当前位置:网站首页>Digital chemical plant management system based on Virtual Simulation Technology

Digital chemical plant management system based on Virtual Simulation Technology

2022-07-07 04:22:00 【Dark blue easy net】

Digital factory is a unique perspective of digital factory technology at the manufacturing planning level , It is the modernization of construction industry PC Intelligent equipment of the factory . The digital factory based on virtual simulation technology is based on the relevant data of the whole product life cycle , Adopt virtual simulation technology to plan the manufacturing process from the factory 、 Simulate different links from construction to operation 、 analysis 、 assessment 、 Statistics 、 Monitoring and optimization , Guide the production planning and site improvement of the factory .

Because the statistical management function of the digital factory system can deal with complex systems that cannot be handled by mathematical models , Can accurately describe the reality of factory production , Identify the key factors that affect the behavior of the system , Therefore, this technology is used in production system planning 、 The design and scheduling stages play an important role . Because of that , Digital factory system has a strong market demand in modern building industrialized component production enterprises . The application functions of the digital factory system include :

1. Inventory management , Estimated through the system , Issue purchase plan , And truthfully record the storage 、 Issue data , Ensure production demand .

2. Design Management , Effectively record the detailed design BIM model data , And associate the information with the corresponding production nodes , Guide production .

3. Production management , Through a reasonable production line 、 Production workshop 、 Simulation configuration of station and team information , Provide feasible production and operation data for production .

Through simulation model-based “ Preview ”, Problems in the design can be found as soon as possible , Reduce changes to the design scheme during construction . Samsung Heavy Industries of South Korea uses DELMIA The software establishes a complete digital shipbuilding system , A virtual shipyard has been established , The whole shipbuilding process can be simulated in a virtual environment . This system is expected to reduce... For enterprises every year 730 $million in expenses . Digital chemical plants will follow the same steps , In the future, it will save costs for prefabricated component factories , Take the low-cost route . Through virtual configuration technology, we can quickly find the problems in the continuous operation of the system , And if you want to find these problems in real systems , Requires long-term testing , At a high cost . The digital factory estimates through the evaluation of each production link , The rework caused by unqualified components is reduced . at present , Domestic component production plants have gradually begun to adopt the digital factory system to assist in planning and establishing the management method of production tasks , Reduce labor costs and production management problems .

In digital factory system ,PC The relevant technologies in the management field of the factory are basically monopolized by foreign products , Due to the early start of foreign construction industrialization , Therefore, a relatively perfect industrialization system has been established in all aspects including factory management . So in our country PC Digital software used in the field of production management in prefabricated component factories is still scarce . Through digital chemical plants in China PC Application and improvement in component factory , In the future, the digital factory system will show more powerful analysis function and more flexible use .

In prefabricated component manufacturing enterprises , The production line is the key link to transform the design intention into products . The digitalization of the component manufacturing process of the production line covers the equipment in different links in the production field 、 Process automation 、 Digital and intelligent . Its development trend also reflects the visualization of component production process 、 Intelligent .

边栏推荐

- easyui出口excel无法下载框弹出的办法来解决

- 别样肉客联手德克士在全国部分门店推出别样汉堡

- Dab-detr: dynamic anchor boxes are better queries for Detr translation

- What is CGI, IIS, and VPS "suggested collection"

