当前位置:网站首页>Teach you how to select PCB board by hand (II)

Teach you how to select PCB board by hand (II)

2022-07-07 08:33:00 【Fleeting passers-by】

3、 ... and 、 Model selection index

1.PCB Influencing factors :

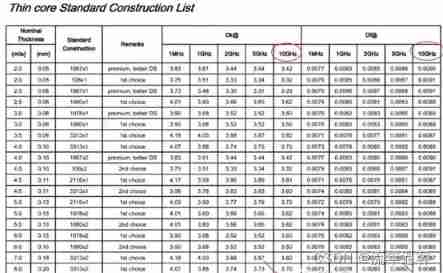

1.1 Dielectric constant Dk

The dielectric constant must be small and stable , Usually the smaller the better . The transmission rate of the signal is inversely proportional to the square root of the dielectric constant of the material , High dielectric constant is easy to cause signal transmission delay . The lower the dielectric constant , The faster the signal transmission .

1.2 Dielectric loss Df

The dielectric loss must be small , This mainly affects the quality of signal transmission , The smaller the dielectric loss , The smaller the signal loss , With the same length of signal line , The stronger the ability to reach the receiving end .

1.3 temperature

frequently-used PCB Media is FR4 Of materials , The dielectric constant relative to air is 4.2-4.7, This dielectric constant changes with temperature , stay 0-70 In degrees , The maximum variation range is 20%. The change of dielectric constant will cause line delay 10% The change of , The higher the temperature, the greater the delay .

1.4 frequency

The dielectric constant will also change with the signal frequency , The higher the frequency, the smaller the dielectric constant . General FR4 Of materials PCB The transmission speed of the inner signal in the board is :

The surface layer generally depends on the situation , Generally in 140-170 Between .

2.Tg、Df:

In principle, choose Tg The higher the value , The smaller the dielectric constant , Plates with smaller dielectric loss .

The following figure shows different frequencies Dk、Df value :

2.1 Tg The value is PCB The critical temperature at which the material melts from solid state to rubber state fluid , It's called Tg spot , Melting point .

(1)Tg The higher the point, the higher the temperature requirement of the plate during pressing , The pressed board will also be hard 、 brittle , To a certain extent, it will affect the quality of mechanical drilling in the subsequent process and the electrical characteristics during use .

(2)Tg The point is the maximum temperature at which the substrate remains rigid (℃), That is, ordinary PCB Substrate material at high temperature , Not only produce softening 、 deformation 、 Melting and other phenomena , At the same time, it is also manifested in mechanical 、 A sharp decline in electrical characteristics .

(3) commonly Tg The plate of 130 Over degrees ,High-Tg It's usually 170-210 degree , secondary Tg about 150-170 degree , The lower Tg about 130-150 degree .

Of the substrate Tg Improved , Heat resistance of printed boards 、 Moisture resistance 、 Chemical resistance 、 Stability and other characteristics will be improved .Tg The higher the value , The better the temperature resistance of the plate , Especially in the lead-free tin spraying process , high Tg More applications .

2.2 Dielectric constant Dk It is the medium that will produce induced charge when applying an electric field and weaken the electric field , The original external electric field ( In a vacuum ) The ratio to the electric field in the final medium is the dielectric constant .

