当前位置:网站首页>Basic knowledge of lithium battery

Basic knowledge of lithium battery

2022-07-06 11:57:00 【FAE Laobing】

Basic knowledge of lithium battery

Objective record

One 、 front said

Two 、 Classification and performance index of lithium ion batteries

3、 ... and 、 The advantages and disadvantages of lithium-ion batteries

3.1 Advantages of lithium ion batteries

3.2 Disadvantages of lithium ion batteries

Four 、 How lithium ion batteries work

4.1 Working principle of lithium ion battery cell

4.2 Working principle of protection circuit

5、 ... and 、 The development direction of lithium ion batteries

One 、 front said

since 1958 In, a graduate student at the University of California proposed lithium 、 After the assumption of active metals such as sodium as battery cathode , People began to study lithium batteries . When lithium electrode is replaced by carbon material , That is, the industrial revolution of lithium-ion batteries began . The research of lithium-ion battery began from 1990 Japan Nagoura They developed petroleum coke as negative electrode , Lithium ion battery with lithium cobalt oxide as cathode ; Japan in the same year Sony And Canada Moli The two major battery companies announced that they would launch lithium-ion batteries with carbon as the negative pole . Compared with other rechargeable batteries , Lithium ion batteries have high voltage 、 Higher than energy 、 Long charge and discharge life 、 No memory effect 、 Little pollution to the environment 、 Quick charge 、 Low self discharge rate . As an important chemical battery , Lithium ion batteries are made by mobile phones 、 laptop 、 Batteries and submarines for digital cameras and portable small appliances 、 space flight 、 Batteries used in aviation , Gradually move towards the field of electric vehicles . With the increasingly serious global energy and environmental problems , Vehicles have switched to energy storage batteries as the main power source , Lithium ion batteries are considered high capacity 、 Ideal for high-power batteries .

Two 、 Classification and performance index of lithium ion batteries

Lithium ion batteries can be used in various fields , therefore , Its types are also diverse . According to the shape , At present, there are three main types of lithium-ion batteries on the market , Button type 、 Square and cylindrical , As shown in the figure below :

Cylindrical models use 5 Digit representation , The first two digits indicate the diameter , Third 、 Four digits indicate height .

for example :18650 Type a battery , Indicates that its diameter is 18mm, The height is 65mm. Square models use 6 Digit representation , The first two digits are the thickness of the battery , The middle two digits are the width of the battery , The last two digits are the length of the battery , for example 083448 type , Indicates that the thickness is 8mm, Width is 34mm, The length is 48mm.

According to the electrolyte form of lithium-ion battery , Lithium ion batteries include liquid lithium ion batteries and solid-state batteries ( Or dry ) There are two kinds of lithium-ion batteries . Solid state lithium ion battery is commonly known as polymer lithium ion battery , It is a new generation battery developed on the basis of liquid lithium ion battery , It has better safety performance than liquid lithium-ion battery , Liquid lithium-ion battery is commonly known as lithium-ion battery .

Battery dimensions 、 Weight is an important indicator of lithium-ion batteries , Directly affect the characteristics of the battery . The electrochemical characteristics of lithium-ion batteries mainly include the following aspects :

Rated voltage : The rated voltage of commercial lithium-ion batteries is generally 3.7V, The voltage range during operation is generally 4.2V~3.0V, There are also cases where the lower limit termination voltage is set to other values , Such as 3.1V.

Rated capacity : Means in accordance with 0.2C The capacity obtained when the constant current is discharged to the termination voltage .

1C Capacity : Means in accordance with 1C Capacity obtained from constant current discharge to termination voltage .1C The capacity is generally smaller than the rated capacity , The smaller the difference, the better the current characteristics of the battery , The stronger the load capacity .

High and low temperature performance : The high temperature of lithium-ion battery can reach +55℃, Low temperature can reach -20℃. Under this ambient temperature range , The battery capacity can reach the rated capacity 70% above .

Charge holding capacity : After the battery is fully charged, open the circuit and put it aside 28 God , And then according to 0.2C Percentage of the ratio of the capacity obtained by discharge to the rated capacity . The greater the numerical , It shows that the stronger its charge holding capacity , The smaller the self discharge rate . Generally, the charge retention capacity of lithium-ion batteries is 85% above .

Cycle life : With the lithium ion battery charging 、 discharge , The battery capacity is reduced to the rated capacity 70% when , The number of charge and discharge times obtained is called cycle life .

