当前位置:网站首页>Design and Simulation of fuzzy PID control system for liquid level of double tank (matlab/simulink)

Design and Simulation of fuzzy PID control system for liquid level of double tank (matlab/simulink)

2022-07-05 10:08:00 【Chloroplasts don't forget to breathe】

WeChat official account : Chuangxiang diary

send out : Double volume blur

Get a complete watermark free report + Simulation source file + Related literature

One 、 Problem description

Design and Simulation of liquid level control system of double tank

1、 Based on the principle of liquid level balance , Establish the mathematical model of the liquid level control system of double tank , And the linearization model is established by using the equilibrium point linearization method ;

2、 Use fuzziness PID Control method , Online adjustment PID The parameters of the controller , Realize the liquid level adjustment of double tank , Give a detailed control scheme ;

3、 use Simulink Build simulation block diagram , Realize the simulation of the system , Online adjustment PID Parameters , And analyze the system performance .

Two 、 model

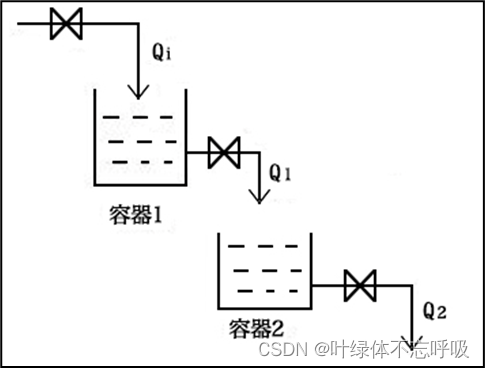

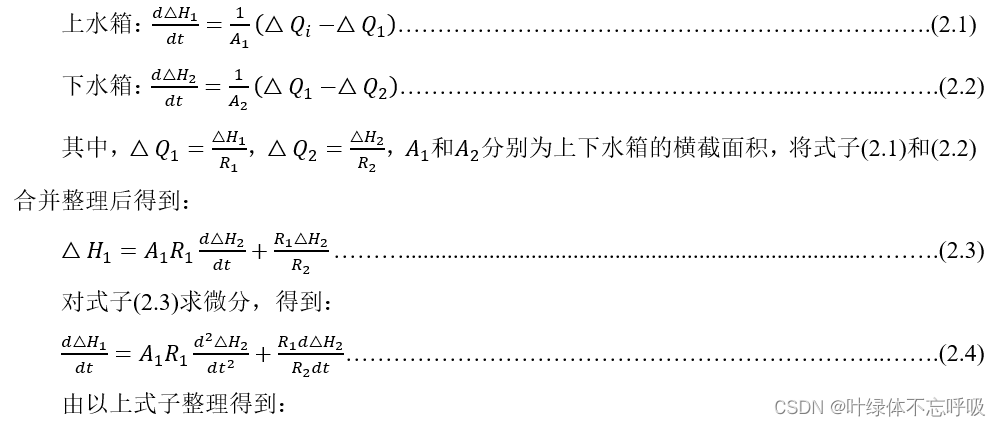

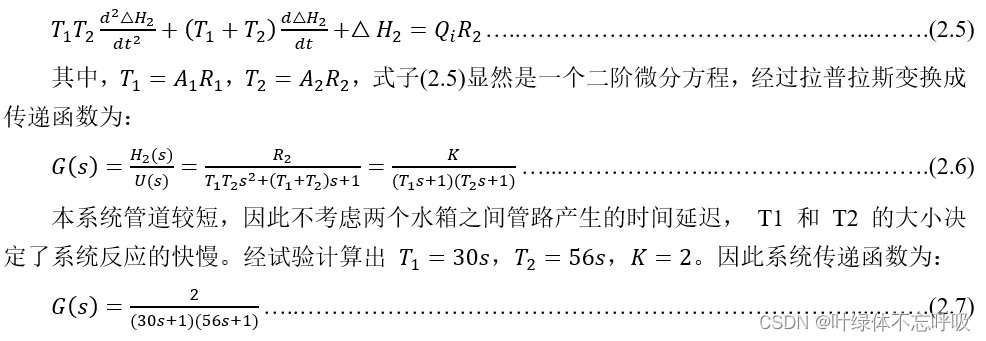