边栏推荐

- Lua 编程学习笔记

- MES系統,是企業生產的必要選擇

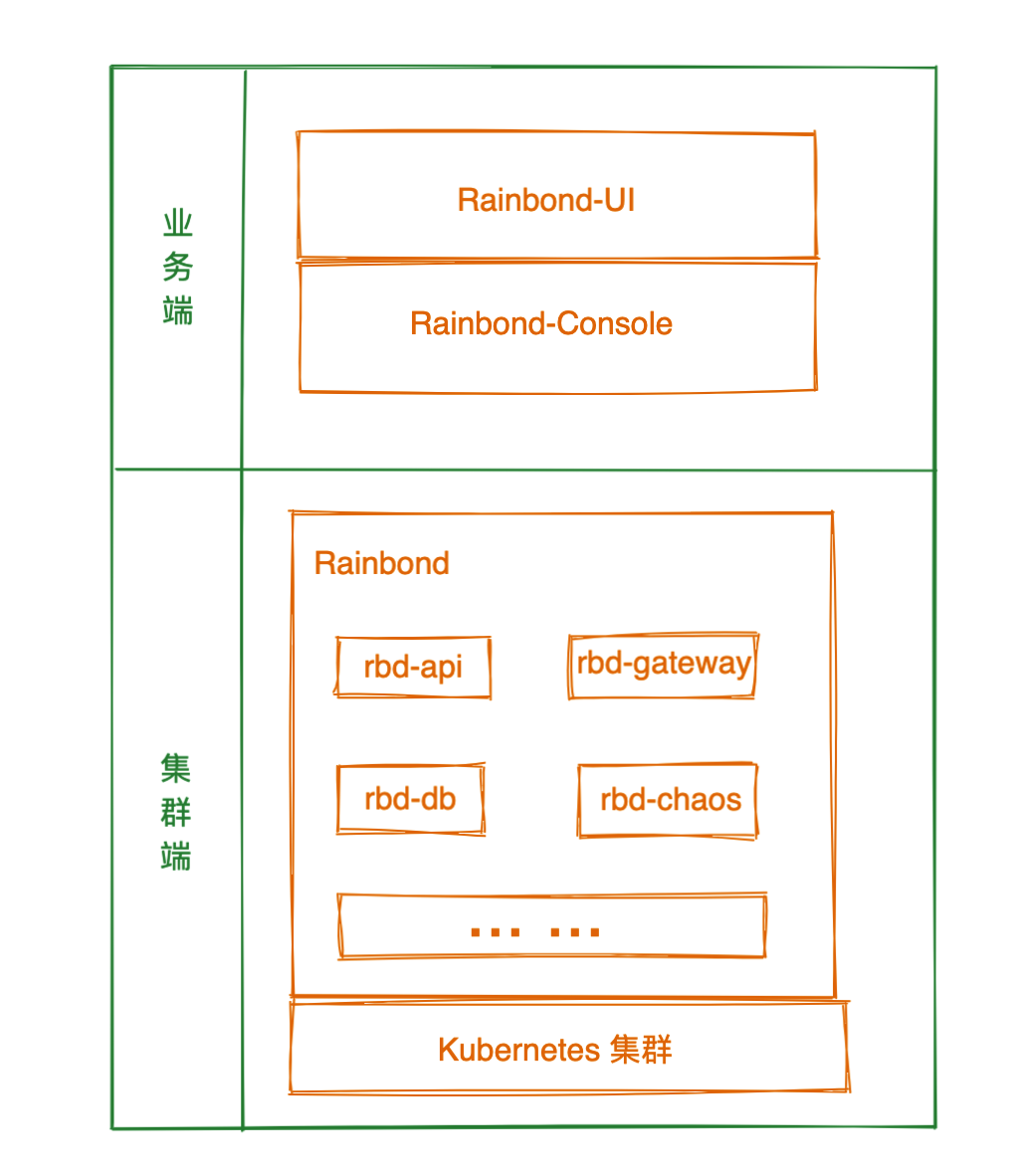

- Using helm to install rainbow in various kubernetes

- POJ - 3616 Milking Time(DP+LIS)

- 【雅思口语】安娜口语学习记录 Part3

- It's too true. There's a reason why I haven't been rich

- 2 - 3 arbre de recherche

- Transformation function map and flatmap in kotlin

- One click installation of highly available Nacos clusters in rainbow

- Opencv learning note 4 - expansion / corrosion / open operation / close operation