3、 ... and 、 The advantages and disadvantages of lithium-ion batteries

3.1 Advantages of lithium ion batteries :

① Large capacity 、 High working voltage . The capacity is twice that of the same nickel cadmium battery , It is more suitable for long-term communication ; The voltage of the usual single lithium-ion battery is 3.7V, It's nickel cadmium and nickel hydrogen batteries 3 times .

② Strong charge holding capacity , The allowable working temperature range is wide . stay (20±5)℃ Next , In an open circuit

Type storage 28 Days later , The normal temperature discharge capacity of the battery is greater than the rated capacity 85%. Lithium ion batteries have excellent high and low temperature discharge performance , Can be in -20℃~+55℃ Work , High temperature discharge performance is better than other kinds of electricity

pool .

③ Long cycle life . At present, domestic batteries are discharging continuously 300 Next time , The capacity of the battery is still not less than the rated capacity 80%, Far higher than other types of batteries , It has the economy of long-term use .

④ No environmental pollution . The battery does not contain cadmium 、 lead 、 Harmful substances such as mercury , It is a kind of clean “ green

color ” Chemical energy .

⑤ No memory effect . It can be recharged repeatedly at any time 、 Discharge use .

⑥ Small volume 、 Light weight 、 Higher than energy . Usually, the specific energy of lithium-ion battery can reach that of nickel cadmium battery 2 More than times , Compared with nickel metal hydride batteries with the same capacity , The volume can be reduced 30%, The weight can be reduced 50%, It is conducive to small and lightweight portable electronic devices .

3.2 Disadvantages of lithium ion batteries :

① The internal impedance of lithium-ion battery is high . Because the electrolyte of lithium-ion battery is organic solvent , Its conductivity is higher than that of nickel cadmium battery 、 The aqueous electrolyte of Ni MH battery is much lower , therefore , The internal impedance of lithium-ion battery is higher than that of nickel cadmium 、 Nickel metal hydride battery is about 11 times .

② The working voltage changes greatly . Discharge the battery to the rated capacity 80% when , The voltage change of nickel cadmium battery is very small ( about 20%), The voltage of lithium-ion battery changes greatly ( about 40%). For battery powered devices , This is a serious drawback , However, the discharge voltage of lithium-ion battery changes greatly , It is also easy to detect the remaining power of the battery .

③ The high cost , Mainly cathode materials LiCoO2 The price of raw materials is high .

④ There must be a special protection circuit , To prevent it from overcharging .

⑤ Poor compatibility with ordinary batteries , Due to the high working voltage , So the general case of ordinary batteries with three , Can be replaced by a lithium-ion battery .

Four 、 How lithium ion batteries work

What we usually call lithium-ion battery is the combination of lithium-ion battery cell and protective circuit , The working principles of lithium-ion cell and protection circuit are explained below :

4.1 Working principle of lithium ion battery cell :

Lithium ion cell is a device that converts chemical energy into electrical energy , Its cathode is generally lithium intercalation

matter , Such as LiCoO2、LiNiO2、LiMn2O4 etc. , Lithium is used as negative electrode - Carbon interlayer compound LixC6, Electrolyte is dissolved lithium salt ( Such as LiPF6、LiAsF6、LiClO4 etc. ) Organic solvents . The main solvent is vinyl carbonate (EC)、 Propylene carbonate (PC)、 Dimethyl carbonate (DMC) And chlorocarbonate (ClMC) etc. . During the charging process ,Li+ Back and forth between the two batteries , It's figuratively called “ Rocking chair batteries ”(rocking chair batteries, Abbreviation for RCB).

The total chemical reaction is :

LiMxOy+nC Li1-xMxOy+ LixCn

Lithium ion secondary cell is actually a lithium ion concentration cell , When charging ,Li+ Come out of the positive pole , It is embedded into the negative electrode through electrolyte , The negative electrode is in a lithium rich state , The positive electrode is in a lithium poor state , At the same time, the compensation charge of electrons is supplied to the carbon cathode from the external circuit , To ensure the balance of charge . When discharging, the opposite is true ,Li+ Come out of the negative pole , It is embedded into the cathode material through electrolyte , The positive electrode is in a lithium rich state . Take the lithium ion battery with lithium cobalt oxide as the positive pole as an example , When charging , Lithium ion from LiCoO2 Out of the cell , The ions in it Co3+ Oxidize to Co4+; When discharging , Lithium ions are embedded LiCoO2 In crystal cell , Among them

Co4+ become Co3+.

