当前位置:网站首页>RGB LED infinite mirror controlled by Arduino

RGB LED infinite mirror controlled by Arduino

2022-07-05 06:01:00 【acktomas】

Arduino The control of the RGB LED Infinite mirror

2013 year 9 month 17 Daily update : Thank you Arduino competition Everyone who voted for this project in ( I am ten “ The second prize ” One of the winners )! If you want to use addressable LED Try this project with a light bar instead of a simulated light bar , Please check out Rainbow Jar project ( It's also Arduino The winner of the competition ).

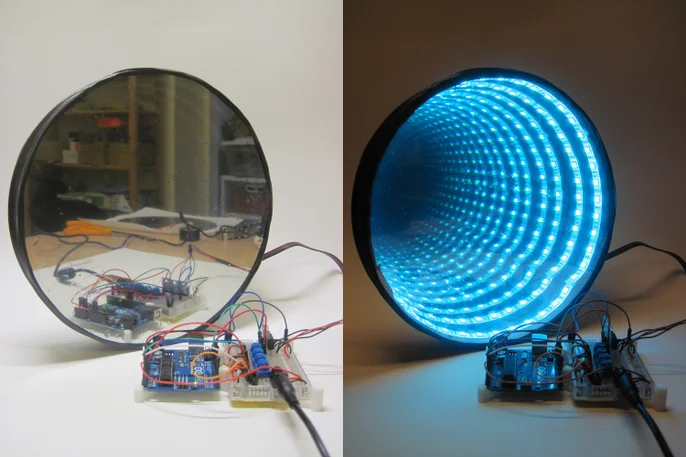

This is my combination of two classic projects : Use Arduino Of RGB LED Control and infinite mirrors . It's a RGB LED Infinite mirror , It allows you to switch between fading mode with adjustable speed and direct control mode , You can set red separately 、 Green and blue LED Brightness level . The main inspiration for this particular project comes from This infinite mirror Instructable and Adafruit Of RGB LED Light bar tutorial , But there are more high-quality resources in these two projects .

If you like , You can make a very simple 、 Cheap infinity mirror ( Just in Instructables Mid search “Infinity Mirror”, You will find some ), Or spend hundreds of dollars crazily ( If not thousands of dollars )( stay YouTube On the search “infinity mirror table”, You will understand ).

material : Electronic products,

2016 year 2 Monthly update :Jameco Electronics A kit containing all electronic materials for the project is now available . Please note that , This kit does not Include The material used to build the frame , So you still need to buy these materials separately ( See below ). As on this page Described at the bottom , I earn commission by selling this kit .

With mini breadboard and jumper Arduino UNO R3..

( Optional ):Arduino/ Bread board support . stay Thingiverse Found on This Cool simple design .

[1 rice RGB LED Light Bar .SparkFun With one Numbers RGB LED The lamp strip , The light bar has individually addressable LED( If you want to send one to the light bar at a time LED Light pulse , Or there are other modes ). Both strips can be cut to fit the length of your mirror .

four 10K Potentiometer .

Three N Ditch MOSFET.

22 AWG Connecting line ( black ). Like to use red and black respectively V+ Color code the ground connection . It can be downloaded from SparkFun get Smaller 25 Feet roll .

22 AWG Connecting line ( Red ). Same as the notes above , Scroll here smaller .

12V/5A DC power supply . I use RGB LED The light bar needs 12V, according to [ Data sheet ](https://www.sparkfun.com/datasheets/Components/LED/FLB6 5060RGB(300) Waterproof FLEX STRIP.pdf), Every 3-LED paragraph ( The smallest unit that the light bar can be cut into ) Consume 60mA. therefore , In the whole lamp with 60 individual LED when , The absolute maximum value under full brightness is 1.2A. I have one 12V The charger .

Adafruit and SparkFun Both have smaller 、 Cheaper 12V Power Supply ( Respectively 1A and 600mA), According to the size of the mirror and how many it will use LED, It may well meet your needs .

material : Build a mirror

important : Building this mirror requires three main parts : Ordinary mirror 、 Frame and one-way mirror . First , If you can find a cardboard / A pulp cover and an ordinary mirror that fits snugly inside , That's the simplest —— The parts I bought don't fit together perfectly , So I have to use a solution ( See step 6). secondly , According to the tools available to you , Cutting acrylic can be painful , So please plan accordingly ( See step 9 and 10).

About LED There is another important consideration for the light bar , It cannot be cut to any length - It must be cut into 3-LED Multiple of segment , The length is less than 2 Inch - So you want Inside perimeter Your frame is a multiple of that length . therefore , I will link to the components I use to build the mirror , But you can still follow these instructions to build mirrors of different sizes or shapes .

- 9" Diameter round mirror . I bought this set [7 A mirror , The aim is to make some smaller infinite mirrors .

- 8 Inch 、9 Inches and 10 Inch diameter circular carton . important Yes. - I bought these in the hope 9 An inch diameter mirror can cling to 9 Inch lid or inside the box itself ( Because I can't ’ You can't find a separate box for sale on Amazon ). It has no .9" The lid of is too small , and 10" Your box is too big . therefore , I put 9" The top of the lid was cut off . , And only use rims . If you skip and view page 6 Picture in step , This will make sense . The key is , Ideally , You should use a mirror close to the pulp cover or box .

- 1/8" thick 12"x12" Transparent acrylic ( organic glass ) plate . Available for purchase . If you can use a laser cutting machine , Acrylic is very easy to cut . I don't have , So I try to use puzzles ( The first 9 Step ) And scoring ( The first 10 Step ). Both work quite well , But it will cause some jagged edges , In hindsight , rectangular Mirrors are better than round mirrors . If you want to make a slightly smaller mirror ,McMaster sell Pre cut 6" Diameter circle . I didn't shop around for bigger pre cut circles , But you may find them .

- Mirror window film . I order from Amazon [ These things .

- Black paint . I bought a can of ordinary black spray paint .

- Optional : If you want to be very fancy , You can order a custom size one-way mirror , Instead of sticking the window reflective film on a piece of plexiglass . This may provide you with higher optical quality in your final product .

Tools

- Soldering iron . I have a [ One from SparkFun Variable temperature .SparkFun The product page says “ You need to weld on your own wire .” But when my strip arrived, all four wires had been welded . even so , take ( Stranding ) Pushing the end of the line into the bread board can be painful , Therefore, I suggest welding on small solid wires to make it easier .

- Lead free solder .

- Wire stripper , If you don't have a pair to peel 22 AWG Wire stripper . Again , if necessary , You can squeeze through without these , But I bet most people who read this article have wire cutters .

- Mini needle nose pliers , If you are as clumsy as I am and hate to handle tiny bread board components with your fingers .

- Electric drill ( See the first 6 Step —— You may only need a sharp knife to escape )

- seccotine

- Electrical tape

See? ? It's time to start building !

The first 1 Step : How infinite mirrors work ?

Okay , almost It's time to start building . First , I want to pre empt another common comment : How these things actually work ?

Not surprisingly , There is no magic . The secret is , The infinity mirror actually contains two different transmissivity and Reflectance mirror . For all practical intentions and purposes , The mirrors we deal with in our daily life are 100% The reflection of the ( Technically speaking , A small amount of light will also Absorbed , But we can ignore this for the time being ). This is an infinite mirror “ Back ” Regular mirror ( On the left side of the above figure ). However , Colored window film ( On the right side of the figure above ) Only about half of the light is reflected *. It means , When you will LED Caught between two mirrors , some Light will escape through the front mirror and enter your eyes . The rest bounce back from the rearview mirror , Then enter the front mirror again , This process continues to infinity - Hence the name . however , Because a little light escapes every time , Every continuous illusion you see LED It looks a little darker , Until they gradually disappear - you actually You can't see infinite LED.

Please note that , this It doesn't work , Because the window tone “ Only light is allowed to pass in one direction ”, This is a common misunderstanding . In order to make the illusion work properly , The side of the front mirror where the observer is ( The outside world ) Must have LED One side of ( Infinite mirror ) Much darker . This is with you in the crime drama / The effect seen in the movie is the same , Someone was locked up in an interrogation room , There is a mirror on the wall , But someone on the other side of the mirror observed , It seems that it is just a window . Only when the interrogation room is well lit , When the observation room is dark , this only It works .

* Reflectivity / The exact percentage of transmittance may vary depending on the type of product you purchase - Different levels of reflectivity and transmittance are actually regulated in different states , For windows , If you are curious , Please Google .

Add tips, questions, comments, downloads

step 2: Build the circuit

Before building the image , It's best to build 、 Test and debug the circuit . otherwise , If you get a beautiful , Fancy mirrors are just to throw away the switch and find something doesn't work , That would be very sad . therefore , First let's assemble the circuit and test LED Light Bar . If you are not familiar with the circuit and do not understand what happened , You can (a) Follow the instructions blindly , perhaps (b) Look forward to the next step to explain the working principle of the circuit .