猜你喜欢

2-3查找樹

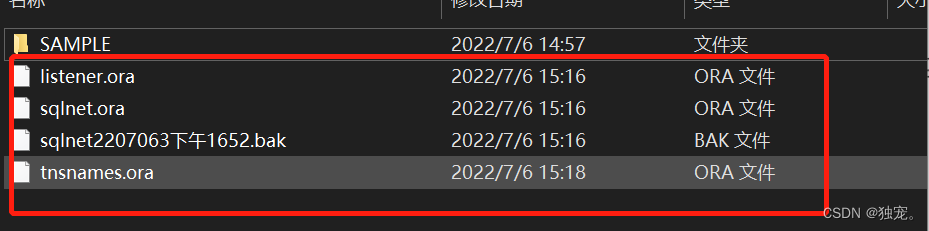

Installation and configuration of PLSQL

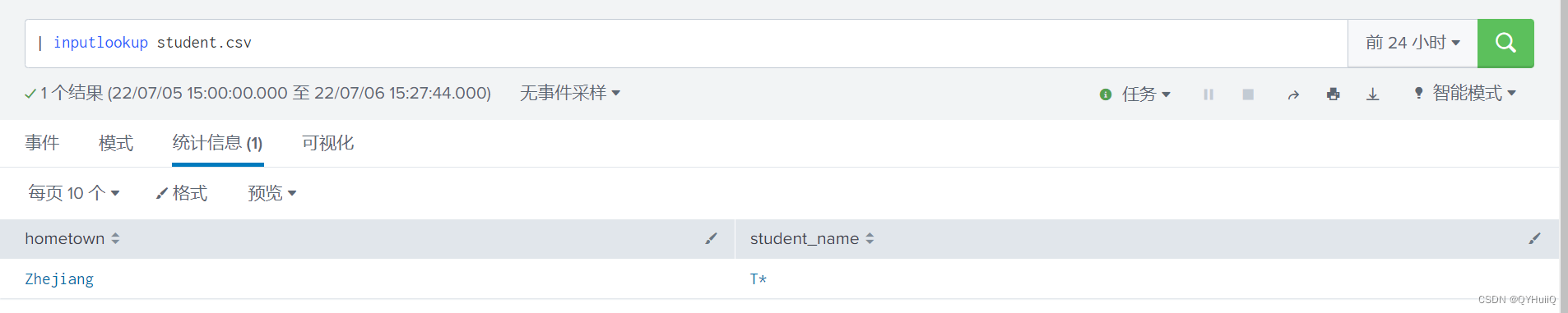

Splunk子查询模糊匹配csv中字段值为*

Implementation of navigation bar at the bottom of applet

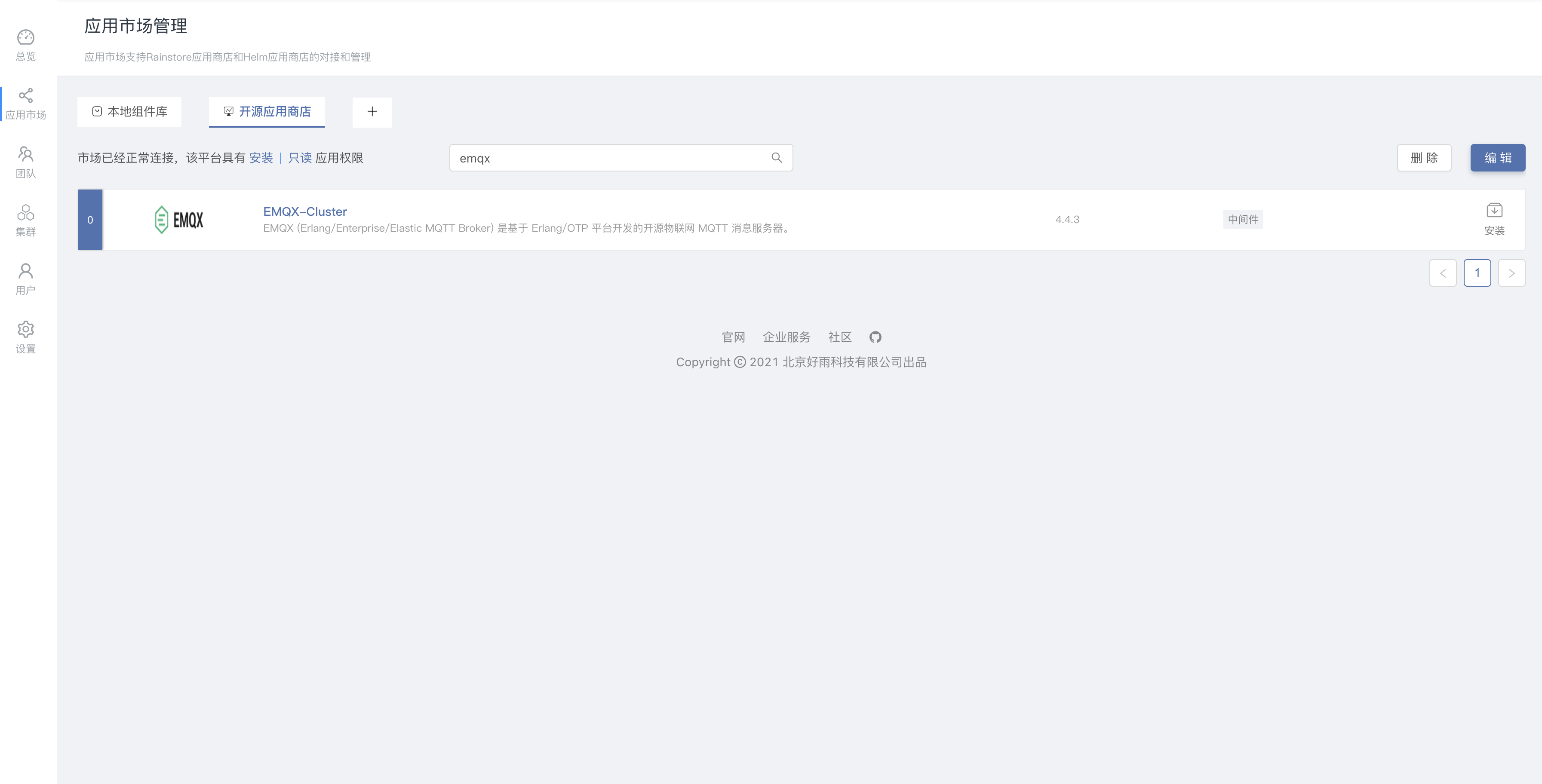

One click deployment of highly available emqx clusters in rainbow

Learn how to compile basic components of rainbow from the source code

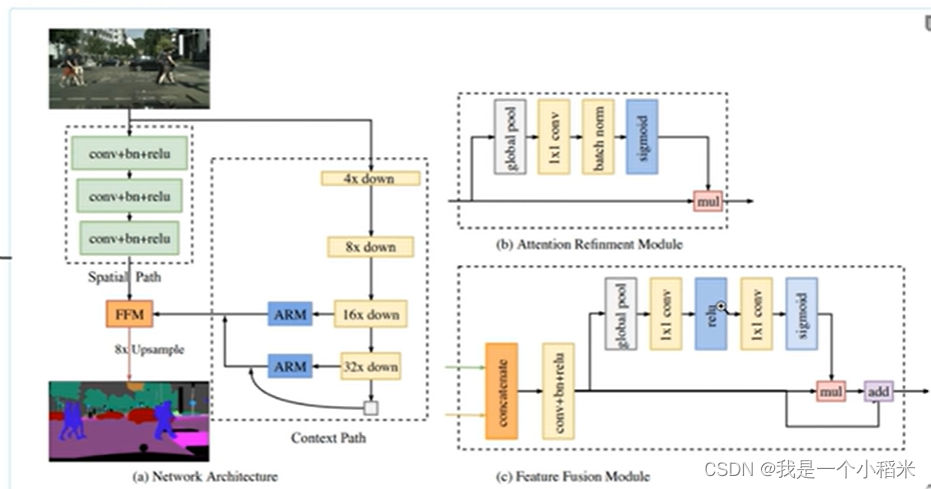

Caractéristiques de bisenet

Opencv learning note 4 - expansion / corrosion / open operation / close operation

Using nocalhost to develop microservice application on rainbow

Open3d ISS key points

随机推荐

POJ - 3616 Milking Time(DP+LIS)

2-3查找树

字符串操作

21 general principles of wiring in circuit board design_ Provided by Chengdu circuit board design

POJ - 3616 Milking Time(DP+LIS)

Iptables' state module (FTP service exercise)

In go language, function is a type

Famine cloud service management script

Explore creativity in steam art design

How to understand distributed architecture and micro service architecture

Practice of combining rook CEPH and rainbow, a cloud native storage solution

[quick start of Digital IC Verification] 10. Verilog RTL design must know FIFO

Obsidan之数学公式的输入

DeiT学习笔记

Function extension, attribute extension and non empty type extension in kotlin

MySQL introduction - crud Foundation (establishment of the prototype of the idea of adding, deleting, changing and searching)

Installation and configuration of PLSQL

Pvtv2--pyramid vision transformer V2 learning notes

国标GB28181协议视频平台EasyGBS新增拉流超时配置

[kuangbin] topic 15 digit DP