4.2 Working principle of protection circuit :

Due to the chemical properties of lithium ion batteries , In normal use , Its internal chemical reaction is the mutual conversion of electric energy and chemical energy , But under certain conditions , If it is overcharged 、 Over discharge and over current will cause side reactions inside the battery , After the side effect intensifies , It will seriously affect the performance and service life of the battery , And may produce a large amount of gas , The internal pressure of the battery increases rapidly and then explodes, resulting in safety problems , Therefore, all lithium-ion batteries need a protective circuit , For charging the battery 、 Effective monitoring of discharge state , And turn off the charging under certain conditions 、 Discharge the circuit to prevent damage to the battery .

The following figure shows the schematic diagram of a typical lithium ion battery protection circuit :

picture

As shown in the figure above , This protection is routed back to two MOSFET(V1、V2) And a control IC(U1) Add some resistance and capacitance elements . control IC Be responsible for monitoring battery voltage and loop current , And control two MOSFET Grid of ;MOSFET It acts as a switch in the circuit , It controls the on and off of the charging circuit and the discharging circuit respectively . The circuit has overcharge protection 、 Over discharge protection 、 Overcurrent protection and short circuit protection function , Its working principle is analyzed as follows :

a. The normal state :

Under normal conditions , In circuit U1 Of “CO” And “DO” Both pins output high level , Two MOSFET Are on , The battery can be charged and discharged freely . In order to effectively use the discharge current or charging current ,MOSFET Power tubes with low on resistance are used .

The diode in the figure is V1 and V2 Parasitic diode , Their existence enables the system to charge the battery in the over discharge state , It can discharge the load in the overcharge state .

b. Overcharge protection :

The charging mode required for lithium-ion batteries is constant current / Constant pressure mode , At the initial stage of charging, it is constant current charging , along with

With the continuous charging process , The battery voltage will rise to 4.2V, Then switch to constant voltage charging , Until the current gets smaller and smaller .

The battery is charging , If the charger circuit loses control , It will make the battery voltage exceed 4.2V Then continue to charge with constant current , At this time, the battery voltage will continue to rise , When the battery voltage is charged to more than 4.3V when , The chemical side reactions of the battery will intensify , May cause battery damage or safety problems .

In batteries with protective circuits , When control IC It is detected that the battery voltage reaches 4.28V( This value is controlled by IC decision , Different IC There are different values ) when , Its “CO” The pin will change from high level to low level , send V2 From on to off , Thus cutting off the charging circuit , The charger can no longer charge the battery , Play the role of overcharge protection . And now because of V2 The presence of the built-in bulk diode , The battery can discharge the external load through the diode . Under control IC The battery voltage is detected to exceed 4.28V To send off V2 Between the signals , There is still a delay ( The specific delay time is controlled by IC decision , Different IC There are different values ), To avoid misjudgment caused by interference .

c. Over discharge protection :

The battery is discharging to the external load , Its voltage will gradually decrease with the discharge process , When the battery voltage drops 2.7V when , Its capacity has been completely discharged , At this time, if the battery continues to discharge the load , It will cause permanent damage to the battery .

During battery discharge , When control IC The battery voltage is detected to be lower than 3.0V( This value is controlled by IC

decision , Different IC There are different values ) when , Its “DO” The pin will change from high level to low level , send

V1 From on to off , Thus, the discharge circuit is cut off , The battery can no longer discharge the load , Play the role of over discharge protection . And now because of V1 The presence of the built-in bulk diode , The charger can charge the battery through the diode .

Because the battery voltage cannot be reduced under the over discharge protection state , Therefore, the consumption current of the protection circuit is required to be very small , At this point, control IC It will enter the low-power state or sleep state , The power consumption of the whole protection circuit will be minimal ( The specific current consumption value is controlled by IC decision , Different IC There are different values ).

Under control IC The battery voltage is detected to be lower than 3.0V To send off V1 Between the signals , There is also a time delay ( The specific delay time is controlled by IC decision , Different IC There are different values ), To avoid misjudgment caused by interference .

d. Over current protection

Due to the chemical properties of lithium ion batteries , The battery manufacturer stipulates that the maximum discharge current shall not exceed 1.5C(C= Battery capacity / Hours ), When the battery exceeds 1.5C When the current discharges , It will cause permanent damage to the battery or safety problems .