The structure diagram of double tank system is shown in the figure 1-1 Shown , Inlet valve of upper water tank V_i( Liquid resistance is R_i) The opening of the controls the inflow of the upper water tank Q_i, Outlet valve V_1( Liquid resistance is R_1) The outflow is Q_1, The liquid level of the upper water tank H_1 from Q_i and Q_1 To make sure ; Lower water tank inlet valve V_1 The inflow is Q_1, Outlet valve V_2( Liquid resistance is R_2) The outflow is Q_2, Liquid level of lower water tank H_2 According to the water inflow Q_1 And water yield Q_2 Jointly determine . In the process of control V_1 and V_2 remain unchanged , The main control task of the system is to adjust V_i To control the liquid level of the lower water tank H_2, Make the measured value equal to the set value , The following equations are listed according to the dynamic material balance relationship :

3、 ... and 、 Control plan

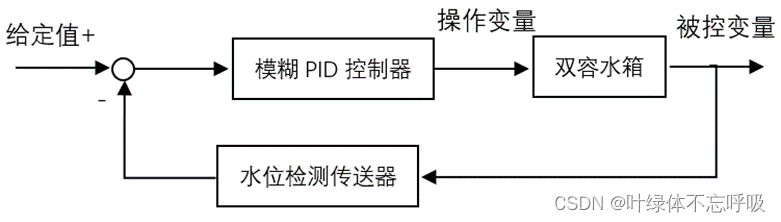

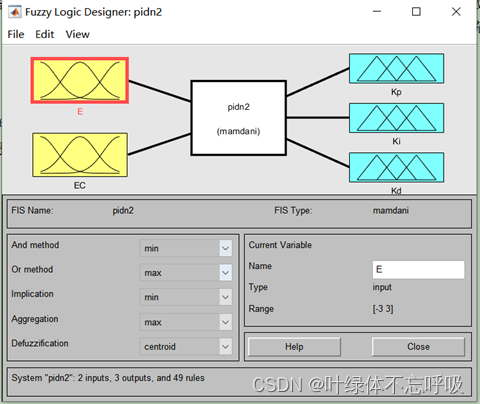

The dual tank control system adopts fuzzy PID Control method , The system structure block diagram is shown in Figure (3-1) Shown .

1、 Fuzzy PID Implementation steps of the control scheme

(1) stay Matlab Command line window input fuzzy Call out fuzzy logic designer Window for compilation .

(2) Set the number of input and output , Pictured (3-2) Shown , And set the number of inputs to 2, The range is [-3,3], The number of outputs is 3, The range is [-1,1].

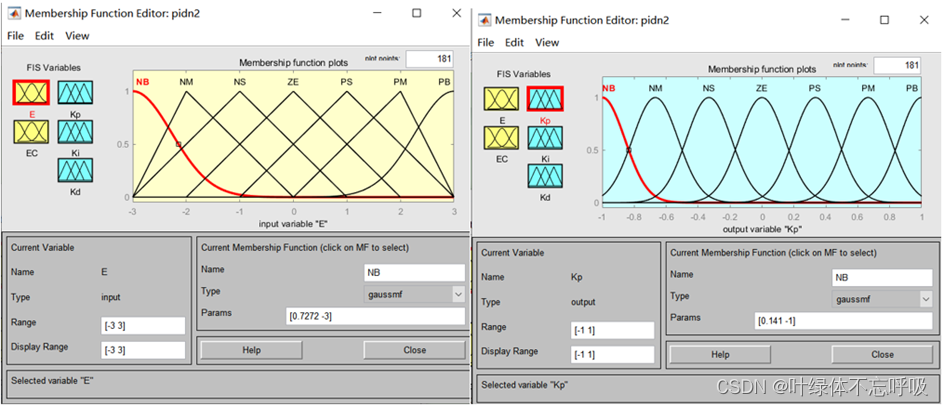

(3) Edit its membership function according to relevant data , Pictured (3-3).

