当前位置:网站首页>Five reasons for clothing enterprises to deploy MES management system

Five reasons for clothing enterprises to deploy MES management system

2022-07-07 02:37:00 【Dark blue easy net】

In the current economic situation , We found that , Leaders in garment manufacturing often depend on them to be more efficient than their competitors , The ability to operate with higher quality and lower cost . One of their ways to achieve these goals is to deploy MES manufacturing execution system ,MES Management systems enable them to measure performance , Improve the process , raise productivity , And gain general competitive advantage .

raw material / The cost of employing labor and maintaining facilities is increasing , More and more clothing companies are beginning to understand the benefits of lean production , Improve the visibility of daily operations , And more efficient workflow , So as to produce better products , Shorten production time 、 market .MES The management system can help manufacturers realize these advantages by providing detailed real-time data of the workshop , These data can be applied to the continuous improvement plan , At the same time, provide consistent documents and simple root cause analysis in the process .

Increased risk of frequent switching due to the need to provide a large number of products , Therefore, understanding the real-time production data will provide the necessary time and information , To mitigate any factors that may have a negative impact on the production order . By providing continuous real-time data of workshop processes ,MES It can make the manufacturer better understand the existing problems or areas that can be improved .MES The detailed information that the production management system can provide enables manufacturers to operate in a high-speed environment , Make key decisions immediately , And provide operational insight at multiple business levels .

The following is about the deployment of clothing manufacturing enterprises MES Five reasons for management system :

1. visibility

How to provide data to supervisors , Make them understand the accuracy of the production process . The same information , Include availability , Product path and current device status , And other information , At the same time, it can be used by operators on the floor . Provide relevant personnel 、 equipment 、 Real time statistics of raw materials and program direction , Just a few examples. . Unconventional alarms and other measurements can be noted in frequent status updates , Or by text or email .

2. Uniformity

MES Improve security and consistency by replacing paper document processes that rely on physical copies that may be lost or damaged . The system provides information such as recipes 、SOP、BOM、 Access to genealogy and other key data documents that supervisors or operators otherwise have to search manually . Signatures of actions performed by personnel can be recorded electronically , To improve security .

3. Productivity

MES Provides a way to balance people between available resources , Capability of materials and equipment , And these resources can be arranged according to constraints such as urgency or resource requirements . Due to personnel 、 Precise arrangement of materials and equipment , Orders can be optimized to achieve faster product flow . Even with complex schedules , The system can also evaluate and display the running time of each operation , And for periods that take longer than usual , This information can be flagged in the report or sent directly to the employee to determine the root cause .

4. quality

MES The workshop management system can compare the current production index with the previous production index , Old data can be used to identify possible causes of poor results . Production data can be put into one format , In order to determine which orders need more research . Because the production process is monitored every second , Therefore, the operator can be warned when there is a problem , So as to reduce the amount of materials that need to be scrapped or repaired .

5. traceability

Manufacturers are experiencing more and more regulatory requirements to pay more attention to genealogy .MES Be able to associate batch numbers from raw materials to work in process materials with finished products . Because the system can locate the parent component of the product , Therefore use MES Batch tracking can reduce the risk of potential recalls .

边栏推荐

- Ali yunyili: how does yunyuansheng solve the problem of reducing costs and improving efficiency?

- MFC Windows 程序设计[147]之ODBC数据库连接(附源码)

- Go swagger use

- MetaForce原力元宇宙佛萨奇2.0智能合约系统开发(源码部署)

- [C # notes] reading and writing of the contents of text files

- Web3的先锋兵:虚拟人

- How do I dump SoapClient requests for debugging- How to dump SoapClient request for debug?

- 一本揭秘字节万台节点ClickHouse背后技术实现的白皮书来了!

- 服装企业部署MES管理系统的五个原因

- Safety delivery engineer

猜你喜欢

服装企业部署MES管理系统的五个原因

![[paper reading | deep reading] graphsage:inductive representation learning on large graphs](/img/fe/3d4ccfa79a9624ac4901feeea1e69f.png)

[paper reading | deep reading] graphsage:inductive representation learning on large graphs

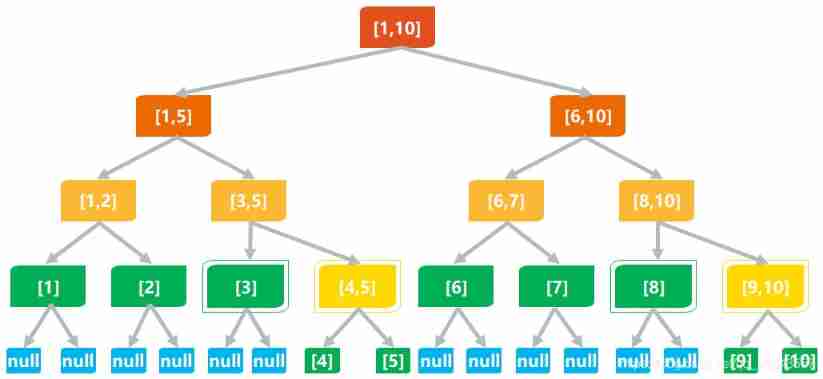

Detailed explanation of line segment tree (including tested code implementation)