During the normal discharge of the battery to the load , The discharge current is passing through the series 2 individual MOSFET when , because MOSFET On impedance of , A voltage will be generated at both ends , This voltage value U=I×RDS×2,RDS For a single MOSFET On impedance of , control IC Upper “VM” The pin detects the voltage value , If the load is abnormal for some reason , Increase the loop current , When the loop current is large enough to U>0.1V( This value is controlled by IC decision , Different IC There are different values ) when , Its “DO” The pin will change from high level to low level , send V1 From on to off , Thus, the discharge circuit is cut off , Make the current in the circuit zero , Play the role of overcurrent protection .

Under control IC Detect the occurrence of overcurrent and send out shutdown V1 Between the signals , There is also a time delay ( The specific delay time is controlled by IC decision , Different IC There are different values ), To avoid misjudgment caused by interference .

According to the above control process , The magnitude of its overcurrent detection value depends not only on the control IC Control value of , It also depends on MOSFET On impedance of , When MOSFET The greater the conduction impedance , For the same control IC, The smaller the overcurrent protection value .

e. Short circuit protection :

The battery is discharging the load , If the circuit current is large enough to U>0.9V( This value is controlled by IC decision , Different IC There are different values ) when , control IC Then it is judged as load short circuit , Its “DO” The pin will quickly change from high voltage to zero voltage , send V1 From on to off , So as to cut off the discharge circuit , Play the role of short-circuit protection . The delay time of short-circuit protection is very short , Usually less than 7 Microsecond . Its working principle is similar to overcurrent protection , Just different judgment methods , The protection delay time is also different .

The following table is a simple summary of the above principles :

picture

5、 ... and 、 The development direction of lithium ion batteries

Lithium ion battery as a typical representative of new energy , It has obvious advantages ,

But at the same time, there are some shortcomings that need to be improved . In recent years , Positive and negative active materials in lithium ion batteries 、 The research, development and application of functional electrolyte are quite active in the world , And has made great progress . in general , At present, the development of lithium-ion battery industry shows two trends : One 、 Polymer lithium ion batteries ( That is, the research and application of new electrolyte ); Two 、 New positive and negative active substances .

One 、 Polymer lithium ion batteries :

The so-called polymer lithium ion battery , It is at the positive pole 、 Among the three main structures of cathode and electrolyte , At least one or more batteries made of polymer materials . At present, polymer lithium-ion batteries in the whole industry have only changed the electrolyte , That is, the difference between polymer lithium-ion battery and liquid lithium-ion battery , Is to use polymer electrolyte ( Solid or gelatinous ). There is no polymer lithium-ion battery that really uses solid electrolyte in the industry , Japan Sony company ( Polymer lithium-ion battery industry ranks first ) Gel electrolyte is used .

Polymer lithium-ion batteries have many advantages : light 、 thin 、 Large capacity 、 Good safety performance 、 Shape can be arbitrary , therefore , The development of polymer lithium-ion batteries is relatively rapid , Especially in the field of high-capacity batteries , More reflect its advantages .

Two 、 New positive and negative active substances :

Because the packaging of polymer lithium-ion battery needs to occupy a relatively large size space , At present, the price of polymer lithium-ion batteries is on the high side , therefore , In small capacity batteries (≤1500mAh) field , Liquid lithium-ion batteries still dominate .

Research direction of liquid lithium ion battery , The key is to keep the volume unchanged , How to improve the capacity of the battery . At present, the whole industry is studying new positive and negative active substances .

Add a certain amount to the positive active material lithium cobalt oxide NCA(Lithium Nickel Cobalt AluminumOxide, Lithium nickel cobalt aluminum oxide ) Our products have begun mass production , The lithium ion battery using this active material is better than the lithium ion battery using only lithium cobalt oxide active material , Capacity can be increased 3% above .

