当前位置:网站首页>Get twice the result with half the effort: automation without cabinet

Get twice the result with half the effort: automation without cabinet

2020-11-06 01:47:00 【Vibrator chain】

“ Do more with less money ” It is the common goal of many industrial enterprises , In particular, today's factories are under pressure to maintain high production and reduce machine floor space , More information on the vibrator chain .

Modular units are becoming more mature , It can meet the needs of modern production . They can be implemented faster in new spaces , It can also be integrated into existing production lines , This enables manufacturers to respond more quickly to changing conditions and demands , So as to provide more flexibility for customers .

One of the little-known advantages of modular units is how they can support the recovery of valuable floor space in the factory . Among manufacturers , More and more people pay attention to the real estate of machines , Or how square meters of factory area increase revenue . These considerations go beyond the bottom line , Factors such as throughput and environmental impact are also key considerations .

Except for the obvious , Smaller machines take up less space , If implemented correctly , This kind of equipment can increase the manufacturing capacity without expanding the facilities .

However , In addition to the advantages of modular units , There are still challenges . They include how to best connect , Integrating and driving these machines . For such needs , We have to turn to new ways of machine design and function .

No panel system

One such method involves a mechanical control panel . Control panels sometimes take up a few meters of space in a production line - Otherwise it will be dedicated to the production of machine space . Besides , This is often the case between manufacturers : The goal is to reconfigure or expand the production line , As a result, the number of equipment installed is increasing .

therefore , under these circumstances , Saving space for control panel size is the way forward . As the number of devices used in the control panel increases , Because it's more advanced , More complex machine functions , This is a challenge . For all that , To make OEMs (OEM) And end users benefit ,Beckhoff It's a challenge .

In one example , Beifu company and a world famous packaging company OEM Manufacturers work closely together .Beckhoff Invited to support cost reduction throughout the life cycle of the machine , From design , Purchasing and manufacturing to commissioning , Transportation and field installation . Final , Customers want to reduce the floor space of the equipment .

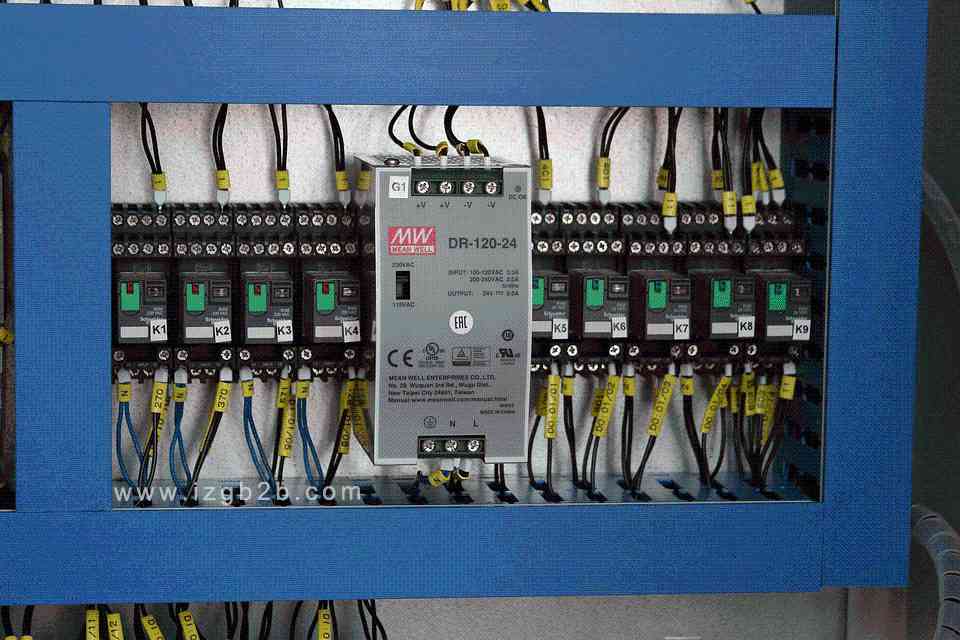

The final solution is to remove the control cabinet , And build automation components into the structure of the machine itself . The concept of a faceless machine is Beckhoff Of “ No cabinet Automation ” A supplement to the concept , This minimizes the size of the control cabinet . before , There are controllers in the cabinet , Servo drives and inputs / Output (I / O) Space needs of , Now automation without the concept of a cabinet can greatly reduce space requirements .

Install side by side

Use AMP8000 Servo drive , The power electronics of the machine have been moved directly to the machine . This reduces the space required in the control cabinet to basic functions , For example, input power , distribution , Isolators and fuses .