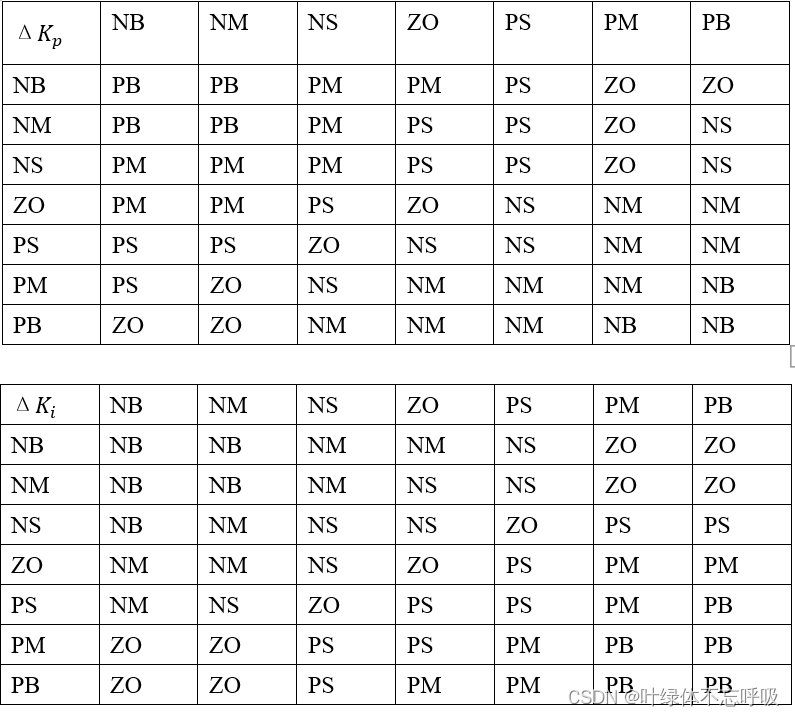

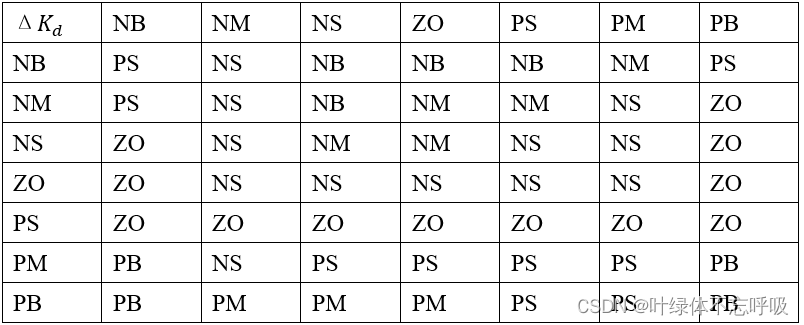

(4) Design fuzzy rules according to the following rules (NB Is negative ,NM Is negative ,NS Negative small ,ZO zero ,PS Is positive small ,PM For the center ,PB For Zhengda ), The horizontal axis of the following table is EC, The vertical axis is E.

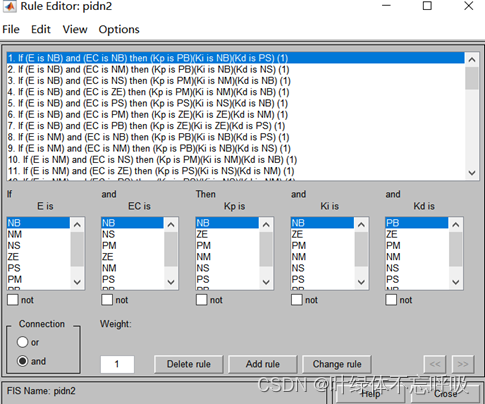

Write rules according to the above table , Such as :

If (E is NB) and (EC is NB) then (∆K_p is PB)(∆K_i is NB)(∆K_d is PS) (1)

If (E is NB) and (EC is NM) then (∆K_p is PB)(∆K_i is NB)(∆K_d is NS) (2)

If (E is NB) and (EC is NS) then (∆K_p is PM)(∆K_i is NM)(∆K_d is NB) (3)

… altogether 49 Bar rule , I'm not going to list one by one , Pictured (3-4) Shown .

Make rules and save , And export to workspace To be used .