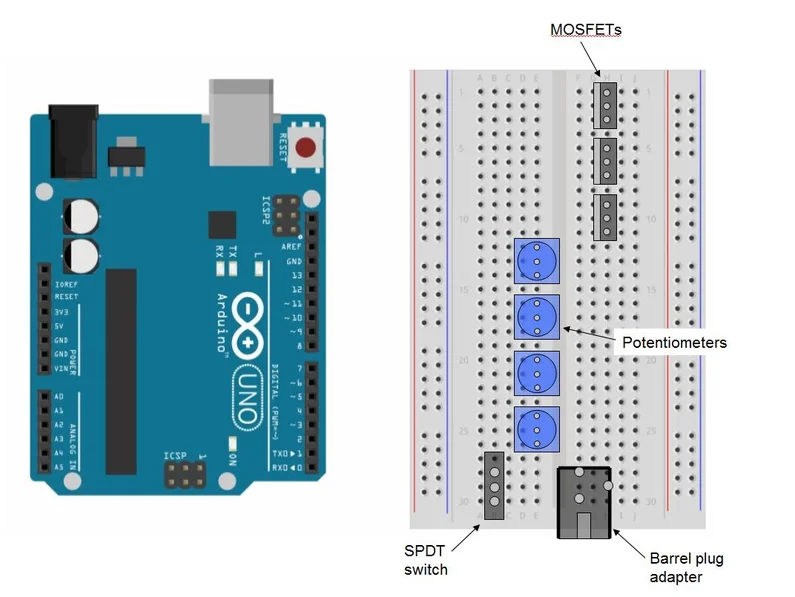

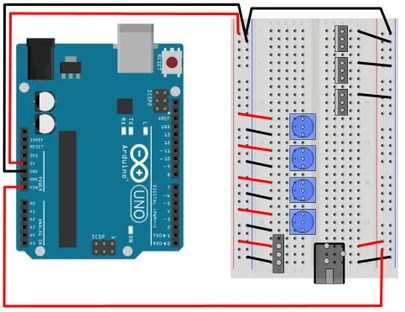

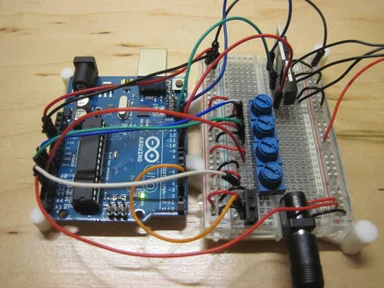

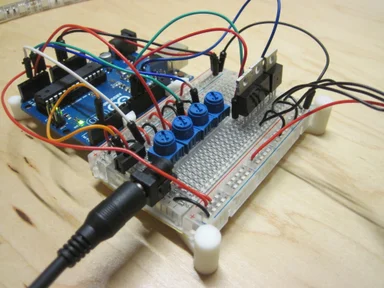

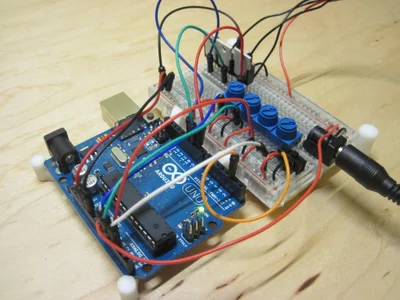

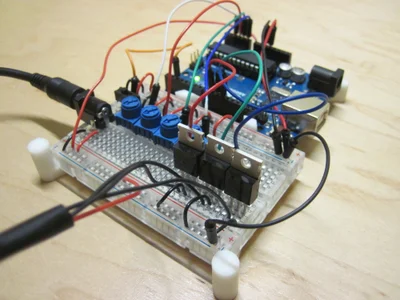

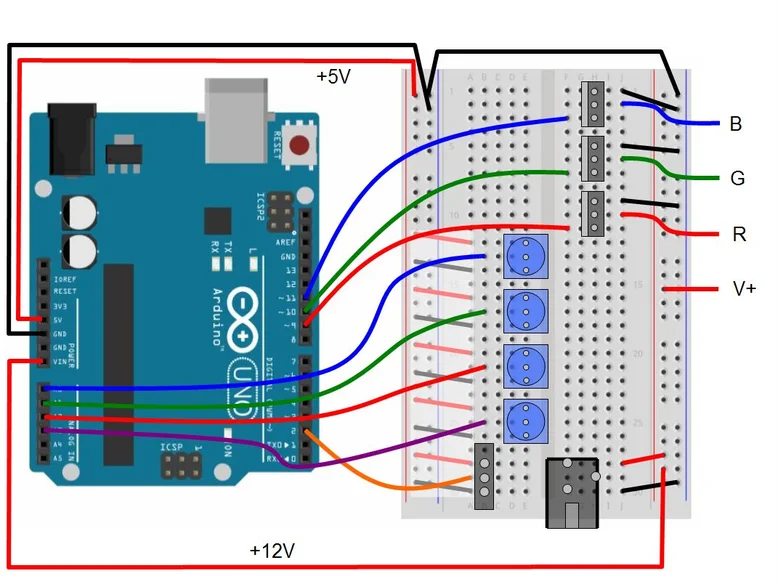

If you have experience in using test boards , Then the circuit can be assembled according to the third test board diagram above or directly from the circuit diagram . For novice , I divide it into three steps , Hope to make things less overwhelming - Corresponding to the first three charts above :

1) With three MOSFET, Four potentiometers ,SPDT Switch and barrel jack adapter fill bread board . I make these parts in the above figure “ transparent ”, So that you can see exactly the position of their pins *.

2) Add wires to connect to the power and ground rails . Here I color code these with red and black , But remember , If you only have a multicolor patch cord kit and no red and black connectors , You can use any color you want . Please note that *, One of them How to connect the guide rail of the test board from the barrel Jack to +12V Power Supply ( adopt Vin Feed the power supply to Arduino), The other is connected to Arduino Of +5V Power pin , But they share one Common ground *. Whatever you do , Do not short circuit at the same time +12V and +5V Power Supply !

3) Add wires to connect to Arduino Input and output of , And to connect to LED Wire of light bar ( If your light strip has pre welded wires , Please use these wires )**. Again , I'm here for their respective red , Green and blue wires are color coded , But your ability to do this will depend on the wires available .

* I started in Fritzing Make this picture in , But yes MOSFET And potentiometers and other components are frustrated by the large amount of space they occupy in the breadboard view mode ( They provide quasi 3D View instead of “ From top to bottom ” View , So it takes up much more space than in real life , And cover up other things on the bread board ). therefore , I intercepted Arduino Screenshot of bread board , And in Powerpoint They are drawn in .

** If your LED The light strip does have pre welded wires , Please be careful with the color coding .SparkFun The product page of indicates , The blue and green wires are switched , This can be annoying , But it won't cause any harm . My light belt has a connection to V + Of black Line , stay LED Reversing polarity on the light strip may be bad news . I think I understand that I don't want to use two red lines ( One for V+, One for red LED), But I hope they use something other than black to express V +.

Add tips, questions, comments, downloads

step 3: How the circuit works ?

This is a rough explanation of how the circuit works and the purpose of the component . Experienced people can skip this step , But if you're curious , Please read on . I don't have time to write a whole introductory chapter on circuits , So I try to provide relevant links when possible .

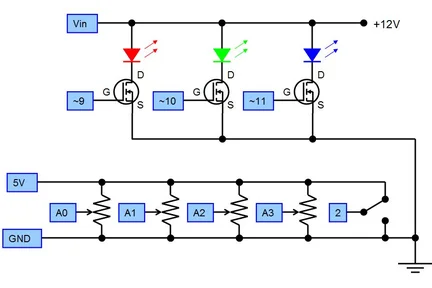

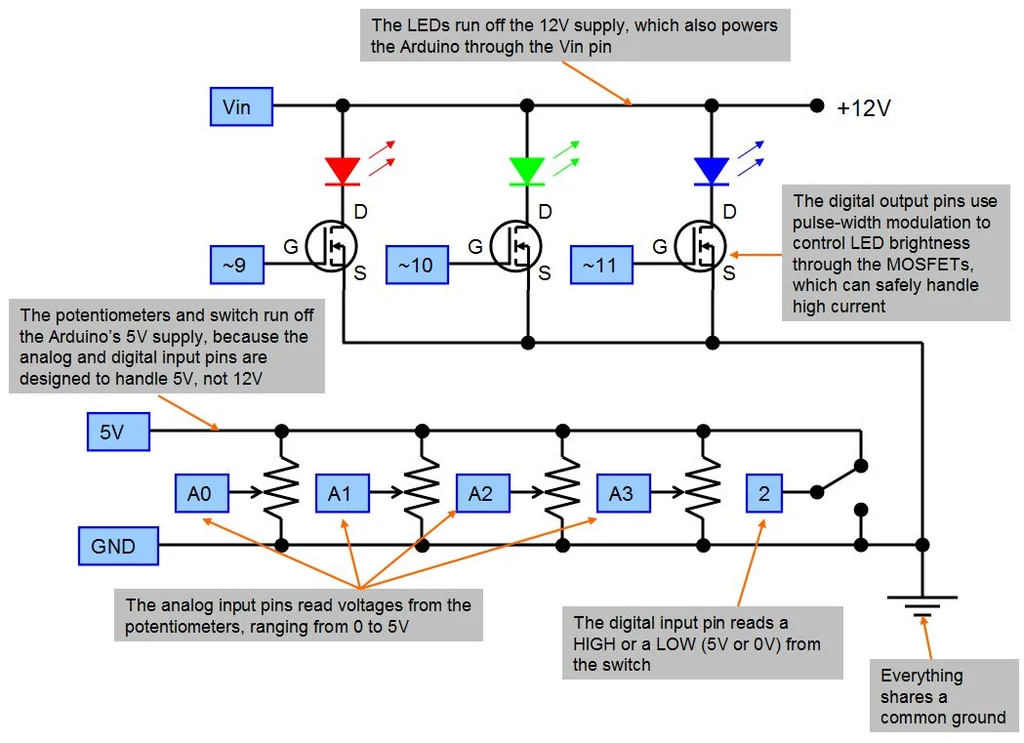

Barrel jack adapter Provide +12V Power Supply . This is for LED Necessary for power supply of light bar , And also through its Vin Pin for Arduino Power supply *.* Technically speaking ,Arduino The built-in barrel plug of will accept +12V Power Supply , Then you can go through Vin Pin accesses the power supply , however LED It will consume a lot of current - More than you want to pass Arduino Current of board operation . such , The current will “ split ”——Arduino Only absorb what it needs , The high current enters directly through the test board LED. Special thanks Adafruit Support Forum Help me solve this problem .

