当前位置:网站首页>MES system is a necessary choice for enterprise production

MES system is a necessary choice for enterprise production

2022-07-07 08:21:00 【Huidu technology intelligent manufacturing】

Most domestic manufacturing industries are Discrete small and medium-sized enterprises , So how to tap the potential of small and medium-sized enterprises 、 Increase of efficiency 、 cost reduction 、 Through internal structure adjustment and process rectification , Improve market adaptability , Speed up the flow of information , Carry out lean production in the workshop , Informatization management and informatization means are the only choices . Especially for small and medium-sized discrete manufacturing enterprises ,MES The system is more suitable for its flexibility 、 Changeable production and processing characteristics .

MES The system is the upper layer of the enterprise ERP And the automatic control system of the underlying equipment 、 Workshop level oriented management system , It aims to collect the production process data 、 Integrate and make full use of , In the most economical way , Realize the optimization of enterprise production process and business process , Guide enterprises to allocate resources reasonably 、 Identify potential benefit growth points or constraints , Adjust the production and operation plan in time , Make the production in the optimal operation state .

MES The main functional modules of the system include : Detailed scheduling of processes 、 Resource allocation and state management 、 Production unit allocation 、 Document management 、 Product tracking and product list management 、 Performance analysis 、 Labor resource management 、 Maintenance Management 、 Process management 、 Quality management 、 Data collection 、 Kanban management, etc .MES It can monitor the whole production process from raw materials entering the factory to products entering the warehouse , Record the materials used in the production process 、 equipment , The data and results of product testing and the production time of the product in each process 、 Personnel and other information . This information was collected through MES Systematic analysis , The production progress of the production site can be presented in real time through the system report 、 Goal achievement status 、 Product quality status , And the people who produce 、 machine 、 Utilization of materials , This makes the whole production site completely transparent .MES An important feature of the system is product traceability , It is of great significance for enterprise manufacturing process control and manufacturing process improvement .

By using MES The system can bring greater benefits to enterprise production management :

1、 utilize MES Advanced scheduling of the system , Planners can use graphical interfaces 、 Intuitively arrange each process of each part to the specific production equipment automatically , And the plan can be accurate to the specific processing of a certain process by a certain equipment within a certain period of time , Achieve the goal of lean organization production ; In the face of urgent orders , Planners can insert orders through the graphical interface , And we can see the impact of inserting orders on the whole plan in time .

2、 The team leader receives the production task directly through the on-site information management module , according to MES The planned processing task specified in the system scheduling instruction 、 Processing equipment 、 Start processing time 、 Dispatch workers to organize production at the time of processing completion , Avoid the randomness of production organization , Effective use of equipment resources .

3、 adopt MES Various production Kanban provided by the system , Realize the information sharing of the whole production process . The planning and scheduling can know the processing condition and production abnormality of each part on the production site at any time , It can grasp the production progress and deal with production exceptions in time .

4、 The system can automatically count customized production daily reports 、 Monthly report 、 Dispatch Express , Leader 、 Planner 、 The dispatcher can check the report at any time , Reduce a lot of statistical time , It also avoids human error , In time 、 accuracy 、 objective .

MES The system is close to the underlying equipment and control system , Convenient access to accurate real-time information , To make a detailed production plan and rescheduling .MES The implementation of the system in manufacturing enterprises not only adjusts the whole production process , And make the layout and data transmission of each production unit in the production process more reasonable 、 Orderly . adopt MES System implementation , Manufacturing enterprises reduce production lead time , Reduced WIP inventory , Improve the product quality , Ensure the rapid and accurate transmission of information . meanwhile , It also realizes the real-time visual management of the whole production process .

If you have MES/APS System related requirements , Pay attention to me , Get more details about smart manufacturing , Welcome to communicate !