Web3的先锋兵:虚拟人

C # / vb. Net supprime le filigrane d'un document word

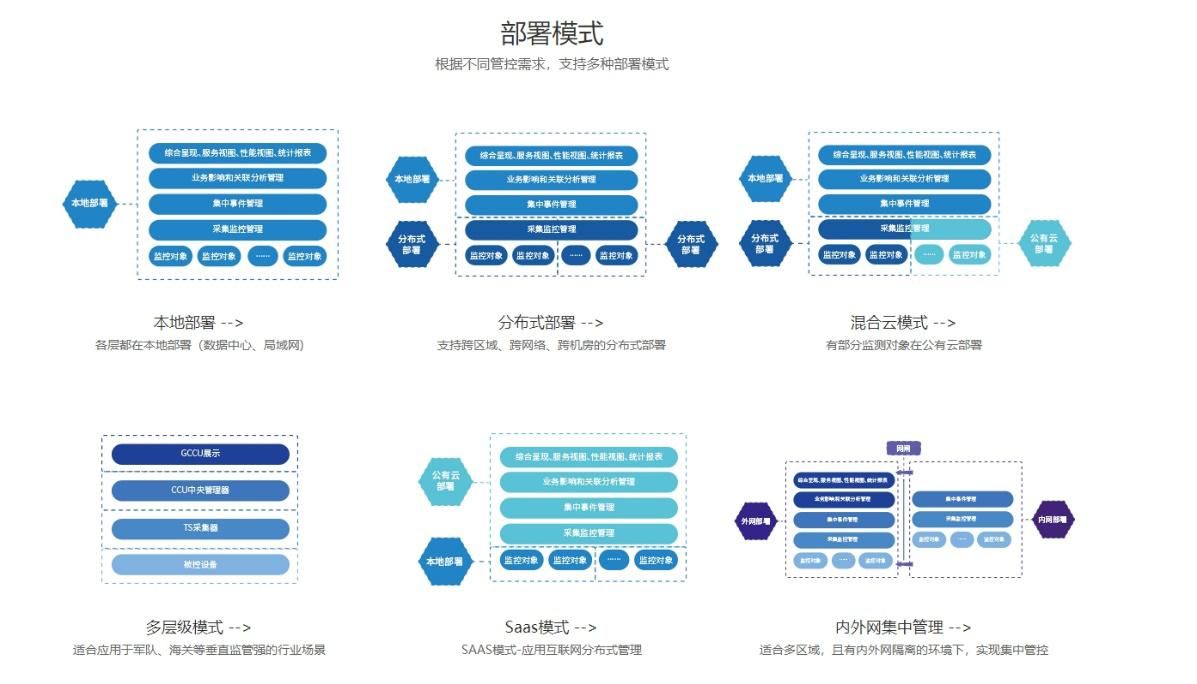

运维管理系统有哪些特色

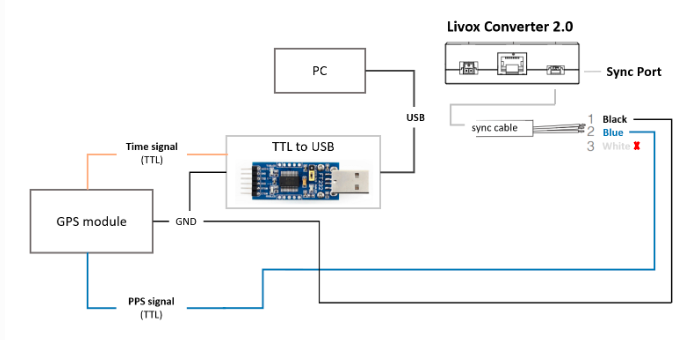

3D laser slam: time synchronization of livox lidar hardware

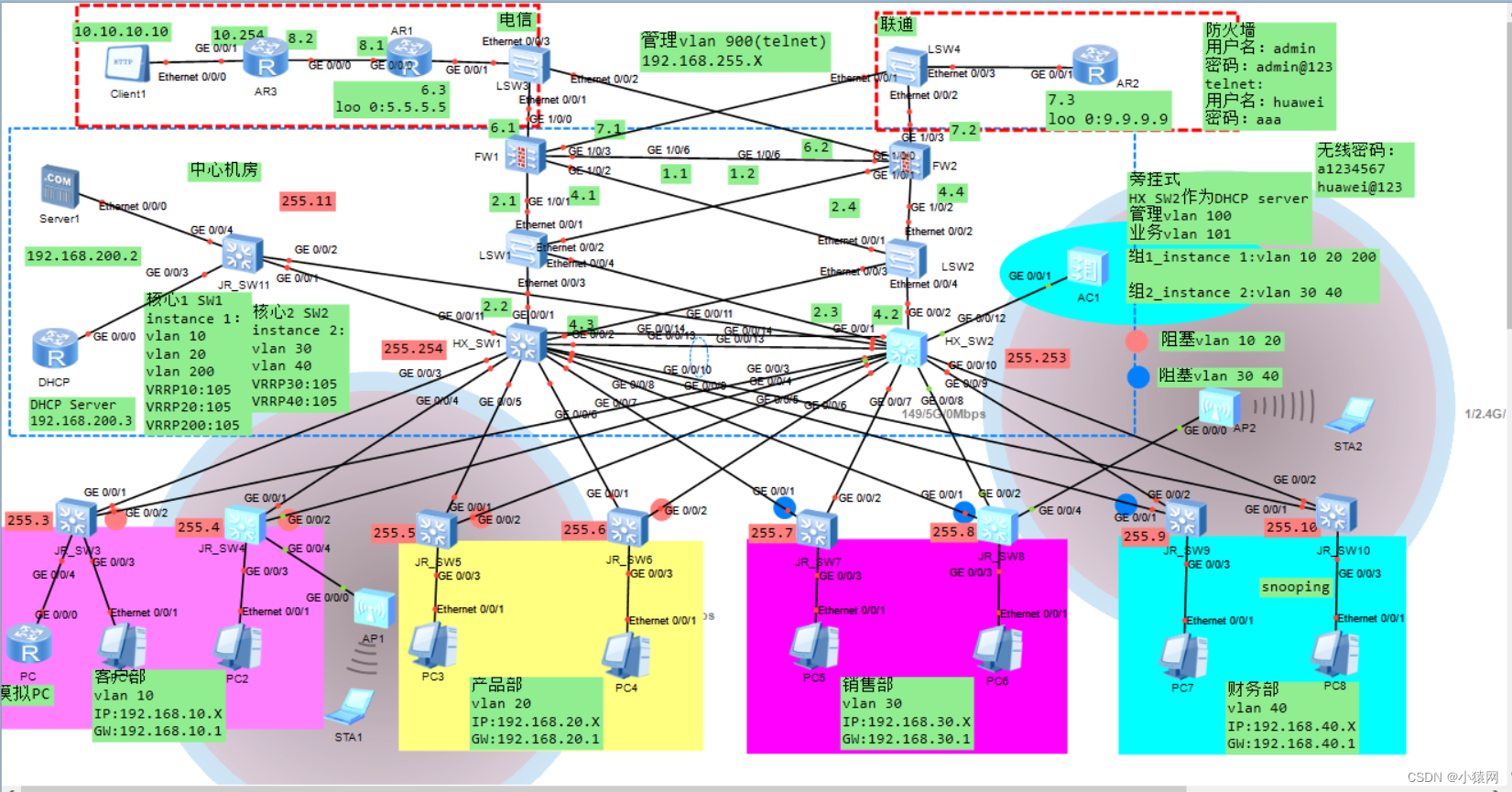

基于ensp防火墙双击热备二层网络规划与设计

Web3's need for law

This week's hot open source project!

随机推荐

Here comes a white paper to uncover the technology behind Clickhouse, a node with 10000 bytes!

GEE升级,可以实现一件run tasks

服装企业部署MES管理系统的五个原因

Unity webgl adaptive web page size

Douban average 9 x. Five God books in the distributed field!

wireshark安装

安全交付工程师

差异与阵列和阵列结构和链表的区别

leetcode:5. Longest palindrome substring [DP + holding the tail of timeout]

记一次JAP查询导致OOM的问题分析

Web3的先锋兵:虚拟人

如何设计好接口测试用例?教你几个小技巧,轻松稿定

Halcon实例转OpenCvSharp(C# OpenCV)实现--瓶口缺陷检测(附源码)

Linear list --- circular linked list

安全巡检的工作

Wireshark installation

真实项目,用微信小程序开门编码实现(完结)

[paper reading | deep reading] rolne: improving the quality of network embedding with structural role proximity

FLIR blackfly s usb3 industrial camera: how to use counters and timers

普通测试年薪15w,测试开发年薪30w+,二者差距在哪?