SPDT switch Just a switch , Used to select where the program is located “ Pattern ”. The details of the code will be explained in the next step , But in essence, it is only rotating through different colors “ fade ” Switch between mode and direct control mode , You can control a single red , Green and blue LED brightness . The middle pin of the switch is connected to Arduino One of the digital input pins of , Two external pins are connected to +5V And ground . therefore , According to the turning mode of the switch , Program usage digitalRead() Function read Numbers High or low and work accordingly ( Be careful :SPDT representative “ SPDT ”, Wikipedia page about switches There is a good form , Different types of switches are summarized , With charts ).

** Potentiometer ** It's you “ control ” Of , It depends on which mode the program is in . In independent control mode , Three potentiometers control red 、 Green and blue LED The brightness of . In fade mode , A single potentiometer controls the rate of fading . The potentiometer has three pins . Same as switch , One pin is connected to +5V, One pin is connected to ground . However , Different from the switch , Rotating the potentiometer will make the voltage on the middle pin be 0V and 5V Between continuity change , Not just switching between the two . therefore , The middle pin of the potentiometer is connected to Arduino Of simulation Input . then , Use analogRead() function ,Arduino Convert this voltage into 0 To 1023 Number between , In order to use ( Please refer to the next step ).

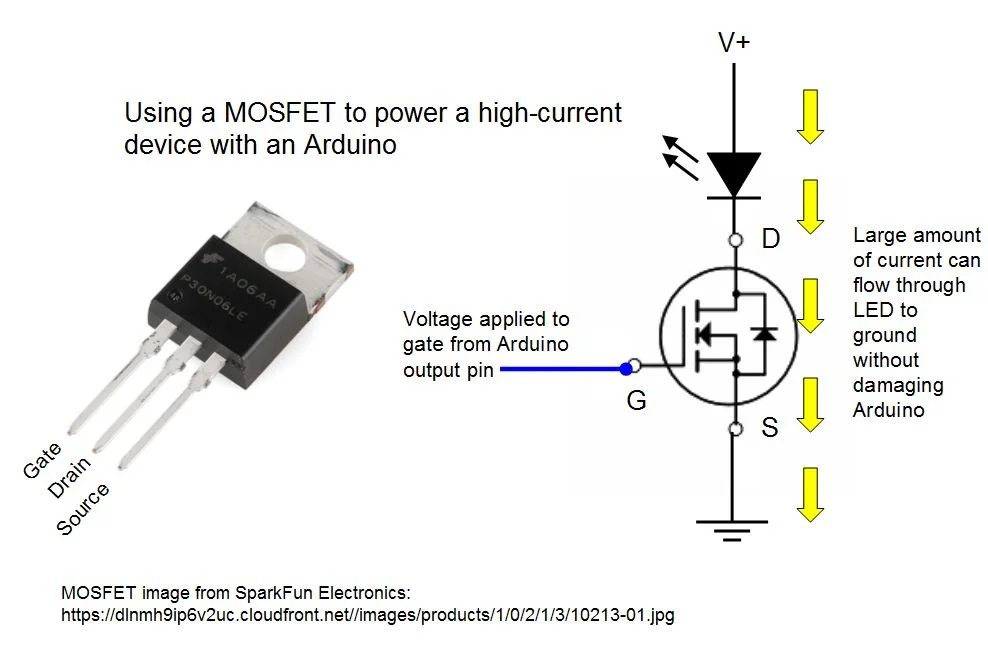

MOSFET It may be the hardest part for beginners in electronics to understand . These are the drivers “ high power ” equipment ( Such as motor , Solenoids and LED Light Bar ) Necessary , These devices usually need to be better than Arduino The current that can be provided is more current . On Wikipedia The pages about these are actually quite dense , So I will try to give a simplified explanation here .MOSFET There are three pins , be called “ Grid ”(G)、“ Drain electrode ”(D) and “ Source pole ”(S). In the simplest form ,MOSFET Like a valve , Let the current flow from the drain to the source .“ gate ” Control this valve ( Think about opening and closing a valve into the garden hose ), Except that control is electric Not mechanical . from Arduino The voltage applied to the gate by an output pin of the makes MOSFET“ open ” - Allow high current to flow from drain to source , No need Actual from Arduino Absorb any current . If from Arduino The voltage to the grid is zero ,MOSFET Will turn off and block the current flow . In this way , You can use a small Arduino Control huge motors and lights , As long as you have an external power supply large enough to handle it .

I should also mention Pulse width modulation (PWM). This is a method for using Arduino control LED Common techniques of brightness . In short ,Arduino The output pin of is Numbers Of , Therefore, they can only output high level or low level (5V or 0V). They cannot be adjusted by continuously changing the voltage LED Brightness or motor speed . contrary , What they can do is send out very fast pulses (Arduino About per second 500 Time ), Much faster than human eyes can see . Each pulse consists of a HIGH Paragraph and a LOW Section composition , The relative ratio between the two determines what we actually see “ brightness ”.0% Gao He 100% Low pulses look like “ close ”.100% Gao He 0% Low will be “ Full brightness ”,50% high /50% Low will be about half brightness . You see. . In this circuit ,PWM The signal is sent to MOSFET, then MOSFET Control passed LED High current of , So as to achieve “ Decline ” Effect and adjustable brightness .

step 4:Arduino Code

The following Arduino Copy and paste the code into the new sketch . I won't write my own tutorial here , So if you don't know how to create / Upload sketches , Please check the official Arduino - introduction page .

Be careful : This may not be the most effective code ! especially , I'm not sure if there is a better way to continuously monitor the fading rate potentiometer , Instead of copying and pasting the same line of code over and over again , Or if there is a way to break through when turning the switch for loop ( Now? , If you switch to personal control mode in fade mode , Before completing the current fade in and fade out cycle , No switching ). therefore , I'll throw it there , As a challenge to anyone who is reading this article and wants to release better code . obviously , I am essentially a mechanical engineer , Not a programmer .

// Arduino code to control and RGB LED strip

// Uses a toggle switch to switch between color-fade mode

// and individual RGB control mode

// adapted from http://learn.adafruit.com/rgb-led-strips/example-code

const int RED = 9; // define digital output pins for individual red,

const int GREEN = 10; //green and blue channels

const int BLUE = 11;

const int POT1 = 0; // define analog input pins for three potentiometers

const int POT2 = 1;

const int POT3 = 2;

const int POT4 = 3;

const int BUTTON = 2; // define digital input pin for the switch

int val = 0; // stores the state of the switch input pin

int FADESPEED = 0; // initiate fade speed set by potentiometer

int r = 0; // initialize the red, green and blue values

int g = 0;

int b = 0;

void setup() {

pinMode(RED, OUTPUT); // define digital pins as outputs and inputs as needed

pinMode(GREEN, OUTPUT);

pinMode(BLUE, OUTPUT);

pinMode(BUTTON, INPUT);

}

void loop() {

val = digitalRead(BUTTON); // read the input value from the toggle switch

if (val == HIGH) {

// code for RGB color fade

/**

By starting from the 4 A potentiometer reads the analog input to set the fade in and fade out speed

analogRead A value between 0 and 1023 Number between , And in milliseconds “ Delay ”,

So the maximum delay you will get here is about 1/10 second . Divide by different numbers to change the maximum fade in and fade out time .

*/

FADESPEED = analogRead(POT4) / 10; // set the fade speed by reading analog input from 4th potentiometer

// analogRead will output a number between 0 and 1023, and "delay"

// is in milliseconds, so the biggest delay you'll get here is about

// 1/10 of a second. Divide by a different number to change the max

// fade time.

// fade from blue to violet

for (r = 0; r < 256; r++) {

analogWrite(RED, r);

/**

Keep checking the fade in and fade out speed , otherwise , It will not be updated until a complete cycle is completed . Maybe not the most effective way ...

FADESPEED = analogRead(POT4) / 10; // check the fade speed continuously, otherwise

// it won't update until it's gone through a complete cycle.

// Probably not the most efficient way to do this...

delay(FADESPEED);

}

// fade from violet to red

for (b = 255; b > 0; b--) {

analogWrite(BLUE, b);

FADESPEED = analogRead(POT4) / 10;

delay(FADESPEED);

}

// fade from red to yellow

for (g = 0; g < 256; g++) {

analogWrite(GREEN, g);

FADESPEED = analogRead(POT4) / 10;

delay(FADESPEED);

}

// fade from yellow to green

for (r = 255; r > 0; r--) {

analogWrite(RED, r);

FADESPEED = analogRead(POT4) / 10;

delay(FADESPEED);

}

// fade from green to teal

for (b = 0; b < 256; b++) {

analogWrite(BLUE, b);

FADESPEED = analogRead(POT4) / 10;

delay(FADESPEED);

}

// fade from teal to blue

for (g = 255; g > 0; g--) {

analogWrite(GREEN, g);

FADESPEED = analogRead(POT4) / 10;

delay(FADESPEED);

}

}

else {

// code for individual RGB control with potentiometers

r = analogRead(POT3) / 4; // read values from the 3 potentiometers and divide by 4 to set brightness

g = analogRead(POT2) / 4; // note that analog read is 10-bit (0-1023), analog write is an 8-bit PWM

b = analogRead(POT1) / 4; // signal so you need to divide this value by 4.

analogWrite(RED, r); // write analog values to red, green and blue output pins

analogWrite(GREEN, g);

analogWrite(BLUE, b);