- Use dumping to back up tidb cluster data to GCS

- 2022年电工杯B 题 5G 网络环境下应急物资配送问题思路分析

- Food Chem|深度学习根据成分声明准确预测食品类别和营养成分

- 使用Thread类和Runnable接口实现多线程的区别

- The most complete deployment of mongodb in history

- Win11控制面板快捷键 Win11打开控制面板的多种方法

猜你喜欢

Analysis on urban transportation ideas of 2022 Zhongqing cup C

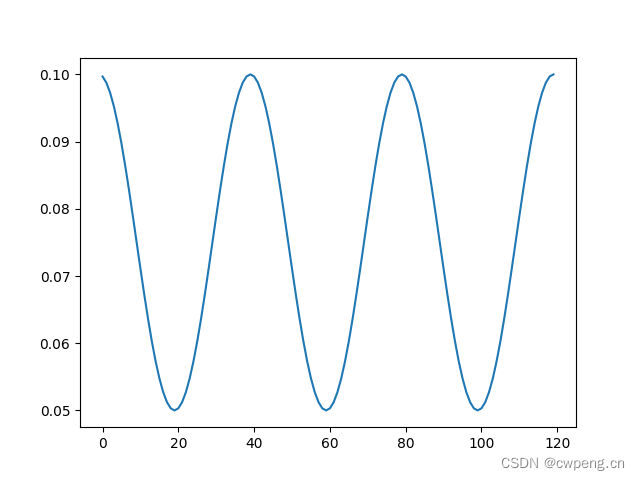

The most complete learning rate adjustment strategy in history LR_ scheduler

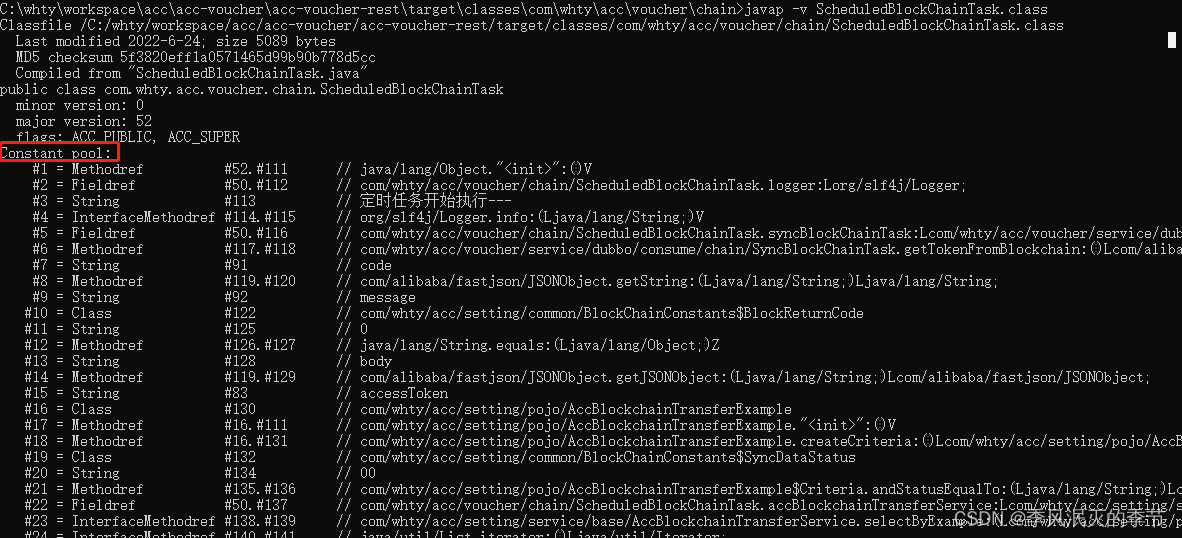

Class constant pool and runtime constant pool

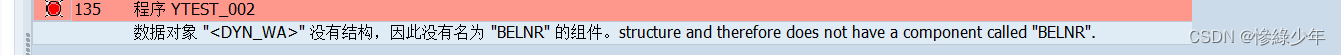

ABAP 動態內錶分組循環

buildroot的根文件系统提示“depmod:applt not found”

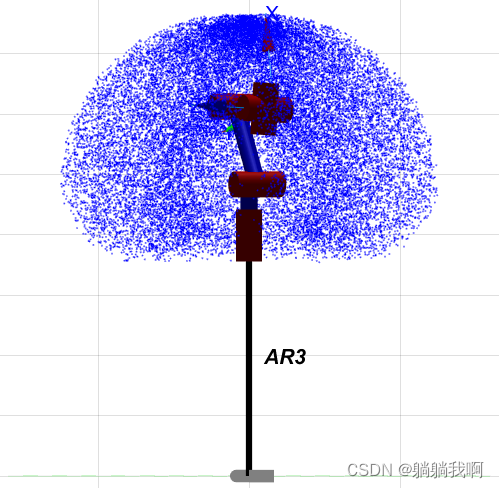

Quick completion guide of manipulator (10): accessible workspace

![[team learning] [phase 34] Baidu PaddlePaddle AI talent Creation Camp](/img/eb/9aed3bbbd5b6ec044ec5542297f3c6.jpg)