2、 Blurring PID Parameter self-tuning

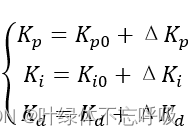

According to relevant information, we can see that K_p0、K_i0、K_d0 Is the initial value PID The parameter setting principle is

In style ,K_p、K_i、K_d Respectively fuzzy self-tuning PID Output gain ;K_p0、K_i0、K_d0 They are the initial value of gain ;ΔK_p、ΔK_i、ΔK_d Respectively, the adjustment amount of gain .

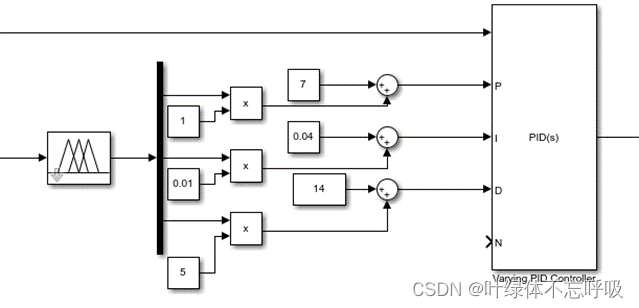

Pictured (3-5) Shown as fuzzy PID The overall structure of control . stay sum The following values are gain output K_p、K_i、K_d. In the picture 7、0.04 and 14 They are the initial value of gain K_p0、K_i0、K_d0, Its value is determined by the traditional PID By experience , Follow the following formula :

Parameter setting to find the best , From childhood to great order ;

First proportion, then integral , Finally, we add the differential to ;

The curve oscillates frequently , Scale up the dial ;

The curve floats around the Bay , Pull the scale dial towards the small side ;

Curve deviation recovery is slow , The integral time goes down ;

The curve fluctuates for a long period , The integral time is longer ;

Fast curve oscillation frequency , Let's lower the differential first ;

The movement is big and the fluctuation is slow . The differential time should be longer ;

Ideal curve two waves , The front is high and the back is low 4 Than 1;

One look, two tone and multi analysis , The adjustment quality will not be low .

After getting the initial value , Because the set output universe is [-1 1], Therefore, in demux Then multiply by the corresponding value range , The output value after multiplication is the adjustment amount of gain ΔK_p、ΔK_i、ΔK_d.

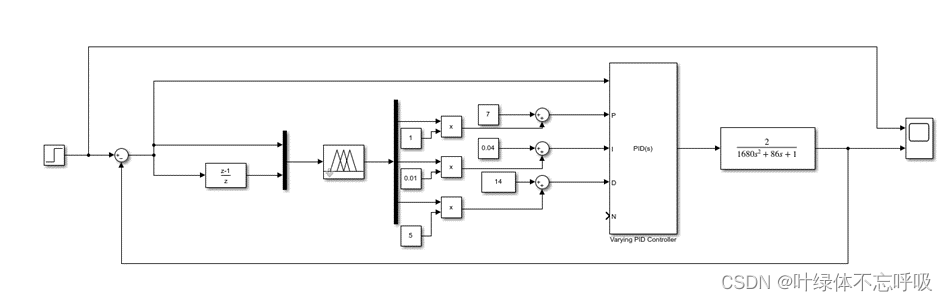

Four 、 Simulation verification

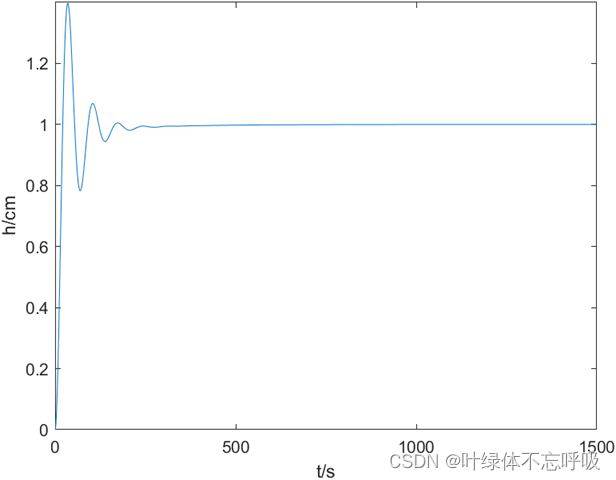

stay Matlab/Simulink As shown in the picture (4-1) The double tank shown is fuzzy PID Control system simulation model , Edit the editors of the fuzzy controller , take 49 A fuzzy control rule is written into the fuzzy control rule editor , Finally, the clear value of the data output is obtained to realize PID Online parameter setting , The simulation results are shown in the figure (4-2) Shown . The blue line is the system response , The yellow line is the unit step given . The response overshoot is 0.397, The time to reach steady state is 1496s.

