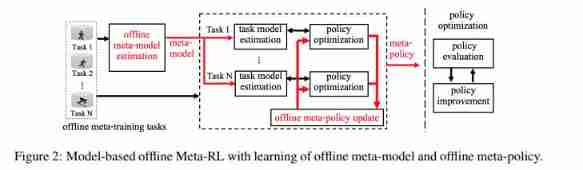

ASU & OSU | model based regularized off-line meta reinforcement learning

Recommended foreign websites for programmers to learn

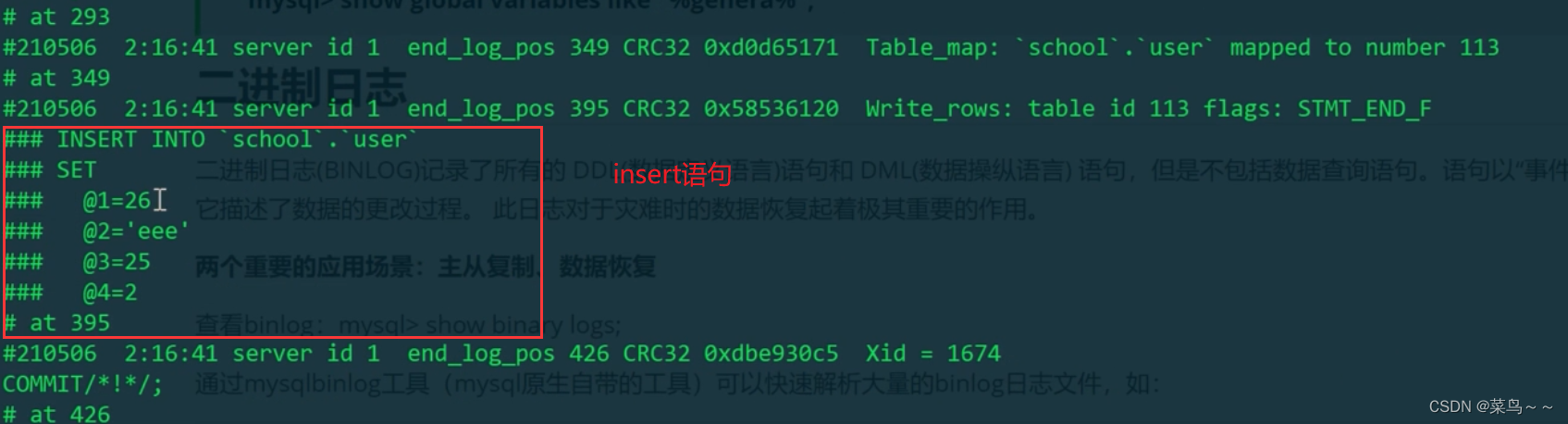

Four logs of MySQL server layer

随机推荐

. Net 6 and Net core learning notes: Important issues of net core

SAP ALV单元格级别设置颜色

[Li Kou] the second set of the 280 Li Kou weekly match

Pytorch基础——(1)张量(tensor)的初始化

暑期刷题-Day3

Redis cache breakdown, cache penetration, cache avalanche

OCR文字識別方法綜述

[rust notes] 18 macro

BUUCTF刷题笔记——[极客大挑战 2019]EasySQL 1

深入刨析的指针(题解)

SWC介绍

Shell 传递参数

[concept] Web basic concept cognition

Deno介绍

EDCircles: A real-time circle detector with a false detection control 翻译

遥感图像超分辨率论文推荐

Computer graduation project asp Net fitness management system VS development SQLSERVER database web structure c programming computer web page source code project

BUAA计算器(表达式计算-表达式树实现)

jsscript

Lua uses require to load the shared library successfully, but the return is Boolean (always true)