}

}

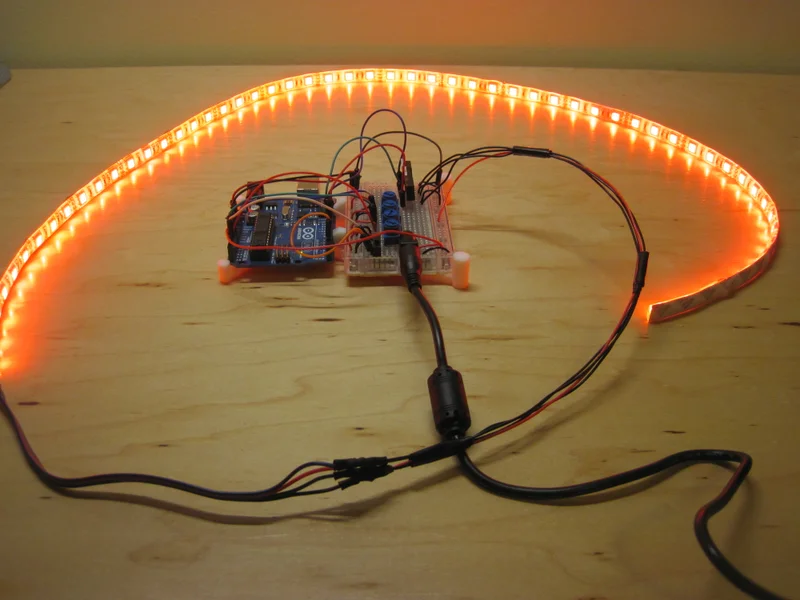

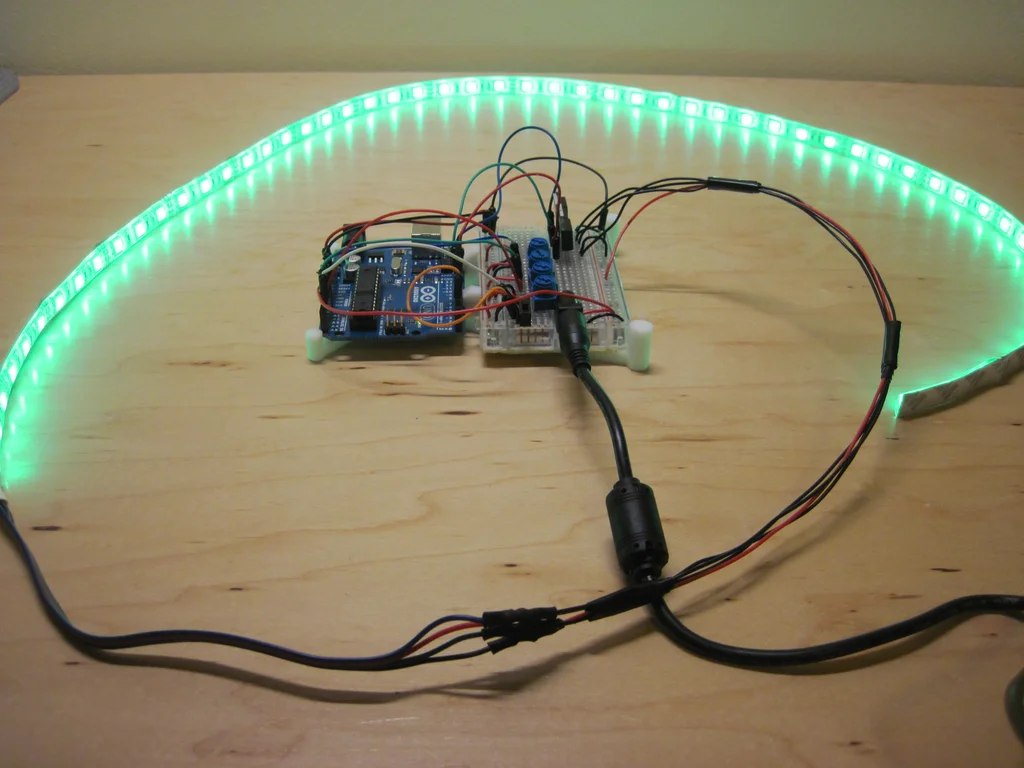

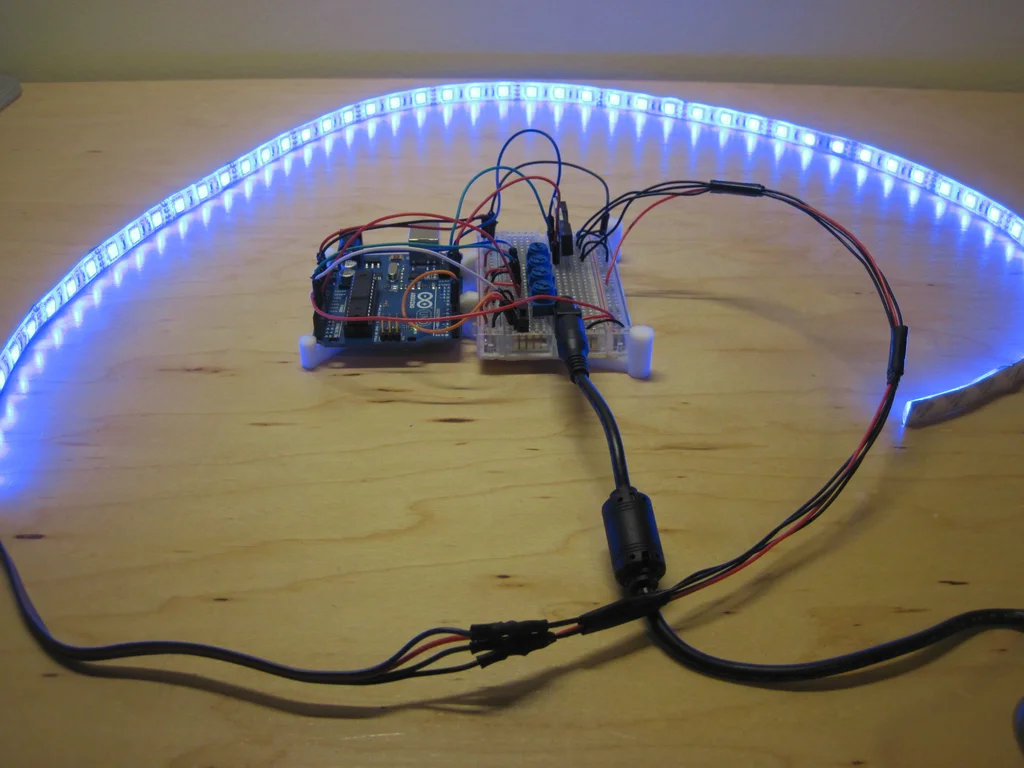

step 5: Test circuit 、 Code and LED Lamp with

Plug the power supply into the barrel jack adapter , stay Arduino It takes a second to start , You should be able to control the light ! Use the toggle switch to switch between the two modes . In one mode , You can use the first three potentiometers to directly control red 、 green 、 LAN San Road LED brightness ; And combine them to make different colors . In another mode ,LED Will fade automatically between colors , But you can use the fourth potentiometer to control the fading rate .

Watch this video to demonstrate , If it doesn't work , Please refer to the troubleshooting tips below . Please note that , There are several places in this video , my LED flashing - This must mean when I put Arduino When pushing around , I have a loose connection or two exposed wires collide with each other somewhere . watch out .

Troubleshooting tips

- Check your test board connection . Just a wire placed in the wrong position can stop the whole thing from working .

- Ensure that I/O The pin matches the pin actually used . If you copy and paste my code directly , This should not be a problem , But there is no harm in checking .

- Make sure your LED The light bar works normally . take LED Light bar V+ The wire is directly connected to the... On the test board +12V Power rail , Then insert the respective wires into the ground rail , Test red 、 Green and blue .LED The lamp strip has a built-in resistor , So you don't have to worry about blowing it out . If each color lights up , Then your light bar is ok , And the problem lies elsewhere in the circuit .

- Use routine LED Test circuits and codes **, skip MOSFET**. If MOSFET A little too new and confusing , You can make an introductory version of this project , Use only three ordinary old LED, Or a RGB LED( Search for SparkFun or Adafruit And other common suppliers , There are many options ). These are low current and low voltage , Enough to make them directly from Arduino drive , Unwanted MOSFET, however You will need a current limiting resistor , In order to LED It won't burn .LED Flickering and fading are very common starts Arduino project , So I won't reproduce the direction here .

- Skip potentiometer , Use hard coded color pattern to test the circuit . This allows you to ensure PWM Signals and MOSFET Normal work , Don't worry about analog inputs and potentiometers .

You may have noticed a trend here - The general idea is to put your circuit ( Or code ) Decompose into smaller ones that can be tested separately , Isolated part . This allows you to narrow down , Search for problems in a partitioned way , Instead of just staring at a huge circuit and messy code , Want to know what's wrong .

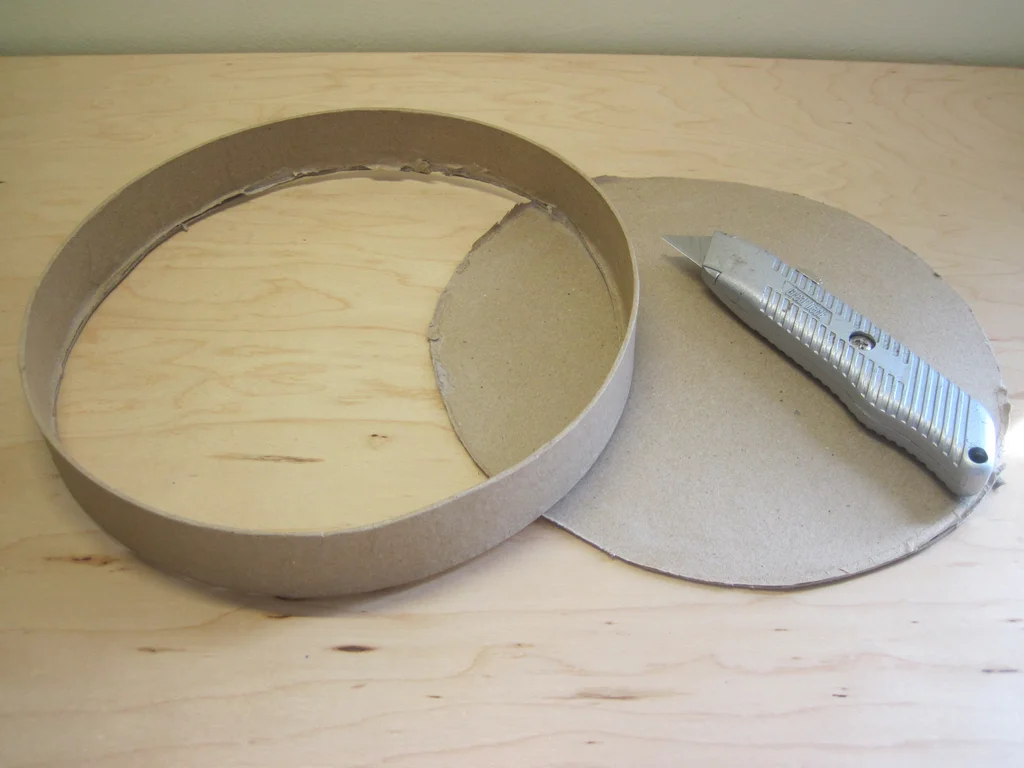

step 6: Prepare the frame

therefore , I am what I am hope my 9 Inch diameter mirror can cling to me 9 Inch diameter lid or box itself . It can be seen from the picture above ,10 Inch diameter boxes and lids are too big . My solution is to cut 9 Inch cap top , Then use only cylinders . I kept the round part cut from the top , To strengthen the back of the mirror . therefore :