5、 ... and 、 Systems analysis

The most commonly used in traditional control theory is routine PID control , Its algorithm is simple and practical , It has good control effect and robustness in control , But for liquid level control, it is nonlinear 、 The control system with time-varying characteristics needs to PID Parameters can be adjusted online continuously to obtain better control effect . In practical application, due to PID Parameters vary , There is no definite mathematical model and law to follow , Fuzzy control can make full use of the successful practical experience of operators in real-time nonlinear regulation , Therefore, this system adopts fuzzy controller PID Online parameter setting , Give full play to PID The excellent control function of the controller makes the system achieve the best effect .

边栏推荐

- 天龙八部TLBB系列 - 关于技能冷却和攻击范围数量的问题

- Resolve the horizontal (vertical) sliding conflict between viewpager and WebView

- 百度智能小程序巡检调度方案演进之路

- 苹果 5G 芯片研发失败?想要摆脱高通为时过早

- 单片机原理与接口技术(ESP8266/ESP32)机器人类草稿

- [C language] the use of dynamic memory development "malloc"

- How to use sqlcipher tool to decrypt encrypted database under Windows system

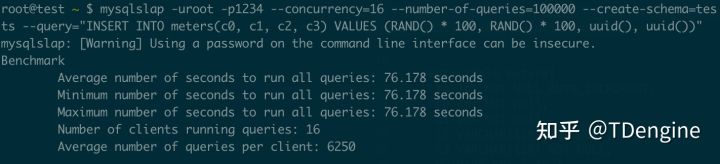

- 写入速度提升数十倍,TDengine 在拓斯达智能工厂解决方案上的应用

- What are the advantages of the live teaching system to improve learning quickly?

- Those who are good at using soldiers, hide in the invisible, and explain the best promotional value works in depth in 90 minutes