With NCM(Lithium Nickel Cobalt Manganese Oxide, Lithium nickel cobalt manganese oxide ) Lithium ion battery as positive active material , With lithium cobaltate +NCM Lithium ion batteries as active substances , Mass production will also begin soon . Tests show that , The former is compared with the current lithium-ion battery , Capacity can be increased 6% above ; The capacity of the latter can be increased 10% above .

in addition , The research of negative active material is also in progress , With C+SiO As a negative active material, lithium-ion batteries will also be put into mass production , Change the situation that the cathode of lithium-ion battery adopts a single carbon material . It is worth mentioning that , With NCM As a positive active material 、 With C+SiO Lithium ion battery system as negative active material , Its minimum discharge voltage can be 2.5V( The current lithium-ion battery is discharged to 3.0V After that, there was basically no electricity ), In this way, the standby time can be relatively prolonged ( This is also supported by electronic components that can work at low voltage , That is to say 2.5V When , The whole system of electrical appliances such as mobile phones can be turned on and used normally , At present, the research of electronic components working at low voltage is also a hot direction , Because the voltage is low , The power consumption of components is also relatively reduced ).

边栏推荐

猜你喜欢

物联网系统框架学习

Redis interview questions

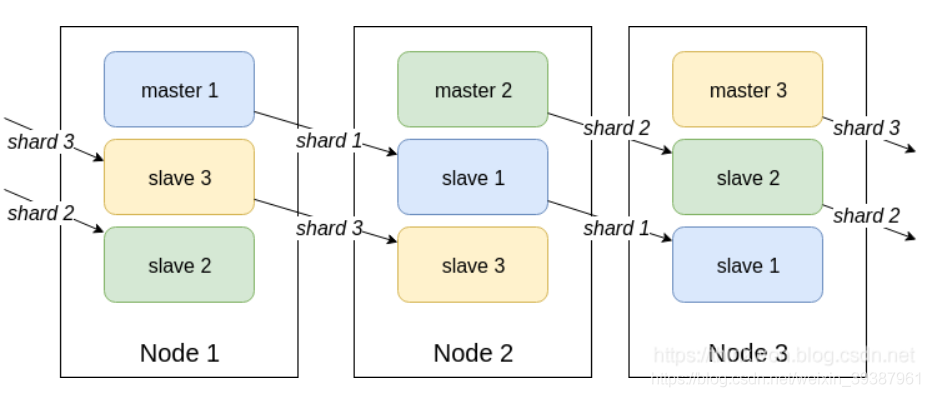

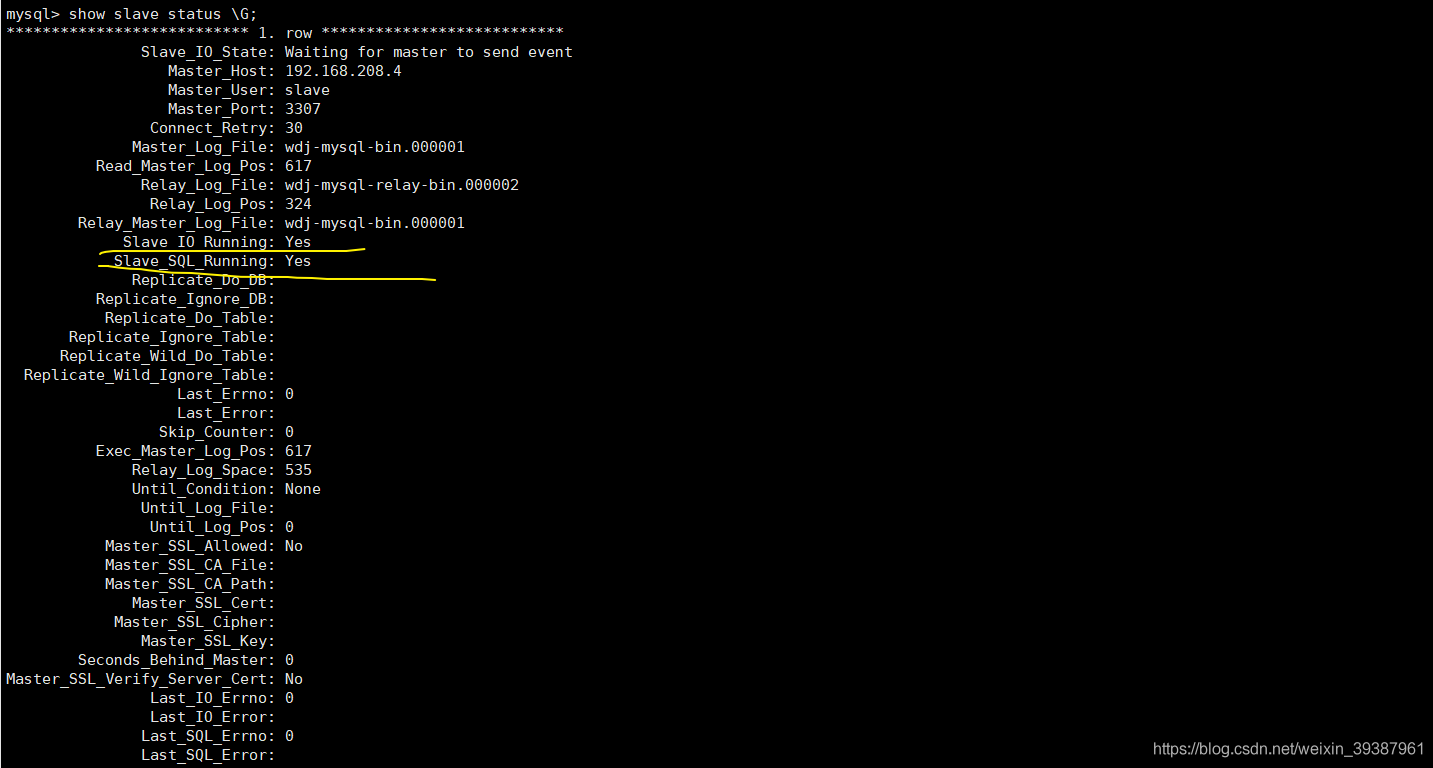

MySQL主从复制的原理以及实现

Come and walk into the JVM

2019 Tencent summer intern formal written examination

wangeditor富文本引用、表格使用问题

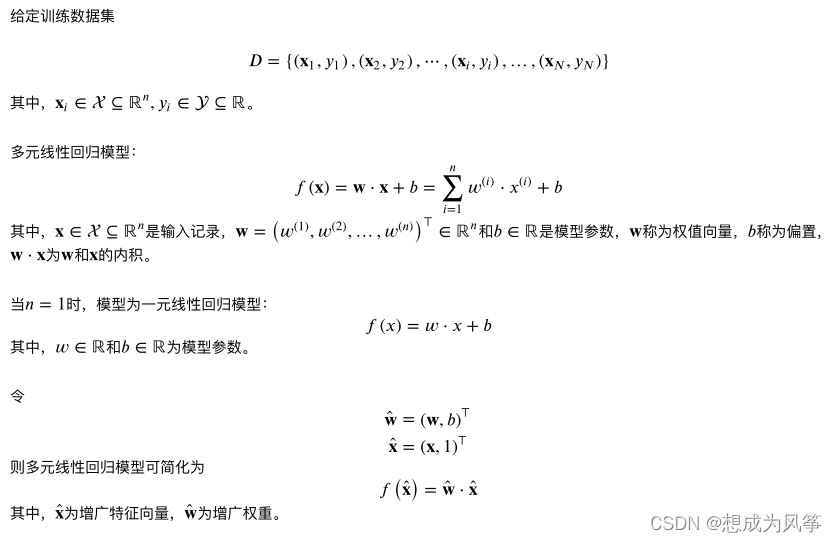

機器學習--線性回歸(sklearn)

![[yarn] CDP cluster yarn configuration capacity scheduler batch allocation](/img/85/0121478f8fc427d1200c5f060d5255.png)