1) Carefully cut off the top of the cardboard cover with a knife .

2) Paint the two pieces with the color you choose . I believe if the inside of the edge is black , Then the vision will be better , External is not important .

3) Drill a large enough hole on the side of the contour , send LED The wires on the lamp belt can pass through . In hindsight , I should drill first , Then draw .

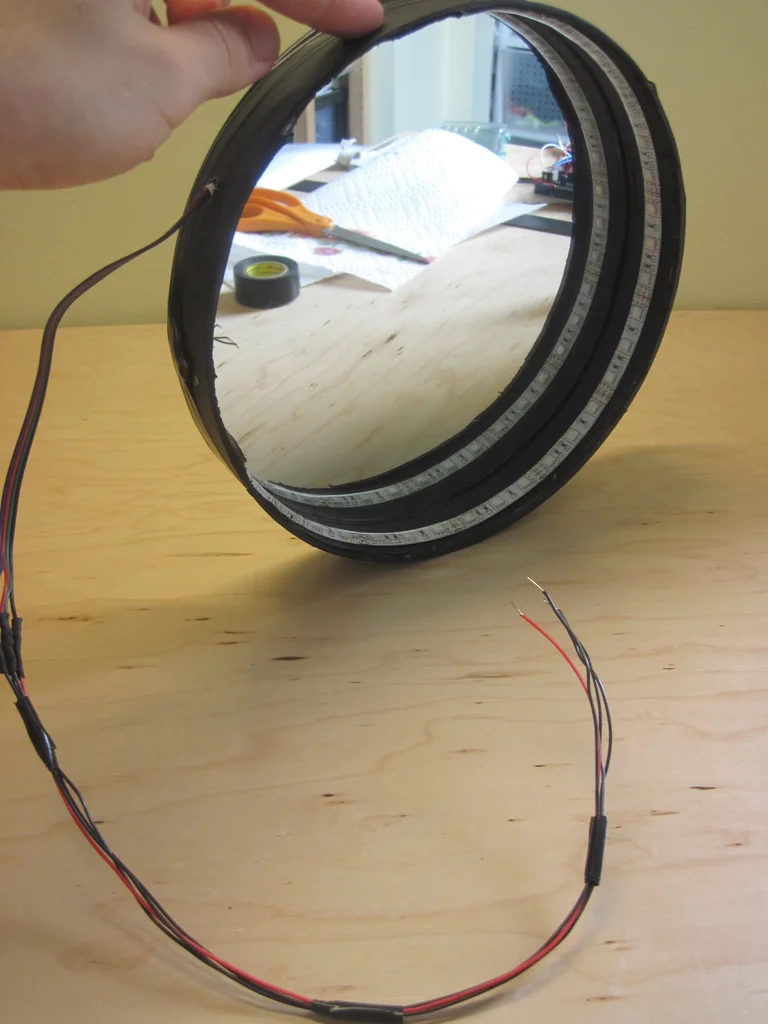

step 7: install LED Light Bar

take LED The light ribbon goes through the hole you drilled in the cardboard cover .

Start carefully from LED Remove the adhesive tape backing from the light strip , Then press it firmly on the inside or on the cover . Make sure it is centered in the cylinder .

Once you have completely determined the length of the light band , Just cut it off LED Lamp with . Important note :LED You can't just cut anywhere - You must cut it into 3 individual LED paragraph , And you can see the cutting line with the marking pad . If you cut anywhere else , Then the last few of the light bar LED Will not work properly .

You must also want the perimeter of the cover to match these 3-LED Multiple of segment length ( about 1 15/16) Well matched , Otherwise you may be in the first and last LED There is a gap or a little overlap between .

step 8: Assemble the frame

There are small hooks on the back of the mirror I bought , When I take it off the package 9 Inch mirror , I accidentally pulled the hook off the package . therefore , It could be a good thing , I didn't try to hang it on the wall with it . in any case , This can be solved , because You need to Take off the hook , So that the mirror can be placed flat inside the frame .

I used to glue the back of the mirror to the flat of the cardboard cover ( Not painted ) part . Now may be a good time to make sure your mirror is clean and free of fingerprint stains , Because any defect will diminish the illusion in the finished product . From then on , I use paper towels to deal with / Pick up the mirror , To avoid leaving extra fingerprints around the edges .

Stick the mirror on the cardboard circle , I just use electrical tape LED The light strip is wrapped around the outer edge of the rim , And connect it to the mirror ( Of course , Tape can also , But I hope it's black ). Again , This is just a circuitous process that I have to go through , Because my mirror didn't fit the lid at the beginning .

Once you have everything safe , start-up Arduino And ensure that it is not damaged in some way in this process LED Light strips or wires may be a good idea .

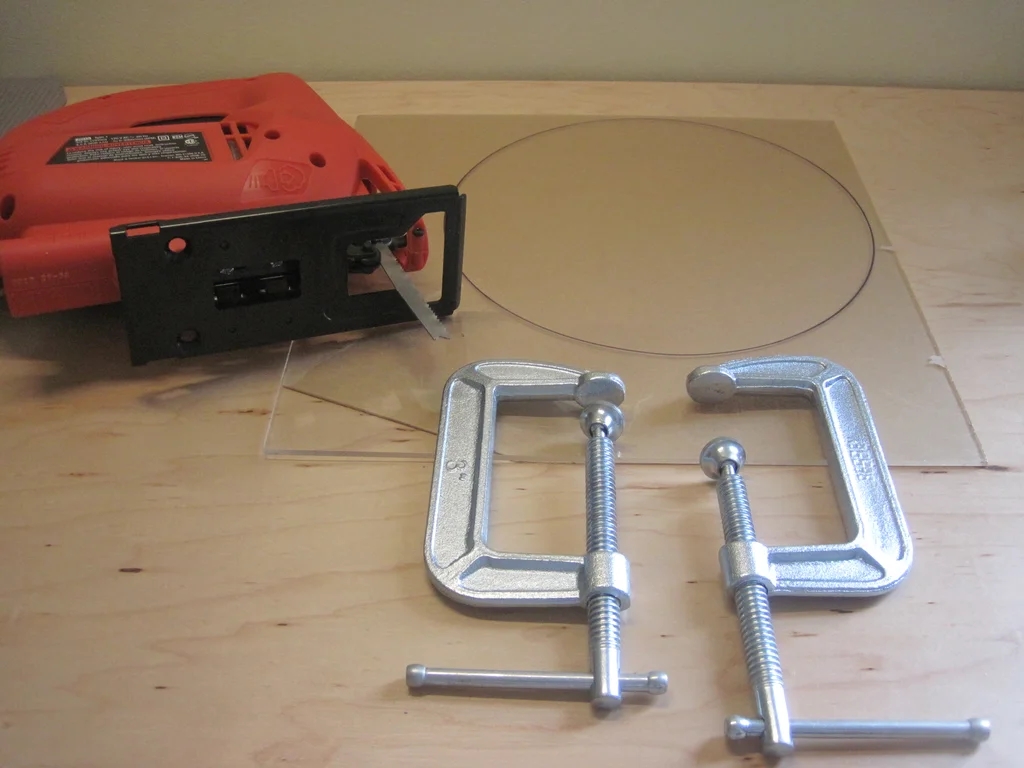

step 9: Cutting acrylic - Puzzle

Thank you for your participation To this forum post The idea of people .

Continue with the previous important safety information : If you use a laser , Acrylic smoke is bad for you . If you are cutting / Sawing / polishing / Whatever , You don't want to breathe dust . Make sure to work in a well ventilated place , And wear appropriate masks when necessary .