[team learning] [phase 34] Baidu PaddlePaddle AI talent Creation Camp

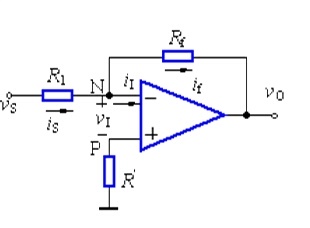

Operational amplifier application summary 1

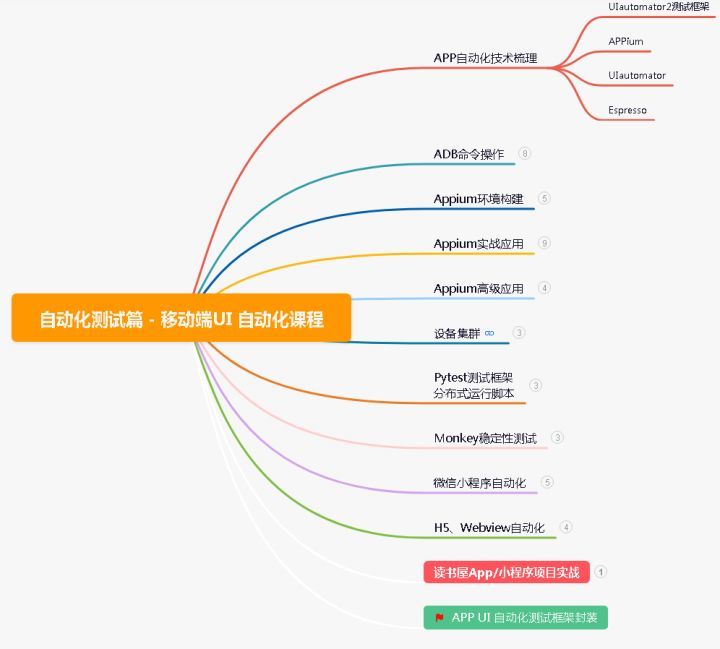

Five years of automated testing, and finally into the ByteDance, the annual salary of 30W is not out of reach

![[record of question brushing] 2 Add two numbers](/img/3b/f8fec79dc2b5088ac57f8d7a18aea6.png)

[record of question brushing] 2 Add two numbers

随机推荐

Analysis on the thinking of college mathematical modeling competition and curriculum education of the 2022a question of the China Youth Cup

英特尔David Tuhy:英特尔傲腾技术成功的原因

主设备号和次设备号均为0

史上最全MongoDB之部署篇

用CPU方案打破内存墙?学PayPal堆傲腾扩容量,漏查欺诈交易量可降至1/30

SSM+jsp实现仓库管理系统,界面那叫一个优雅

手机号国际区号JSON格式另附PHP获取

Highly paid programmers & interview questions. Are you familiar with the redis cluster principle of series 120? How to ensure the high availability of redis (Part 1)?

Collection of idea gradle Lombok errors

2022中青杯C题城市交通思路分析

Implementation of map and set

使用 BR 恢复 GCS 上的备份数据

【编码字体系列】OpenDyslexic字体

Redis源码学习(31),字典学习,dict.c(一)

【写给初发论文的人】撰写综述性科技论文常见问题

kivy教程之设置窗体大小和背景(教程含源码)

史上最全MongoDB之安全认证

杭州电 3711 Binary Number

POJ培训计划2253_Frogger(最短/floyd)

The most complete deployment of mongodb in history

http://www.gdblue.com/q_news/shownews.php?lang=cn&id=609

http://www.gdblue.com/q_news/shownews.php?lang=cn&id=609