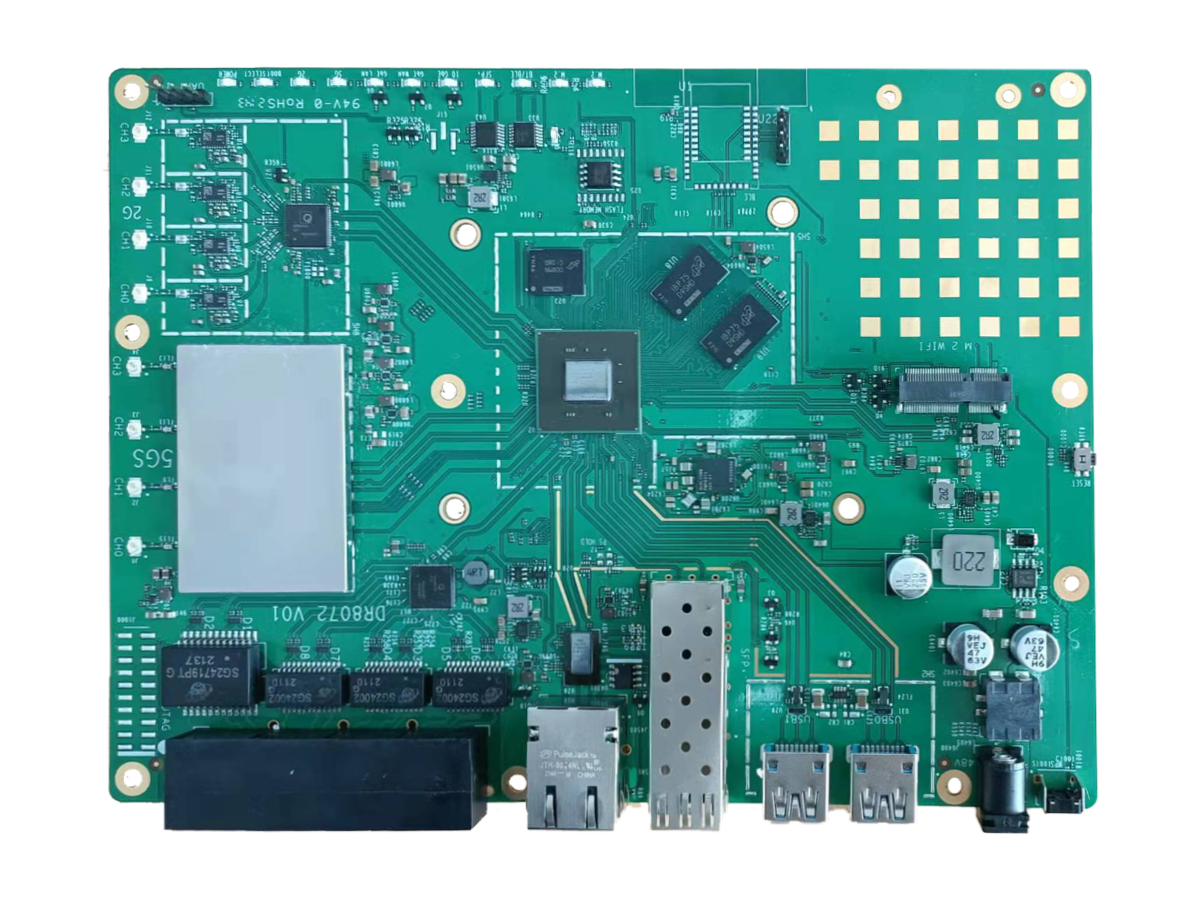

The overall height of the upper cylinder of the steel containment lifted this time is about 15 rice , The hoisting weight is about 720 Tons of , yes “ Linglong one ” The hoisting with the largest single weight of the project . The upper cylinder of the steel containment is made of 4 Layer total 32 Pieces are assembled , Factory manufacturing is adopted on site 、 Advanced construction mode of modular construction , Optimized the on-site construction logic , The on-site construction period is effectively saved , It creates conditions for the coordinated promotion of reactor civil structure and steel structure .

According to introducing , As the world's first pile , There is no experience to learn from in the construction of small pile demonstration projects . The project team focuses on high-quality and refined management , Strengthen the overall planning of the project , take “ Baton ” Project overall management mode , Decompose the task layer by layer , Pay close attention to the implementation , Ensure the upper cylinder assembly 、 Nondestructive testing and other work have been carried out steadily and orderly , Make the upper cylinder hoisting meet the conditions for hoisting in advance .

“ Linglong one ” It is the first in the world to pass the International Atomic Energy Agency IAEA Third generation modular small reactor for general design review . The project is on 2021 year 7 month 13 Official commencement , Planned total construction period 58 Months . Current nuclear island 、 The construction of the conventional island has been in full swing , At the peak of civil construction , Completed 5 A first level milestone node , The project construction is progressing smoothly . As a multifunctional modular small reactor developed by CNNC and with independent intellectual property rights , It has high security 、 The emergency scope is small 、 A wide range of uses 、 The plant site has strong adaptability and other characteristics . CNNC will continue to resolutely implement the Party Central Committee 、 Decisions and arrangements of the state council , complete 、 accuracy 、 Fully implement the new development concept , Effectively coordinate development and security , insist “ Two increases, one control and three improvements ” Unshakable goal , To stabilize the economy 、 Make greater contributions to the steady and healthy development of economy and society .

It is reported that , Shandong nuclear equipment manufacturing plant 、 China Nuclear Engineering Corporation 、 China Nuclear Power Consulting Corporation 、 China Nuclear Industry Second Construction Co., Ltd 、 China Nuclear Machinery Co., Ltd. and other participating units cooperate efficiently , Eight maritime administrations coordinate to ensure , Make the upper cylinder hoisting meet the conditions for hoisting in advance .

Extended reading

“ Linglong one ” The world's first steel containment vessel consists of top heads 、 Upper cylinder 、 The lower cylinder and the bottom head together form , Bearing the integrity and sealing function of the reactor building , It is an important safety barrier of reactor . In the course of construction , The installation of the steel containment upper cylinder ring lifting rail beam is the key and difficult point of this assembly , The ring lifting rail beam is divided into 12 block , Gross weight 120 tons , High precision is required , Welding is difficult . Hainan nuclear power small reactor project team optimized the welding logic , Take measures such as cold air supply to optimize the on-site welding environment , Strengthen the process control of welding quality , Successfully complete the welding of ring bearing beam , Complete the set work objectives ahead of schedule .

( Photo photography : Liu Xuan )

![110. Network security penetration test - [privilege promotion 8] - [windows sqlserver xp_cmdshell stored procedure authorization]](/img/62/1ec8885aaa2d4dca0e764b73a1e2df.png)