[yarn] CDP cluster yarn configuration capacity scheduler batch allocation

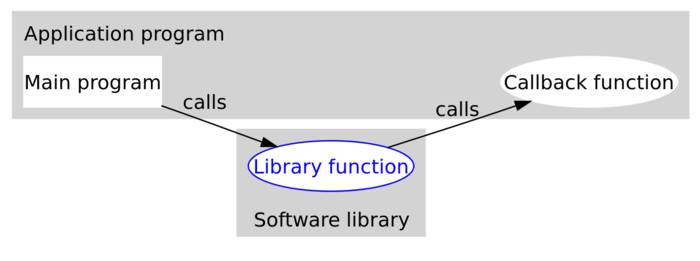

C语言回调函数【C语言】

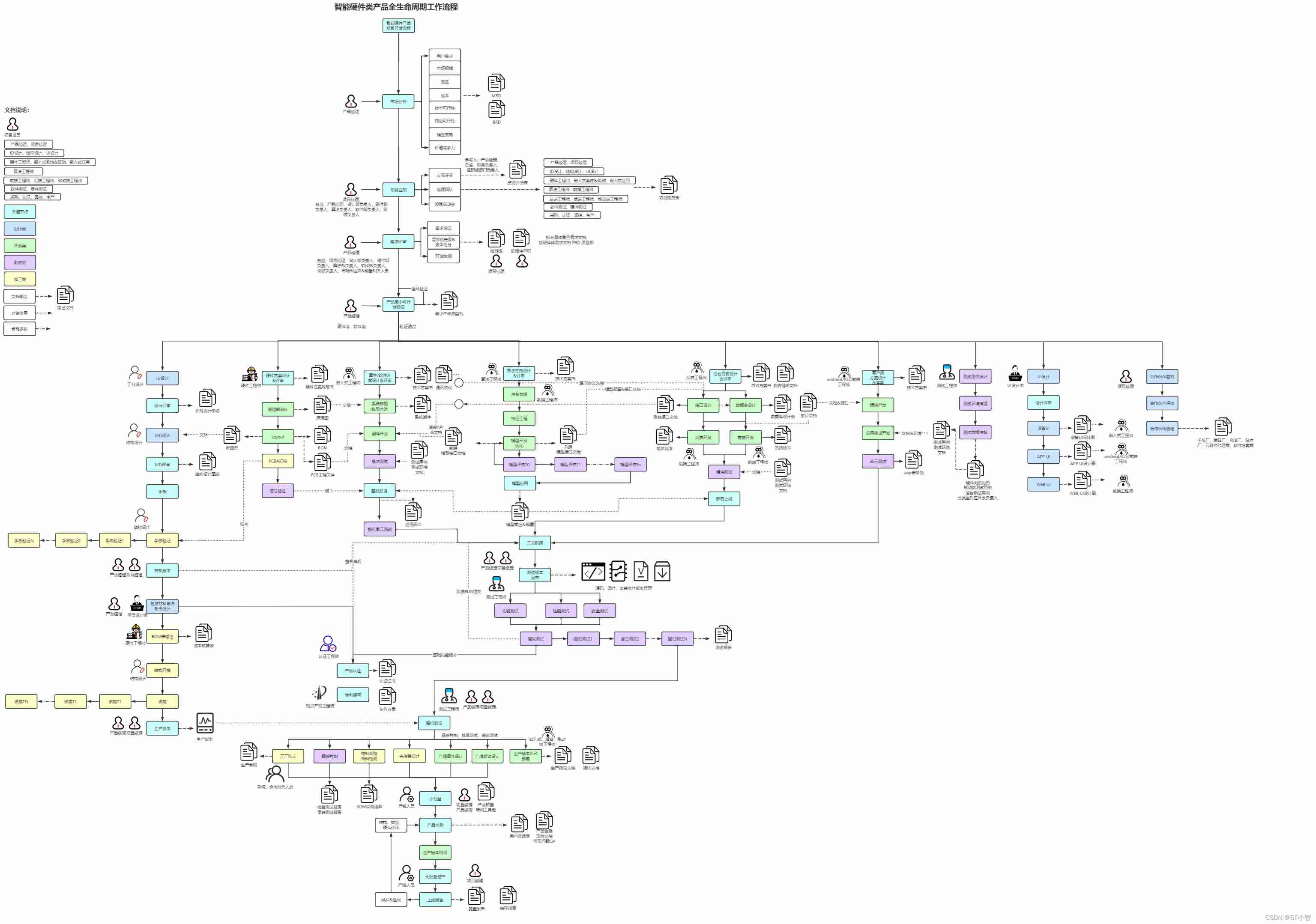

R & D thinking 01 ----- classic of embedded intelligent product development process

随机推荐

L2-001 emergency rescue (25 points)

数据库面试常问的一些概念

冒泡排序【C语言】

Detailed explanation of nodejs

PyTorch四种常用优化器测试

OPPO VOOC快充电路和协议

快来走进JVM吧

Apprentissage automatique - - régression linéaire (sklearn)

[Presto] Presto parameter configuration optimization

inline详细讲解【C语言】

express框架详解

互聯網協議詳解

5G工作原理详解(解释&图解)

There are three iPhone se 2022 models in the Eurasian Economic Commission database

Basic use of pytest

Hutool中那些常用的工具类和方法

荣耀Magic 3Pro 充电架构分析

Internet protocol details

MySQL realizes read-write separation

电商数据分析--用户行为分析