当前位置:网站首页>[popular science] basic knowledge of thermal design: heat dissipation analysis of 5g optical devices

[popular science] basic knowledge of thermal design: heat dissipation analysis of 5g optical devices

2022-07-05 04:18:00 【Risehuxyc】

Editor's note : This article is reproduced from Tianfu communication , Some basic knowledge of thermal design is introduced in great detail . For engineers who are concerned about high-speed signal and power integrity , This article is very worth learning .

99% Problems ignored by engineers : Thinking heat and EMI Design considerations for damage

at present 5G It has become a hot topic of global concern , We also rub the heat , Everybody knows ,5G Compared with 4G The download rate should be increased by at least 9~10 times , stay 5G Internet Era , No matter what 5G The bearing scheme is inseparable 5G Communication devices , and 5G The requirements for optical devices are also getting higher , Small volume , High integration , High speed , Low power consumption , in the light of 5G Prequel 、 The main commonly used device rates of intermediate transmission and return transmission are 25G、50G、100G、200G as well as 400G Optical devices , among 25G and 100G Optical devices are the most widely used 5G Communication devices .

The rate is getting higher and higher , Smaller and smaller , This is the inevitable trend of the development of optical devices , At the same time, it also brings higher requirements to the internal thermal management of optical devices , How to heat quickly and effectively is a problem that must be taken seriously .

One 、 Dissipate heat

Why consider thermal design ?

as everyone knows , Our photoelectric chip is working , It will not inject current 100% Convert to output photoelectrons , Part of it will be used as energy loss in the form of heat , If a lot of heat continues to accumulate , It cannot be eliminated in time , It will have many adverse effects on the performance of components , generally speaking , As the temperature rises, the resistance value decreases , Reduce the service life of devices , Poor performance , Material aging , Components are damaged ; In addition, high temperature will also produce stress and deformation on the material , Reduced reliability , Device malfunction, etc .

I have seen a company QSFP-DD 200G modular , When coupling and packaging devices , The module is too hot to touch , The temperature is at least 80℃, Only one side can be coupled , While using the cooling fan , To stabilize the device power , So when considering the device packaging structure , Thermal design is one of the most important considerations .

Let's first popularize the three basic ways of heat transfer : heat conduction 、 Heat convection 、 Thermal radiation

heat conduction : When there is no relative displacement between the parts of the object , Rely on molecules 、 Atoms and free electrons The heat generated by the thermal movement of microscopic examples is called heat conduction . such as , The chip dissipates heat through the heat sink underneath , The optical device contacts the shell for heat dissipation through heat dissipation silicone grease , All belong to heat conduction .

Two 、 Basic knowledge of thermal design

The heat transferred during heat conduction is in accordance with Fourier Calculation of heat conduction law :Q=λA(Th-Tc)/δ

among :A Is the area perpendicular to the direction of heat transfer , Unit is m2;Th And Tc They are the temperature of high temperature and low temperature surfaces respectively ;δ Is the distance between two faces , Unit is m;λ Is the thermal conductivity of the material , Unit is W/(m*℃)

It can be seen from the formula that , Heat conduction process and heat dissipation area 、 Thickness of material 、 thermal conductivity , There is also a relationship between the temperature difference between the contact surface and the heat dissipation surface , Larger area , The thinner the material 、 The greater the thermal conductivity , The more heat is transferred by heat conduction .

In general , The thermal conductivity of a solid is greater than that of a liquid , The of liquid is greater than that of gas . For example, the thermal conductivity of pure copper at room temperature is as high as 400 W/(m*℃), The thermal conductivity of pure aluminum is 210W/(m*℃), The thermal conductivity of water is 0.6 W/(m*℃), And air only 0.025W/(m*℃) about . Aluminum has high thermal conductivity and low density , Therefore, radiators are basically made of aluminum alloy , But in some high-power chip heat dissipation , In order to improve the heat dissipation performance , Aluminum radiator inlaid with copper block or copper radiator is often used .

Give a few examples of heat conduction in life :

① Pan fried vegetables , The iron pot conducts heat and quickly fry the vegetables ;

② When I was a child , Sell popsicles at the door and wrap them in a quilt , Popsicles will not melt for a long time , The quilt has poor heat conduction ;

The following figure summarizes the performance comparison of some commonly used materials as heat sinks :

Our selection rules for heat sink materials :

(1) The thermal conductivity should be high ;

(2) Match the thermal expansion coefficient of the chip ;

It can be seen from the above table , High thermal conductivity , The coefficient of thermal expansion matches the chip material : Tungsten copper alloy 、 Diamond 、 Beryllium oxide 、 Aluminum nitride , Considering the economic cost, the most widely used : copper 、 Tungsten copper 、 Aluminum nitride, etc .

Convective heat transfer : It refers to when a moving fluid flows through a solid surface with a different temperature , The process of heat exchange with the solid surface , This is the most widely used heat exchange method in the heat dissipation of communication equipment .