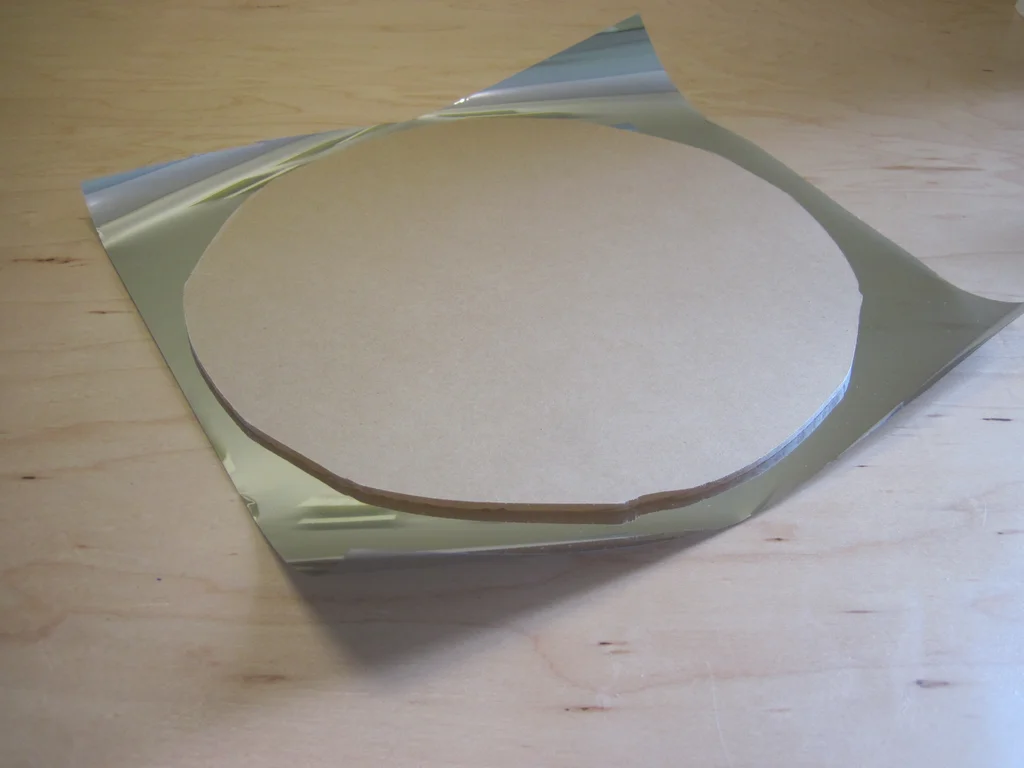

therefore , Through the puzzle : I will 9 The outline of the inch mirror is traced on the acrylic paper backing . then , I use two C Type a clip secures it to the edge of the table , Then roughly cut off the corners , Make an octagon . then , I made smaller cuts continuously along this line . The end result is not Too much too bad - There are some cracks around the edge , But there is no catastrophic fracture to destroy the circle .

Some safety precautions - First I tried this with a wooden blade , It doesn't work at all , Cause some big , The serrated acrylic sheet breaks when the blade is stuck . Bought a thinner metal blade at the hardware store , The effect is much better . The edges are still sharp , So I just polish them by hand to avoid cutting . As usual , Electric tool , I suggest using safety glasses to complete this step .

Add tips, questions, comments, downloads

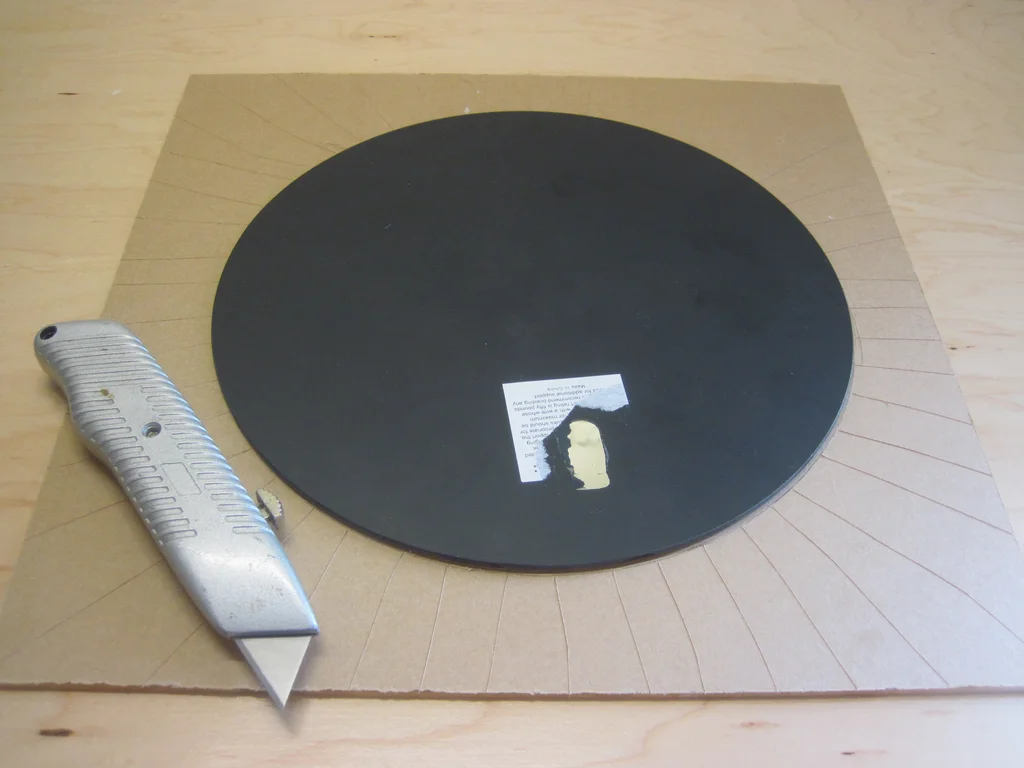

step 10: Cutting acrylic - Scratch and catch

Another way I cut acrylic acid is to draw a circular outline with an art knife , Then draw a bunch of additional radial lines , I hope I can break a single fragment , Finally, leave a circle in the middle .

I First of all Try this for the first time , I use C Type a clip clamps acrylic on the edge of the table , Then hit the separated fragments with a mallet . It doesn't work , Cause the block to break within the circumference of the circle ( however , If you are making a rectangular mirror , This is good for straight cutting ).

Next , I started from Forum post Got some useful suggestions : I rated acrylic acid , Then put it in the refrigerator for a few hours *.* Then I use... Again C Clip , But hold the edge with a vise and break , Instead of hitting it with a mallet . It works very well , There are fewer cracks around the edges than the jigsaw method . It still has some sharp points sticking out , I polish it down .

To be fair , I have never tried to use a vise clamp without freezing first , Or use a mallet after freezing - So I can't 100% Determine whether the vise clamp or freezing makes it work better for the second time .

Add tips, questions, comments, downloads

step 11: Apply mirror tone

At this point , We assume that you have somehow managed to cut the acrylic into the right size . Before proceeding , Please make sure to wipe / Clean acrylic ( Fingerprint stains , Grinding dust, etc ).