边栏推荐

- Rainbow version 5.6 was released, adding a variety of installation methods and optimizing the topology operation experience

- Search for an element in a binary search tree (BST)

- Splunk子查询模糊匹配csv中字段值为*

- Open3D ISS关键点

- The legend about reading the configuration file under SRC

- 藏书馆App基于Rainbond实现云原生DevOps的实践

- Lua 编程学习笔记

- MES系统,是企业生产的必要选择

- 饥荒云服管理脚本

- Use of out covariance and in inversion in kotlin

猜你喜欢

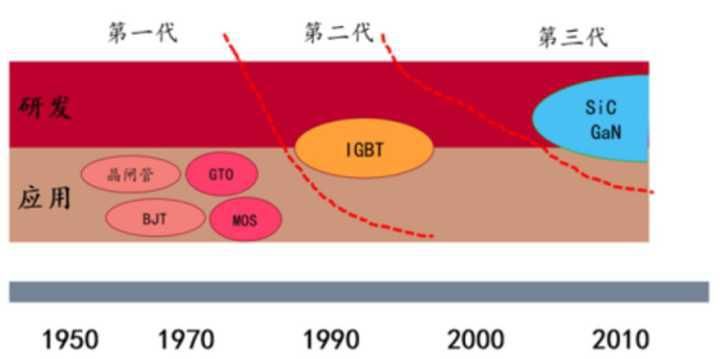

Battery and motor technology have received great attention, but electric control technology is rarely mentioned?

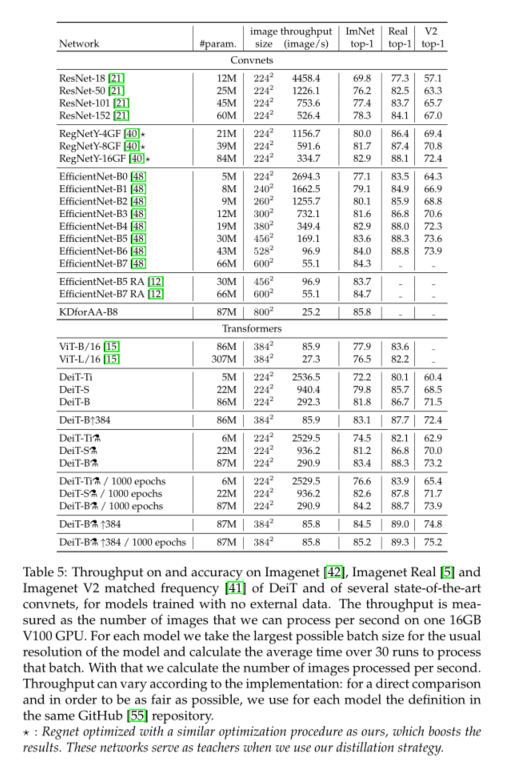

DeiT学习笔记

![[quick start of Digital IC Verification] 10. Verilog RTL design must know FIFO](/img/56/82f4533b5bded73df222ef65101a72.png)

[quick start of Digital IC Verification] 10. Verilog RTL design must know FIFO

柯基数据通过Rainbond完成云原生改造,实现离线持续交付客户

Application of slip ring of shipborne radar antenna

![[quick start of Digital IC Verification] 13. SystemVerilog interface and program learning](/img/d8/ffc1b7527f0269cecb2946ab402a2e.png)

[quick start of Digital IC Verification] 13. SystemVerilog interface and program learning

Explore creativity in steam art design

Myabtis_ Plus

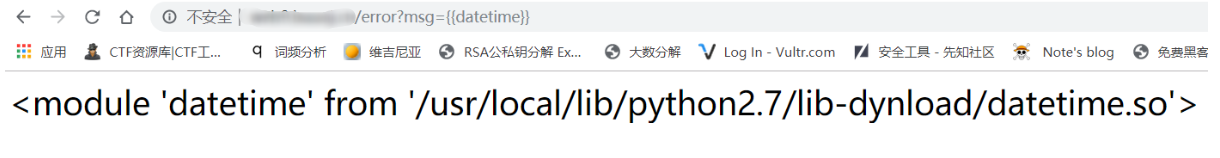

漏洞复现-easy_tornado

Quick analysis of Intranet penetration helps the foreign trade management industry cope with a variety of challenges