猜你喜欢

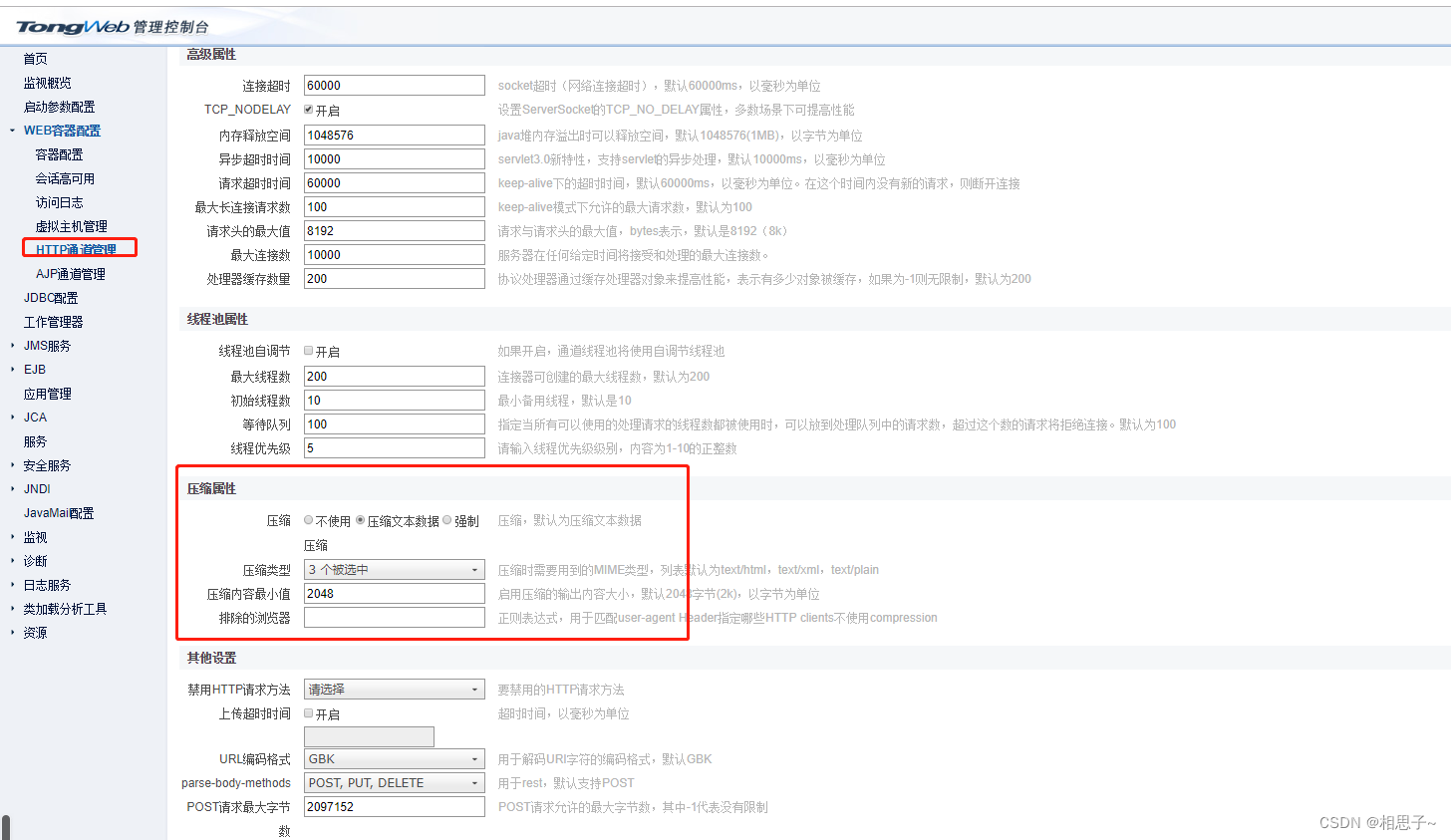

Tongweb set gzip

为什么不建议你用 MongoDB 这类产品替代时序数据库?

Single chip microcomputer principle and Interface Technology (esp8266/esp32) machine human draft