Convection heat transfer is mainly divided into natural convection heat transfer and forced convection heat transfer :

Natural convection : It mainly uses the buoyancy force caused by the density difference of high and low temperature fluid to exchange heat , It is a passive way of heat dissipation , Applicable to the environment with low calorific value . And on mobile phones 、 End products such as optical modules are mainly natural convection heat transfer .

Forced convection heat transfer : Through the pump 、 Fan and other external power sources to accelerate the speed of fluid heat transfer caused by an efficient way of heat dissipation , Need additional economic input , Suitable for high calorific value 、 Poor cooling environment ; The fan cooling and heat dissipation of optical modules working in cabinets or switches is a typical forced convection heat transfer .

Examples in life :

1、 When the electric teapot is boiling , When opening the lid , Convection of hot and cold water can be seen ;

2、 Open the tea just made with hot water , You can see air convection .

Thermal radiation : Refers to the process of transmitting energy through electromagnetic waves , Thermal radiation is the process of emitting electromagnetic waves when the temperature of an object is higher than absolute zero , The transfer of heat between two objects through thermal radiation is called radiative heat transfer . The formula for calculating the radiation force of the object is :

E=5.67e-8εT4

The calculation of thermal radiation between object surfaces is extremely complex , The simplest two have the same area and

The formula for calculating the radiant heat transfer between the opposite surfaces is :

Q=A*5.67e-8/(1/εh +1/εc -1)*(Th4-Tc4)

In the formula :T It refers to the absolute temperature of the object = Celsius temperature value +273.15;

ε Is the blackness or emissivity of the surface .

Emissivity depends on the kind of substance , Surface temperature and surface condition , It has nothing to do with external conditions , It has nothing to do with color . Apply green oil on the surface of the printed circuit board , Its surface blackness can reach 0.8, This is conducive to radiation and heat dissipation . For metal enclosures , Some surface treatment can be carried out to improve the blackness , Enhance heat dissipation . But here's the thing , Blackening the shell does not necessarily enhance thermal radiation , Because the temperature of the object is lower than 1800℃ when , The wavelength of thermal radiation is mainly concentrated in 0.76~20μm In the infrared band , The proportion of thermal radiation energy in the visible light band is not large . Therefore, blackening the shell or interior of the module can only enhance the absorption of visible light , It has nothing to do with the infrared radiation that brings heat .

Examples in life :

1、 When you are by the fire , There will be a burning sensation ;

2、 The radiation of the sun produces heat .

3、 ... and 、 Thermal analysis of optical devices

The overall heat dissipation path of the device :

The thermal environment of optical devices during operation is shown in the figure below . After the pluggable optical transceiver module is inserted into the panel , A small part of the heat generated inside is dissipated by the natural convection of the surrounding air , Most of them dissipate heat through conduction , Heat is always transferred from the high temperature end to the low temperature end , The module heat is transferred upward to the package shell , Pass it down to the motherboard . The following figure shows the overall schematic diagram of the packaging structure of the optical module , Analyze the main heat dissipation path of the module .

Internal heat dissipation path of optical device :

The main internal heating components include TOSA Launch components 、ROSA Receiving components 、PCB On board devices and IC Control chip . The heat generated by the chip mainly passes through the top ① And the bottom ③ And the side ② Dissipate heat , The heat transmitted from both sides to the outside through the lead frame ②, In fact, because of ①、② Too small to be ignored , To improve the overall heat dissipation efficiency of the module , It needs to be improved as much as possible ③ Heat dissipation capacity , Reduce the size of thermal resistance in each path and improve its thermal conductivity .

Chip heat dissipation path

Important factors affecting the heat dissipation of optical devices :

Through the internal and external analysis of optical devices , It can be seen that the important factors affecting the heat dissipation of optical devices are as follows :

(1) The heat of power devices is exported in time : For devices with high heat flux , Such as under the chip and laser PCB The plate is treated with through-hole copper plug or copper inlaid block , Improve the thermal conductivity of the heat sink .

(2) Thermal conductivity of shell : Under the same heat dissipation conditions , Improving the thermal conductivity of the shell is conducive to reducing the shell temperature of the device , At the same time, it is conducive to reducing the temperature difference between the module shell and the radiator

(3) Device layout : Shorten the distance between the base plate of the heat sink and the heating component , It is conducive to reducing the device shell temperature and the temperature difference between the device shell and the radiator .

(4) Contact thermal resistance : The contact thermal resistance between the device shell and the radiator is an important factor affecting the heat dissipation of the device . Reducing the contact thermal resistance is conducive to improving the heat dissipation performance of the device , Thus, the device shell temperature and the temperature difference between the device shell and the radiator are reduced .

(5) The contact area between the radiator and the device shell : By increasing the length of the radiator contact surface , The device shell temperature and the temperature difference between the device shell and the radiator can be reduced by about 1-2 ℃.

Four 、 Thermal simulation example

With TOSA For example , Through difference Receptacle The structure design of the can see the curve of temperature changing with time , As shown in the figure below , Through thermal simulation, it is known that the temperature difference between the two structures reaches 5℃ about .