More specifically , The system integrates the servo driver with high safety level directly into the servo motor in a very compact design . This unique technology eliminates the need to increase the size of the motor frame at a given power , This sets the system apart from biff's competitors , And it's good for the modular machine concept .AMP8000 The system fully integrates drive technology into most individual machine concepts . let me put it another way , The system can flexibly adapt to the personalized needs of customers , Its design flexibility can minimize the space requirement in the control cabinet .

One cable Automation

Beckhoff Of “ Single cable solution ” yes AMP8000 A supplement to . The idea is , A cable can go through the machine , In order to connect a plurality of distributed servo drivers and I / O System . Greatly reduce the wiring of plug and socket , It also reduces wiring time and errors .

The key technology here is EtherCAT P, This is a EtherCAT A new development of technology in the wiring level .“ P” On behalf of the power supply , And allows the use of standard four wire Ethernet cables , Not just for data , And it's also used for two electrically isolated , It can be switched separately 24 v (3 Amp) Power Supply .

Use EtherCAT P, Can connect multiple EtherCAT equipment , And you can use a simple topology to implement complex machines or machine production lines . therefore , Just one input cable / Output (I / O) And other field equipment ( Including servo driver ) And power it up .

Beckhoff EtherCAT PI / O The product portfolio is very comprehensive . There is no need to use multiple connecting cables between the control cabinet and the machine , It takes only one cable to connect to AMP8805 Distribution module , Because of every AMP8000 The distribution servo driver only needs a short time to connect to the distribution module . cable . Use EtherCAT P, The cable path to the motor can be arranged more clearly , And minimize the space requirements in the control cabinet .

Besides , Only one cable type is required for the entire system wiring . and , Pre assembled system cables greatly reduce logistics , The time and cost of wiring and commissioning , And minimize the risk of error .

For many people , Subtraction is not natural . however , With the right equipment , It is certainly possible for manufacturers to make more profits with less money , More information on the vibrator chain .

版权声明

本文为[Vibrator chain]所创,转载请带上原文链接,感谢

边栏推荐

- 一篇文章带你了解CSS对齐方式

- Introduction to quantitative investment and Trading (Python introduction to financial analysis)

- Free patent download tutorial (HowNet, Espacenet)

- I've been rejected by the product manager. Why don't you know

- keras model.compile Loss function and optimizer

- What if the front end doesn't use spa? - Hacker News

- 用一个例子理解JS函数的底层处理机制

- Summary of common string algorithms

- Vue.js Mobile end left slide delete component

- Introduction to Google software testing

猜你喜欢

Thoughts on interview of Ali CCO project team

How to customize sorting for pandas dataframe

A course on word embedding

游戏主题音乐对游戏的作用

I've been rejected by the product manager. Why don't you know

vue任意关系组件通信与跨组件监听状态 vue-communication

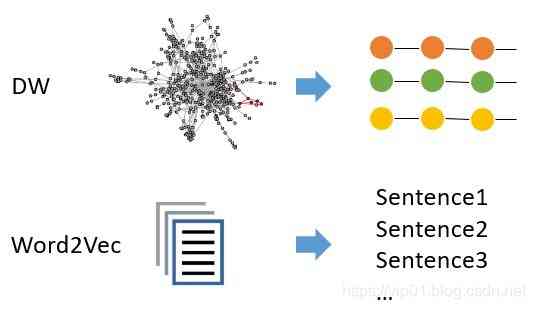

Brief introduction and advantages and disadvantages of deepwalk model

C + + and C + + programmers are about to be eliminated from the market

keras model.compile Loss function and optimizer

Read the advantages of Wi Fi 6 over Wi Fi 5 in 3 minutes

随机推荐

Three Python tips for reading, creating and running multiple files

有了这个神器,快速告别垃圾短信邮件

Recommendation system based on deep learning

The difference between gbdt and XGB, and the mathematical derivation of gradient descent method and Newton method

Thoughts on interview of Ali CCO project team

6.4 viewresolver view parser (in-depth analysis of SSM and project practice)

[JMeter] two ways to realize interface Association: regular representation extractor and JSON extractor

文件过多时ls命令为什么会卡住?

大道至简 html + js 实现最朴实的小游戏俄罗斯方块

一篇文章带你了解CSS对齐方式

Pattern matching: The gestalt approach一种序列的文本相似度方法

I think it is necessary to write a general idempotent component

Summary of common string algorithms

Python基础数据类型——tuple浅析

How to encapsulate distributed locks more elegantly

Vite + TS quickly build vue3 project and introduce related features

Building and visualizing decision tree with Python

这个项目可以让你在几分钟快速了解某个编程语言

6.3 handlerexceptionresolver exception handling (in-depth analysis of SSM and project practice)

What problems can clean architecture solve? - jbogard