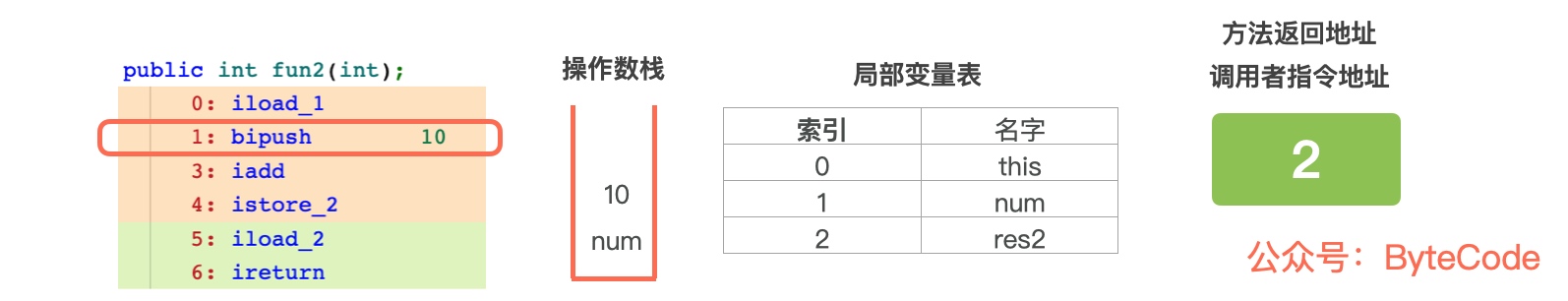

卷起來,突破35歲焦慮,動畫演示CPU記錄函數調用過程

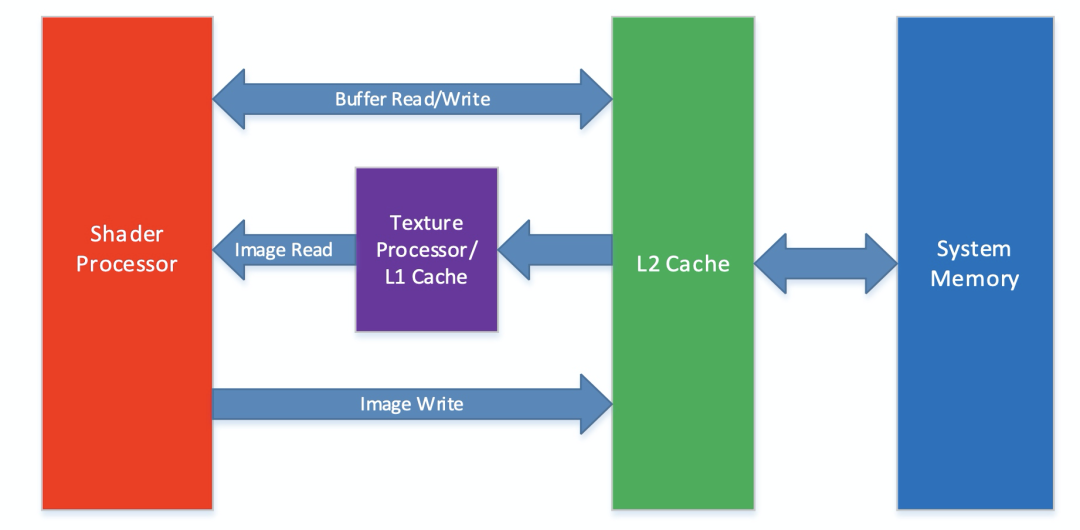

Mobile heterogeneous computing technology GPU OpenCL programming (Advanced)

![[NTIRE 2022]Residual Local Feature Network for Efficient Super-Resolution](/img/f3/782246100bca3517d95869be80d9c5.png)

[NTIRE 2022]Residual Local Feature Network for Efficient Super-Resolution

Is it really reliable for AI to make complex decisions for enterprises? Participate in the live broadcast, Dr. Stanford to share his choice | qubit · viewpoint

让AI替企业做复杂决策真的靠谱吗?参与直播,斯坦福博士来分享他的选择|量子位·视点...

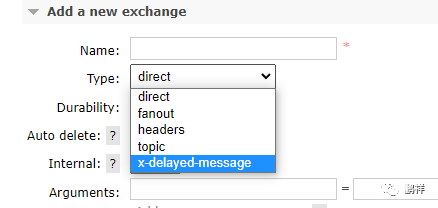

.Net之延迟队列

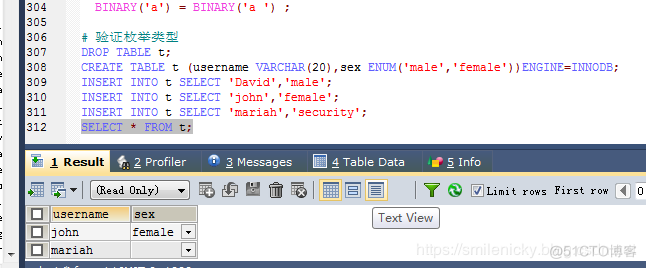

MySQL character type learning notes

随机推荐

MySQL数字类型学习笔记

Node-RED系列(二九):使用slider与chart节点来实现双折线时间序列图

What should we pay attention to when developing B2C websites?

从“化学家”到开发者,从甲骨文到TDengine,我人生的两次重要抉择

卷起来,突破35岁焦虑,动画演示CPU记录函数调用过程

Optimize database queries using the cursor object of SQLite

QT realizes signal transmission and reception between two windows

TDengine ×英特尔边缘洞见软件包 加速传统行业的数字化转型

What are the advantages of the live teaching system to improve learning quickly?

Coffeescript Chinese character to pinyin code

Is it really reliable for AI to make complex decisions for enterprises? Participate in the live broadcast, Dr. Stanford to share his choice | qubit · viewpoint

Single chip microcomputer principle and Interface Technology (esp8266/esp32) machine human draft

Apache DolphinScheduler 系统架构设计

Officially launched! Tdengine plug-in enters the official website of grafana

一文读懂TDengine的窗口查询功能

Android SQLite database encryption

解决Navicat激活、注册时候出现No All Pattern Found的问题

Meitu lost 300 million yuan in currency speculation for half a year. Huawei was exposed to expand its enrollment in Russia. Alphago's peers have made another breakthrough in chess. Today, more big new

Baidu app's continuous integration practice based on pipeline as code

Community group buying has triggered heated discussion. How does this model work?