随机推荐

调用 pytorch API完成线性回归

[untitled]

船载雷达天线滑环的使用

利用 Helm 在各类 Kubernetes 中安装 Rainbond

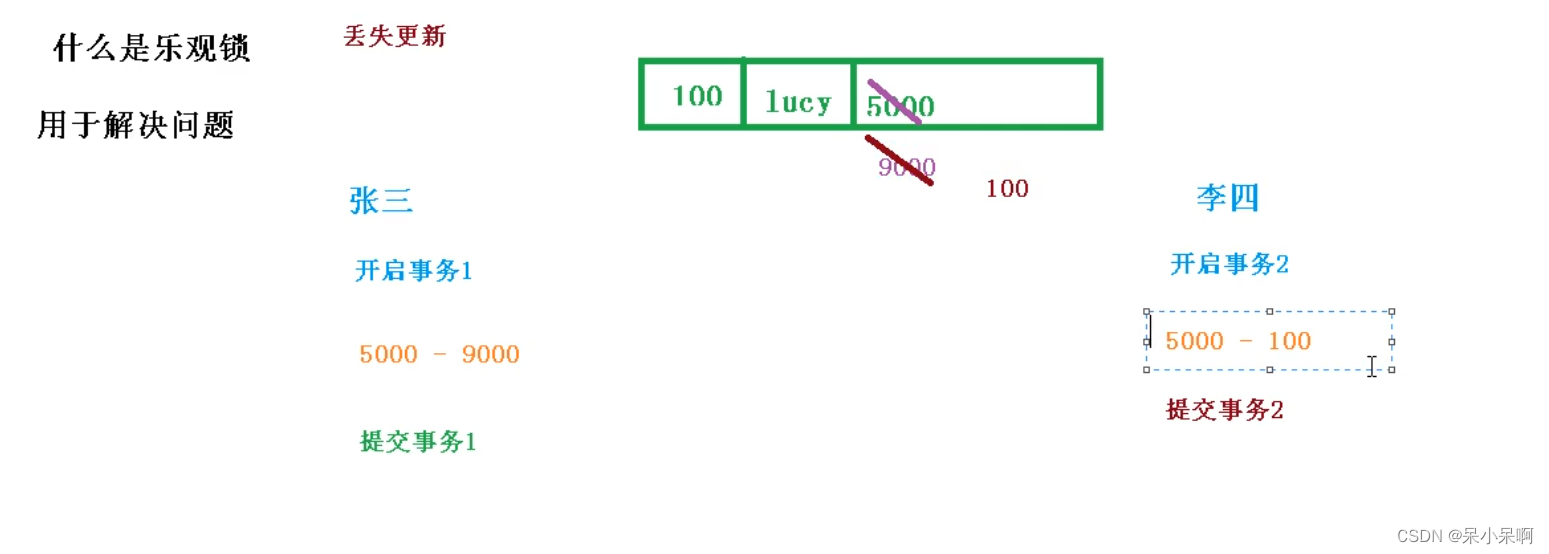

面试题(CAS)

积分商城管理系统中应包含的四大项

Explore creativity in steam art design

Qinglong panel -- finishing usable scripts

Make LIVELINK's initial pose consistent with that of the mobile capture actor

opencv学习笔记四——膨胀/腐蚀/开运算/闭运算

雅思考试自己的复习进度以及方法使用【日更版】

[IELTS speaking] Anna's oral learning records part2

Leetcode 187 Repeated DNA sequence (2022.07.06)

Blob object introduction

Easy to understand SSO

CTF-WEB shrine模板注入nmap的基本使用

Interactive book delivery - signed version of Oracle DBA work notes

复杂网络建模(三)

Introduction à l'objet blob

Rainbond结合NeuVector实践容器安全管理