边栏推荐

- Mixed compilation of C and CC

- Ctfshow web entry code audit

- PR video clip (project packaging)

- NetSetMan pro (IP fast switching tool) official Chinese version v5.1.0 | computer IP switching software download

- 陇原战“疫“2021网络安全大赛 Web EasyJaba

- How to remove installed elpa package

- 【虚幻引擎UE】实现测绘三脚架展开动画制作

- Behavior perception system

- web资源部署后navigator获取不到mediaDevices实例的解决方案(navigator.mediaDevices为undefined)

- 行为感知系统

猜你喜欢

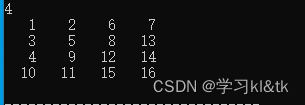

Serpentine matrix

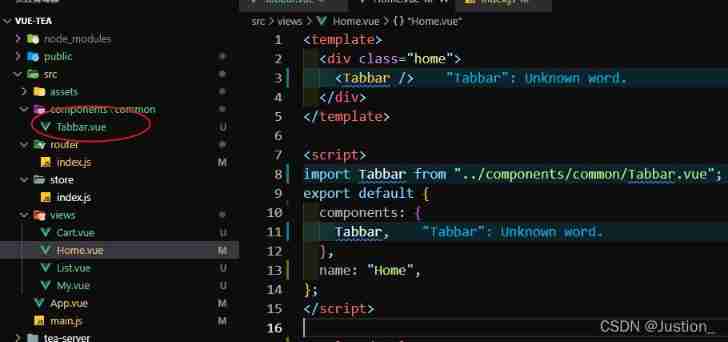

3. Package the bottom navigation tabbar

A solution to the problem that variables cannot change dynamically when debugging in keil5

美国5G Open RAN再遭重大挫败,抗衡中国5G技术的图谋已告失败

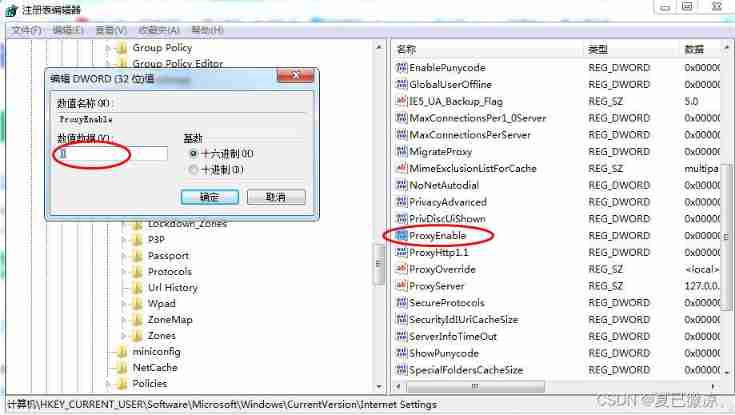

Why can't all browsers on my computer open web pages

【UNIAPP】系统热更新实现思路

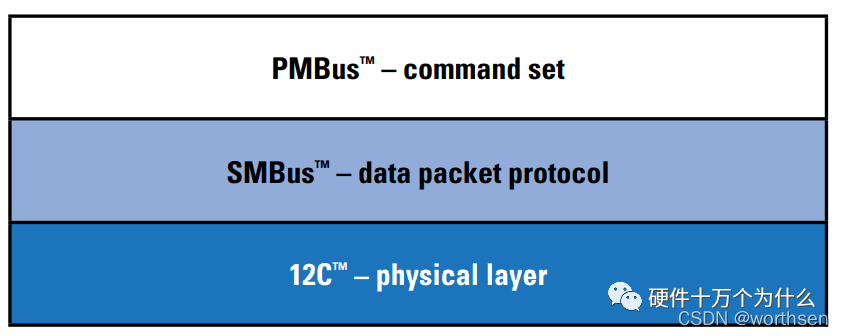

电源管理总线 (PMBus)

TPG x AIDU|AI领军人才招募计划进行中!

“金九银十”是找工作的最佳时期吗?那倒未必

As soon as I write the code, President Wang talks with me about the pattern all day

随机推荐

Study notes 7

Moco is not suitable for target detection? MsrA proposes object level comparative learning target detection pre training method SOCO! Performance SOTA! (NeurIPS 2021)...

Fuel consumption calculator

Ctfshow 2022 Spring Festival welcome (detailed commentary)

OWASP top 10 vulnerability Guide (2021)

这是一个不确定的时代

NetSetMan pro (IP fast switching tool) official Chinese version v5.1.0 | computer IP switching software download

About the project error reporting solution of mpaas Pb access mode adapting to 64 bit CPU architecture

Ctfshow web entry code audit

JVM garbage collection

Threejs Internet of things, 3D visualization of factory

Rome chain analysis

Online text line fixed length fill tool

Sequence diagram of single sign on Certification Center

长度为n的入栈顺序的可能出栈顺序种数

American 5g open ran suffered another major setback, and its attempt to counter China's 5g technology has failed

快手、抖音、视频号交战内容付费

Hexadecimal to octal

DFS and BFS concepts of trees and graphs

Seven join join queries of MySQL