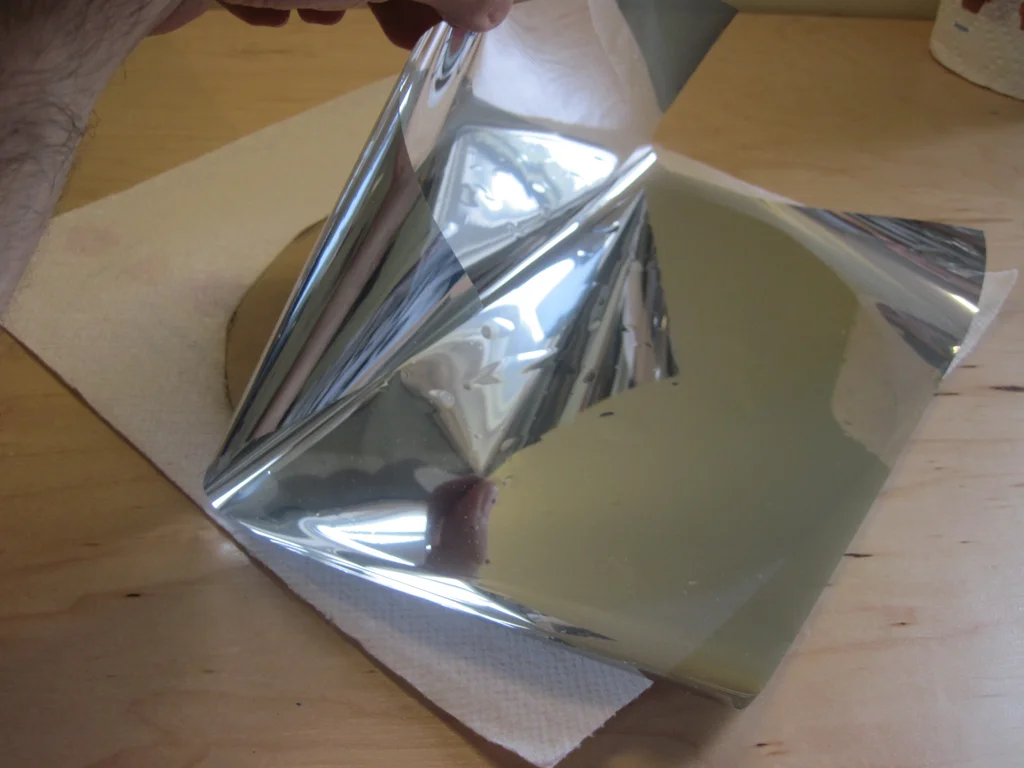

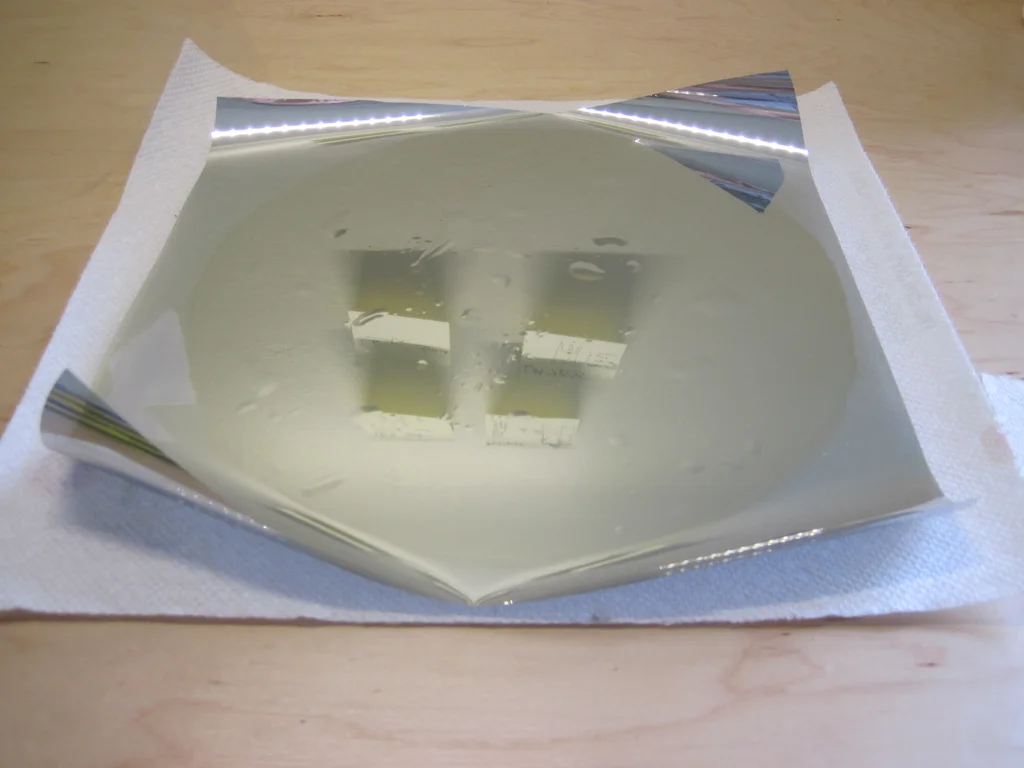

Next , You need to cut a piece more than acrylic Bigger Mirror tone - This means that you can deal with extra material on the edges , Don't worry about fingerprint stains .

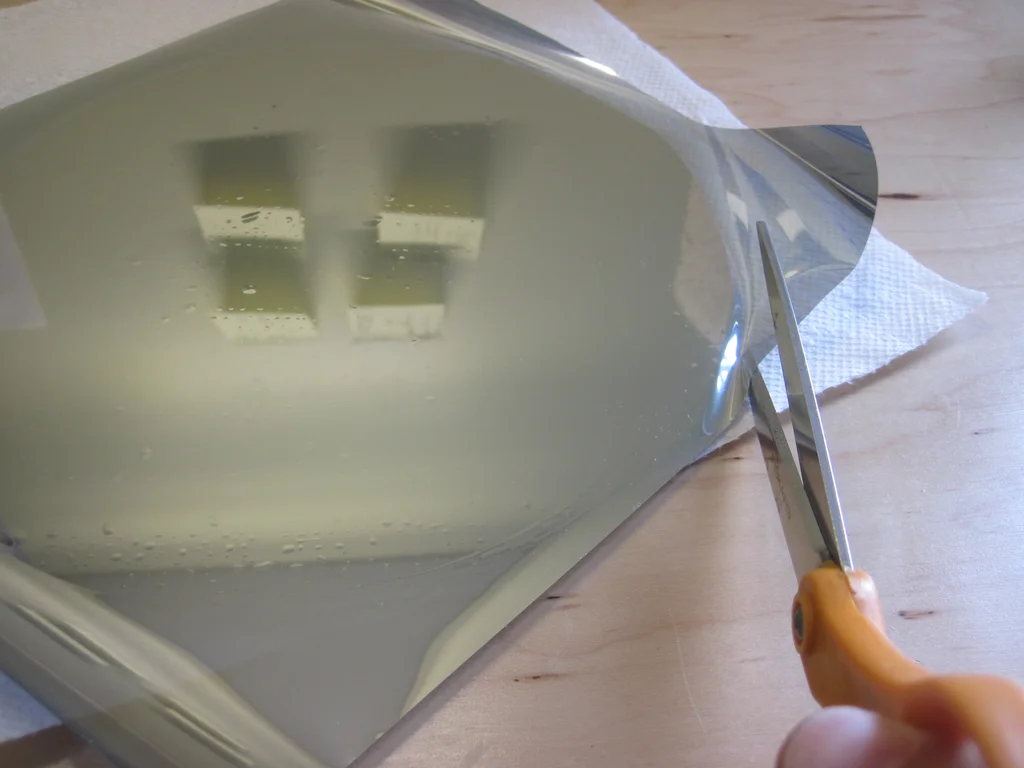

The tinted side of the window has a transparent protective coating , You need to remove it to expose the adhesive . Start at the corner , Carefully peel off the transparent layer with your nails ( This can be painful ), then Carefully Put the mirror tone flat on your acrylic . I think this is the most frustrating part of the whole project / The hardest part - You want to make the hue as flat as possible , There are no bubbles . Big bubbles will be painfully visible in the last mirror , And may detract from hallucinations . I try my best to make the tone as flat as possible , And push them towards the outer edge with your fingertips ( Use paper towels , So I won't stain the color of the window ) Come on “ eject ” Some bubbles . If you really screw up the first time you try , You can strip most of the hue of the window , Then try to lay it flat , The adhesive should not lose its stickiness . If all the other methods fail , You can also cut only one piece of new work .

Once you are satisfied with the appearance and smoothness of the window color , Cut the periphery with scissors , So it will be equal to your acrylic .

step 12: Connect the unidirectional mirror to the frame

There's nothing to see here … Place a unidirectional mirror , The mirror tone is towards * towards *.* I just used electrical tape around the outer edge again . If you want to be more fancy , You can install the one-way mirror on the inside of a slightly larger cardboard cover , Then put it outside the frame .

* ad locum , I just follow the instructions I see on other infinity mirrors . In optics , It should work in either direction , As in step 1 Described in . Maybe acrylic is just harder to scratch / Easier to clean , So it's best to let it face outward … honestly , I'm not sure .

Add tips, questions, comments, downloads

step 13: Light it up !

Plug in the power and start it ! Suppose you are in step 5 In the test LED Light Bar , And there are no major problems in building mirrors , Then it should work as advertised . The above is a bunch of photos I took under different lighting conditions ( The darker the room ,“ Infinite ” The better the result. ), Here is the video of the final product .

I want beginners to understand this as clearly as possible Inscipleable - So if you see something unclear , Or I skip / It implies what you think should be spelled out , Please leave a comment and let me know .

边栏推荐

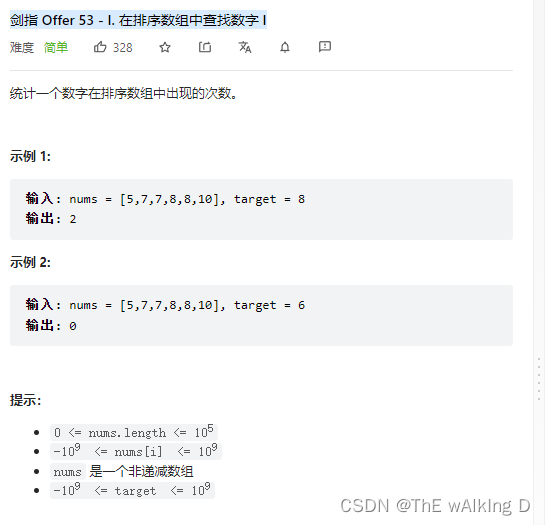

- One question per day 1447 Simplest fraction

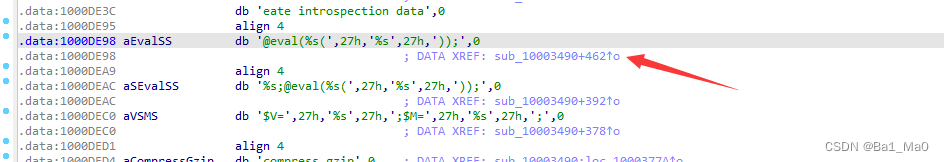

- Analysis of backdoor vulnerability in remote code execution penetration test / / phpstudy of national game title of national secondary vocational network security B module

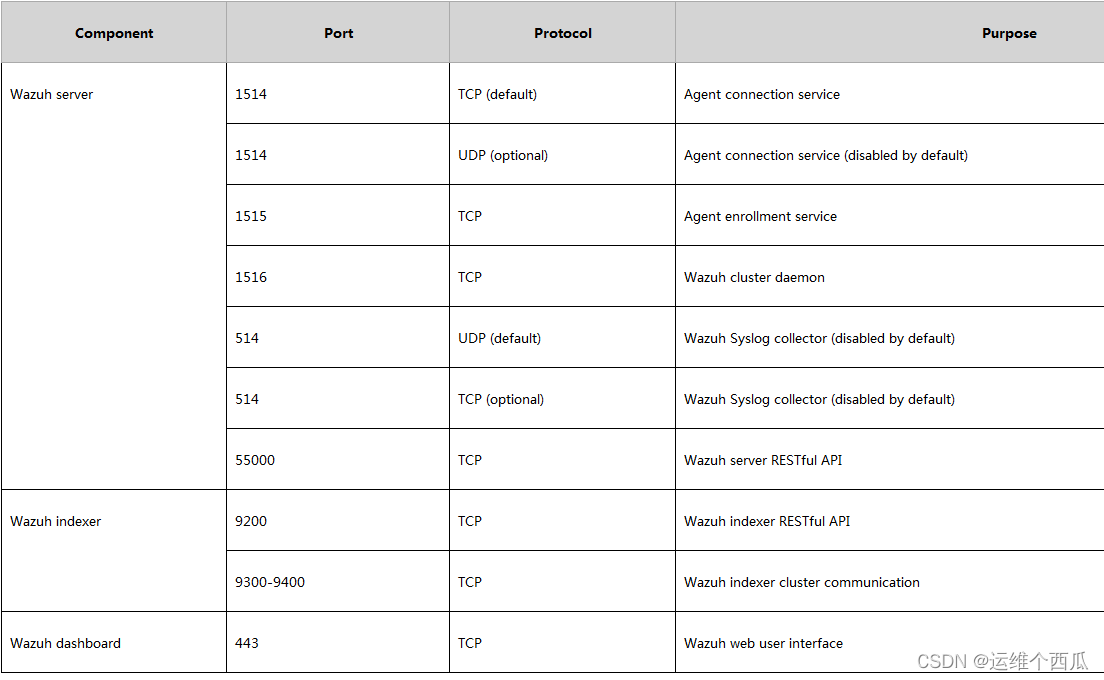

- Introduction et expérience de wazuh open source host Security Solution

- Codeforces Round #732 (Div. 2) D. AquaMoon and Chess

- Educational Codeforces Round 107 (Rated for Div. 2) E. Colorings and Dominoes

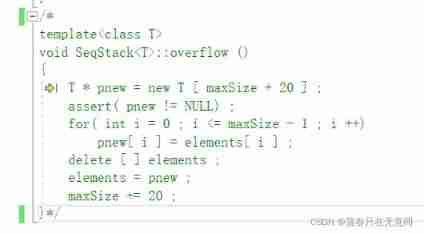

- 剑指 Offer 09. 用两个栈实现队列

- PC register

- Individual game 12

- Sword finger offer 04 Search in two-dimensional array

- One question per day 1765 The highest point in the map

猜你喜欢

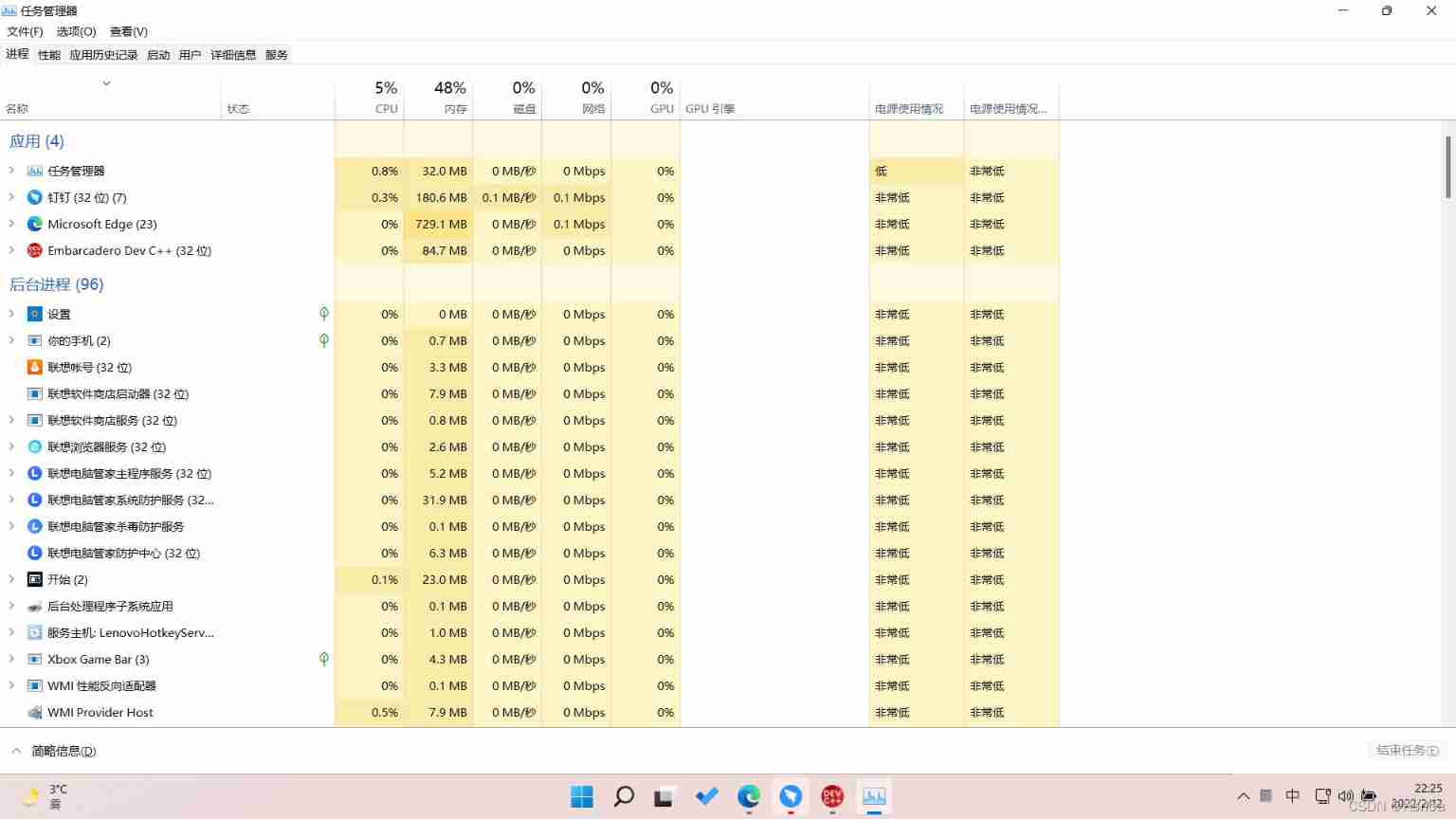

Little known skills of Task Manager

Some common problems in the assessment of network engineers: WLAN, BGP, switch

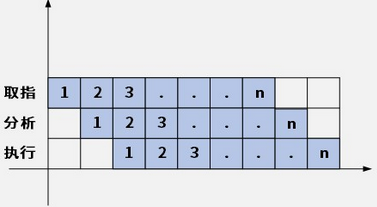

1.14 - 流水线

Introduction et expérience de wazuh open source host Security Solution

Sword finger offer 53 - ii Missing numbers from 0 to n-1

全国中职网络安全B模块之国赛题远程代码执行渗透测试 //PHPstudy的后门漏洞分析

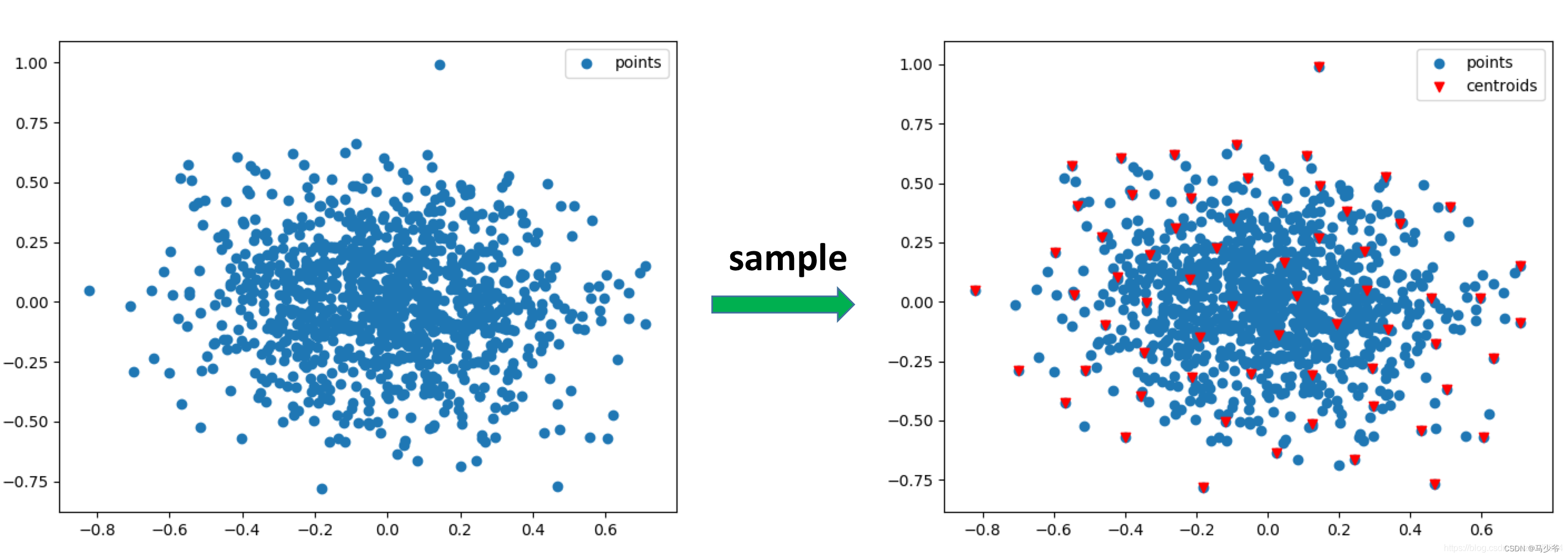

Pointnet++ learning

How to adjust bugs in general projects ----- take you through the whole process by hand

![[jailhouse article] look mum, no VM exits](/img/fe/87e0851d243f14dff96ef1bc350e50.png)

[jailhouse article] look mum, no VM exits

Sword finger offer 09 Implementing queues with two stacks

随机推荐

CF1634 F. Fibonacci Additions

Daily question 1342 Number of operations to change the number to 0

API related to TCP connection

剑指 Offer II 058:日程表

【实战技能】非技术背景经理的技术管理

2022 pole technology communication arm virtual hardware accelerates the development of Internet of things software

PC寄存器

Codeforces Round #732 (Div. 2) D. AquaMoon and Chess

Wazuh開源主機安全解决方案的簡介與使用體驗

Dynamic planning solution ideas and summary (30000 words)

Smart construction site "hydropower energy consumption online monitoring system"

Little known skills of Task Manager

1040 Longest Symmetric String

Time of process

【Rust 笔记】15-字符串与文本(下)

Analysis of backdoor vulnerability in remote code execution penetration test / / phpstudy of national game title of national secondary vocational network security B module

[jailhouse article] jailhouse hypervisor

【Jailhouse 文章】Jailhouse Hypervisor

leetcode-6111:螺旋矩阵 IV

Codeforces Round #715 (Div. 2) D. Binary Literature